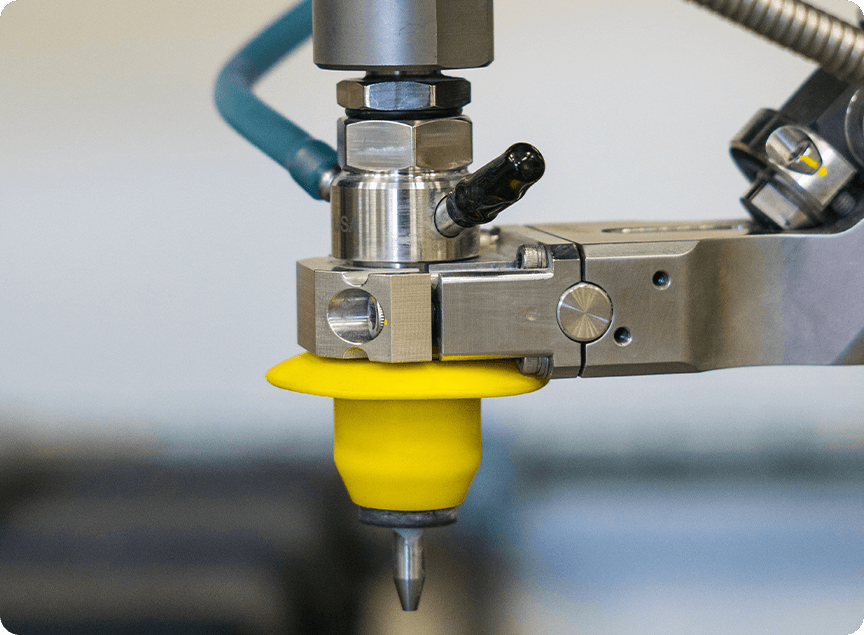

Pivot+™

Durable, Compact, & Streamlined Bevel Cutting

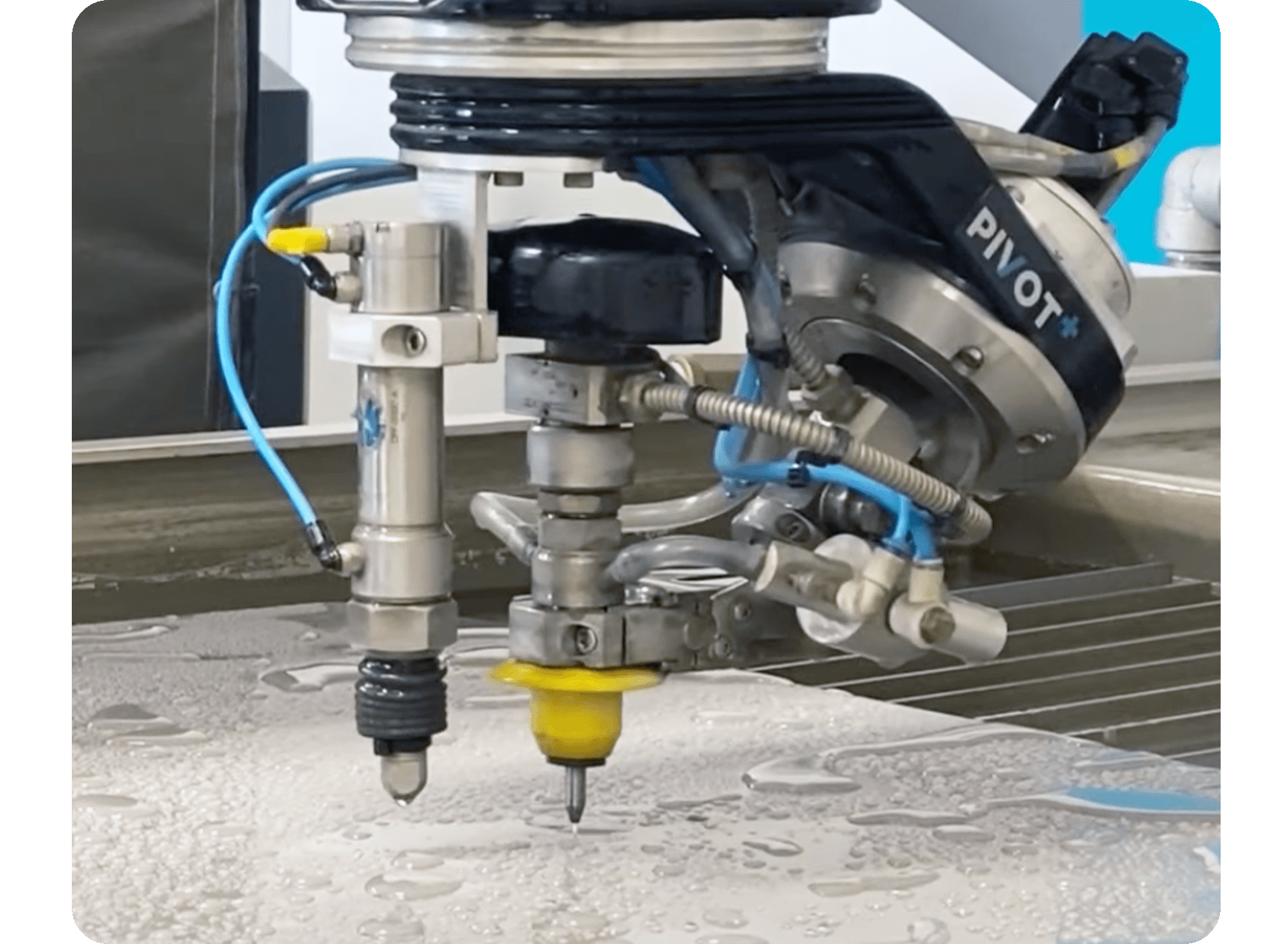

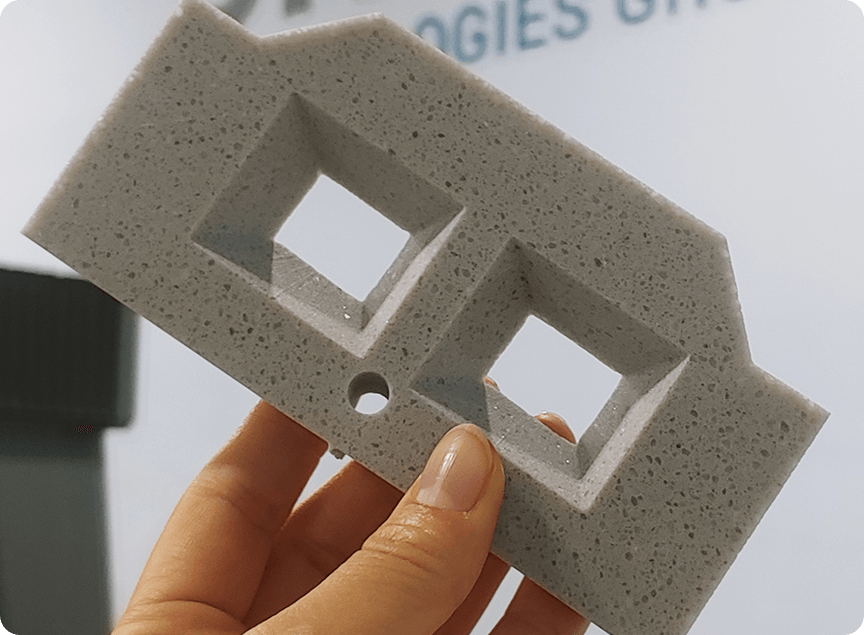

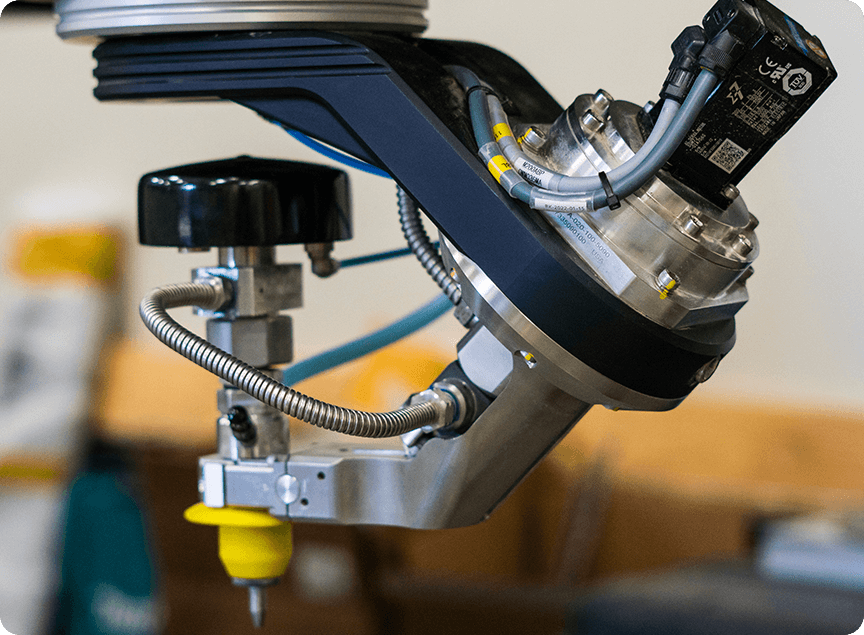

Add a new dimension to your waterjet bevel cutting capabilities and open the door to fresh opportunities with Pivot+™ Waterjet. Get multi-axis, taper compensation cutting with accuracy and flexibility. Designed by the same engineers who developed Dynamic Waterjet® XD (the world's premier 5-axis cutting solution), Pivot+ is a robust, compact cutting head.

Key Features

Multi-Axis Cutting

Pivot+ is a robust, multi-axis cutting solution with taper compensation.

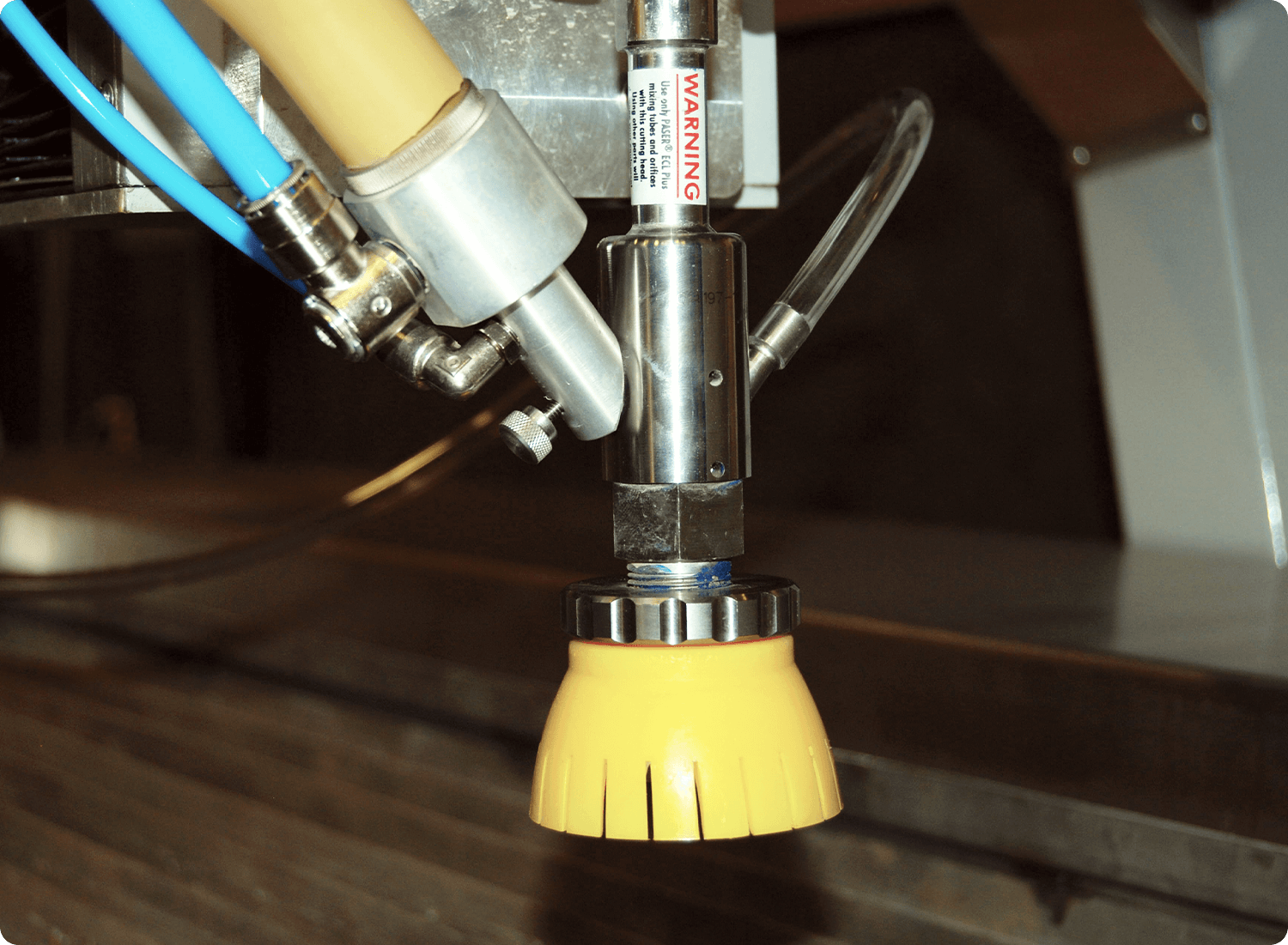

Compact Design

Designed by Flow cutting technology experts, the compact design delivers maximum cutting area.

High Speed Motion

Exceptional throughput with high-speed wrist motion. Pivot+ offers fast set up and calibration to get you into production fast.

Durable

With an IP67 rating, Pivot+ is made to withstand daily, rigorous use in harsh environments.

Specifications

Up to 60° of motion for bevel cutting

IP67 rating for durable operation

High speed wrist — up to 120 RPM

Exclusively available on Flow's Mach 200 waterjet systems

Integrates with FlowMaster® and FlowXpert® software suites

Core Component Options

UltraPierce™ Vacuum Assist

Learn More