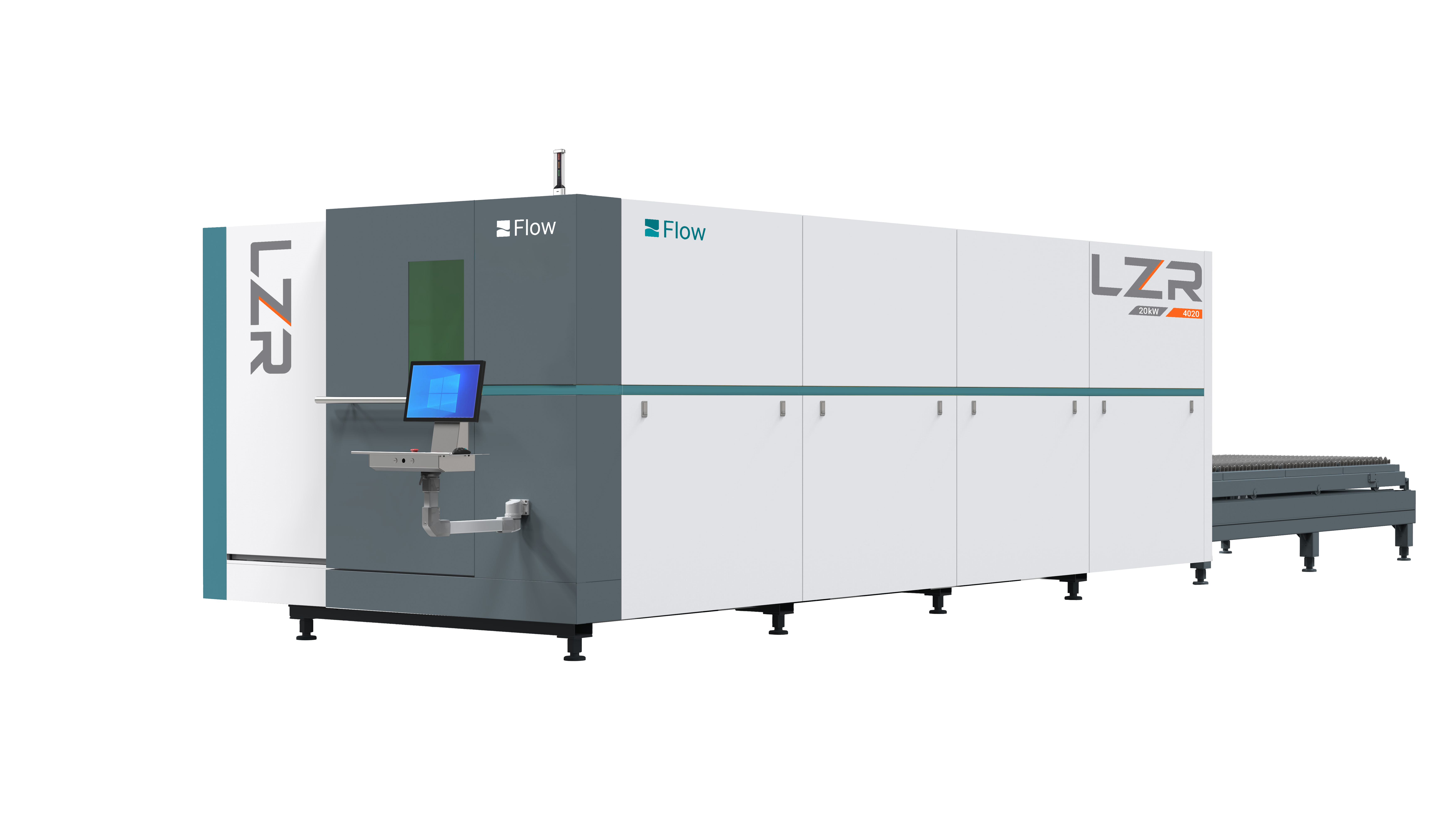

LZR

Fast Forward.

Flow LZR series delivers accuracy on both thin and thick materials. Built for high-volume production, its advanced dual-drive gantry and fast automatic shuttle table system ensure seamless, efficient operation.

Key Features

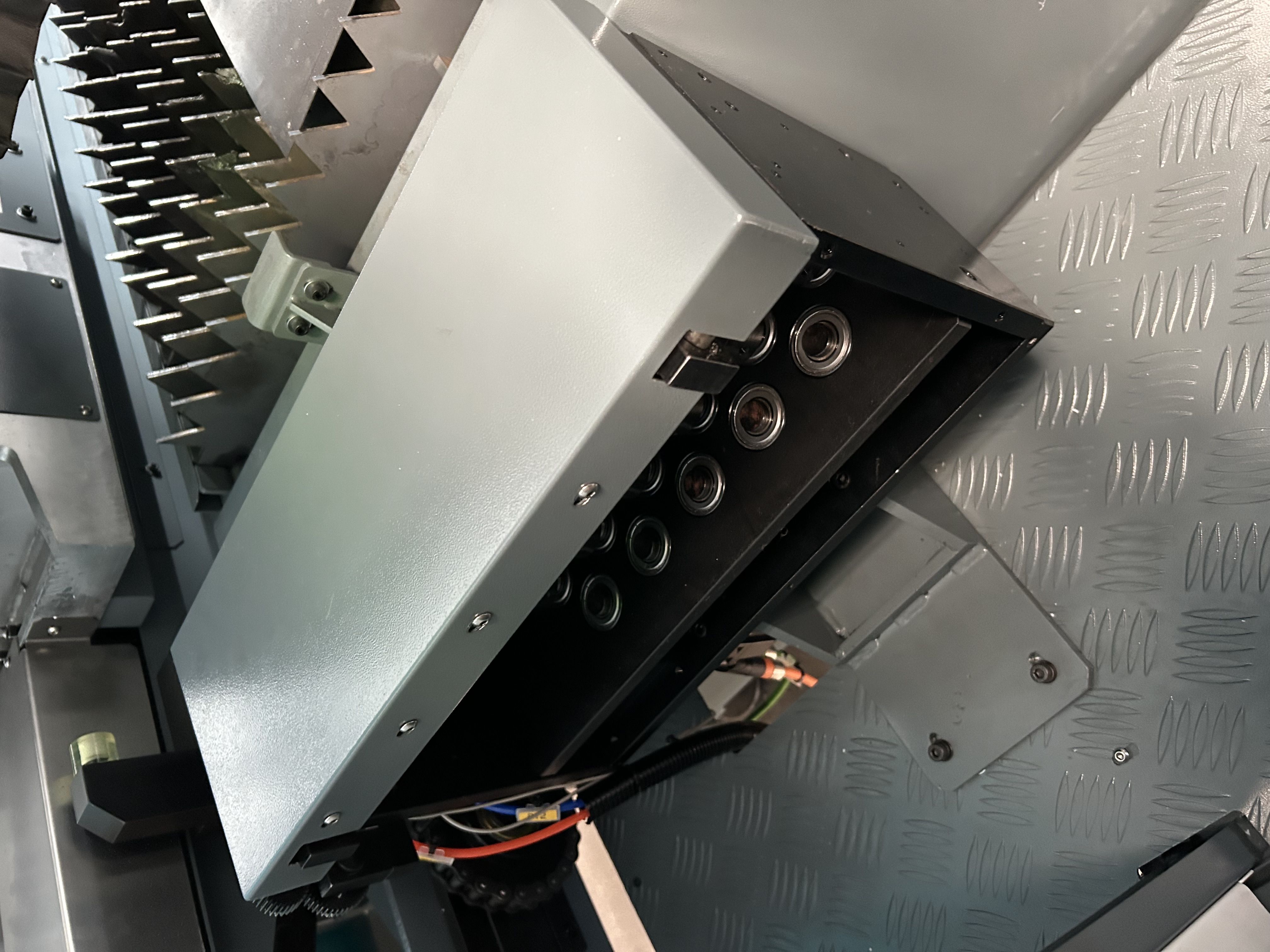

Dual-Drive Gantry

AC Servo actuated, dual-drive gantry maximizes stability, reduces vibration at high speed, and ensures part quality.

Dual-Pallet (LST) Load/Unload

Standard laser shuttle tables provide swift exchange for sheets as well as a gateway to material handling automation.

Automatic Nozzle Changer

Systematic swap of cutting head tips for new materials and back-up replacements for continuous production runs.

Automation Options

Seamless integration utilizing the standard laser shuttle tables with minimum idle time; equal to a single exchange.

LZR Series Sizes

General Specifications

LZR 4020: 158 x 79 in

LZR 4020: 398 x 119 x 85 in

Core Component Options

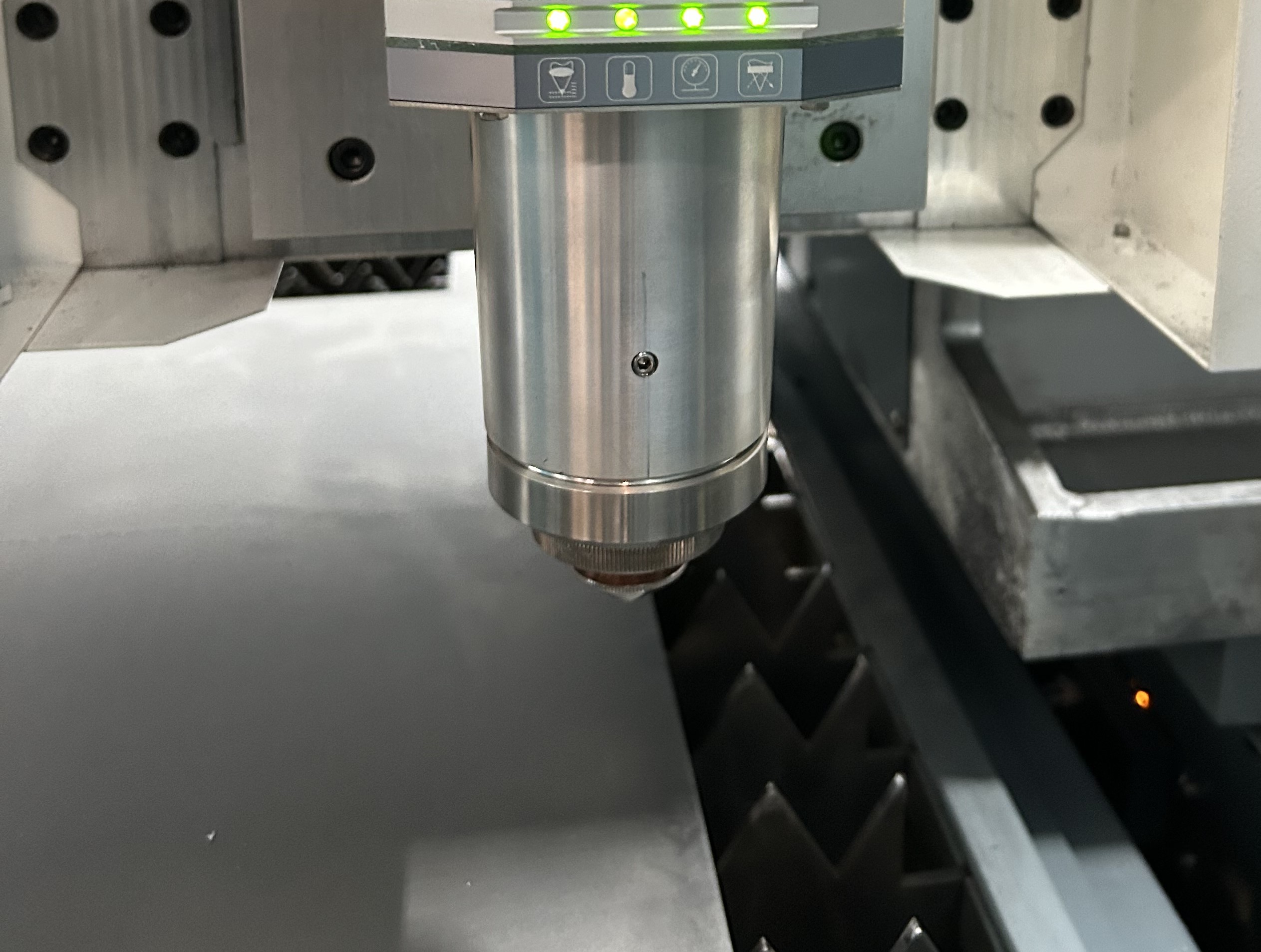

Cutting Head Technology

Auto-Focus Cutting Head

Adjusts for varying thicknesses in piercing and cutting with a capacitive sensor for slight variations in material plane.

Software

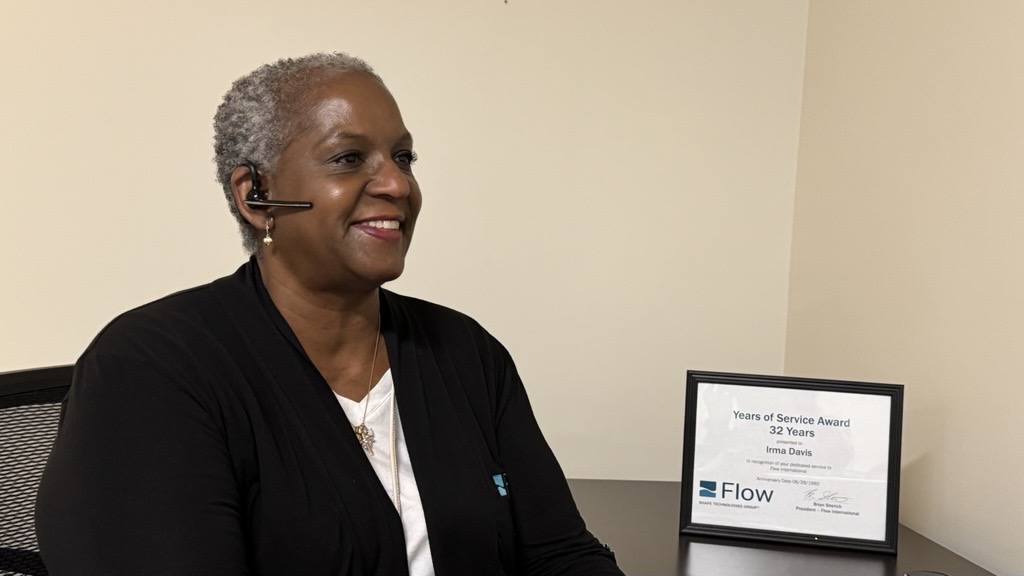

Service Guarantee

We are committed to providing you with the tools you need to keep your system running at its best. Professional training is available in both classroom settings, as well as on-site.

You might also like…

Article

Waterjet + Laser = Yes, Please

Often times waterjet and laser are pitted against each other as competitive technologies, vying for important space on the production floor of fabrication or machine shops. But what if these two state-of-the-art technologies didn’t compete for cut time, but complemented one another?

Read More

Article

How Does Waterjet Compare to Laser, Plasma, or EDM

There are numerous cutting techniques in metal fabrication. And if you’re reading this, you’ve probably asked yourself, ‘Which is right for me?’ Waterjet, laser, plasma, and Electrical Discharge Machining (EDM) are all popular solutions for fabricators and machine shops. However, what’s right for you depends on the type of work you’re doing and your desired outcomes. We’re breaking down each technology to help inform your decision for which process is right for you.

Read More