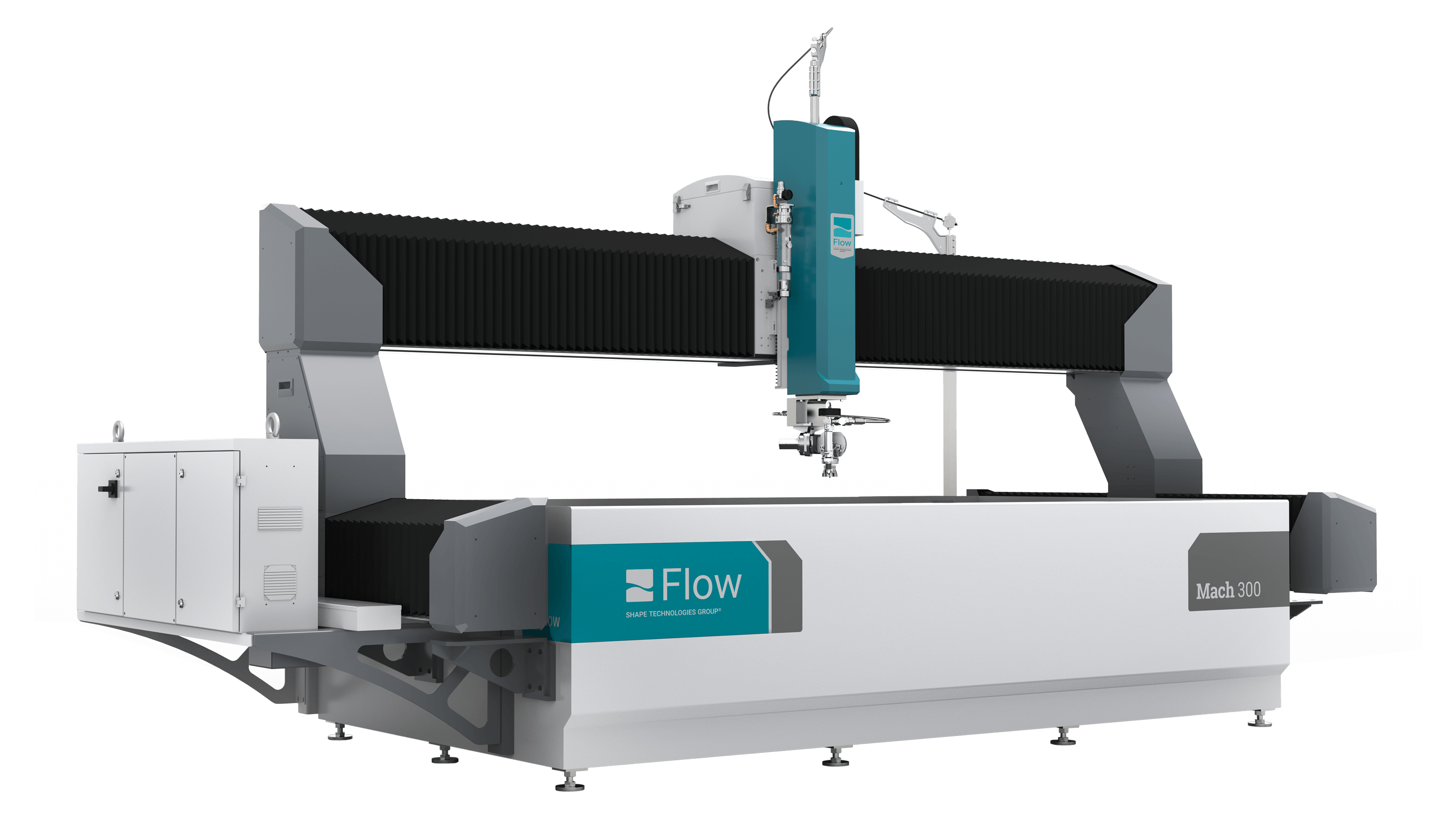

Mach 300

Move Forward.

The Mach 300 is purpose-built to deliver reliable performance that you can depend on. The system is a no-nonsense waterjet solution that is efficient and practical. Combining advanced Flow waterjet technology into a small package, the Mach 300 minimizes impact on shop floor space – and your wallet.

Key Features

Productivity Made Easy

The Mach 300 handles high production needs with ease. Dynamic Waterjet® brings the Mach 300 to the next level for efficient and accurate cut parts. With small footprint options and a quick installation, Mach 300 makes waterjet easy.

Purpose-Built for Value

The Mach 300 is purpose-built and value focused, bringing a new kind of ROI to the waterjet world. Advanced Flow technology and all-in-one steel construction create a robust foundation for cutting performance.

Roll-Around Operator Station

Take your operator station with you as you work, giving you the flexibility to move freely about your waterjet.

Support You Can Count On

Delivering productivity and reliability requires world class support. From the safety light curtains that come standard on every Mach 300 to our attentive Flow certified technicians who are ready to support you when needed – we have the right people and programs to support you.

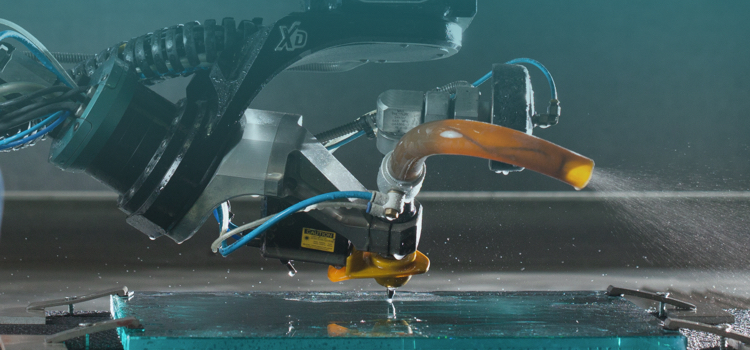

See the Mach 300 in Action

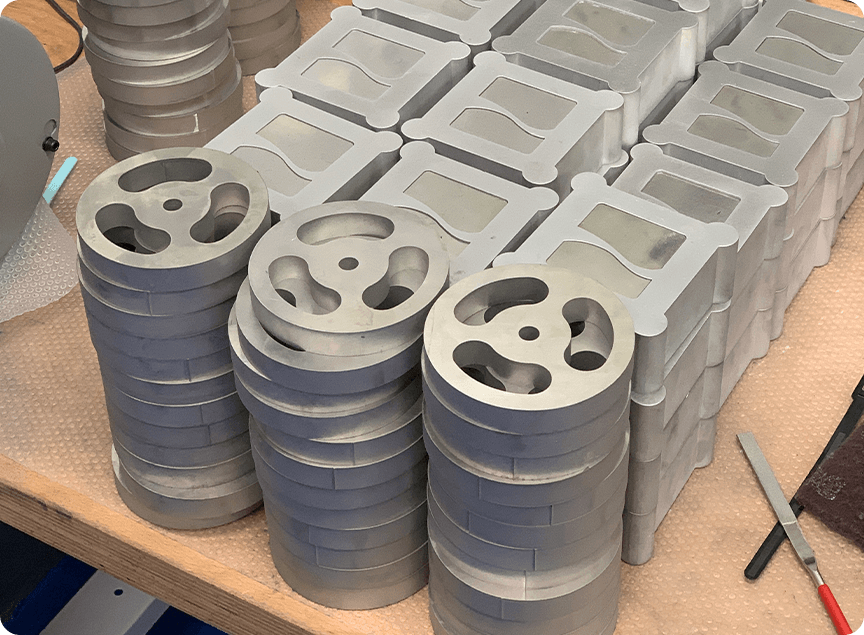

Go from pure water to abrasive cutting in one system with minimal tooling changes, and maximize your ability to cut a variety of materials such as plastics, gaskets, and metals.Mach 300 Series Sizes

General Specifications

Mach 300 3015: 3 m x 1.5 m

Mach 300 3015: 10' x 5'

Core Component Options

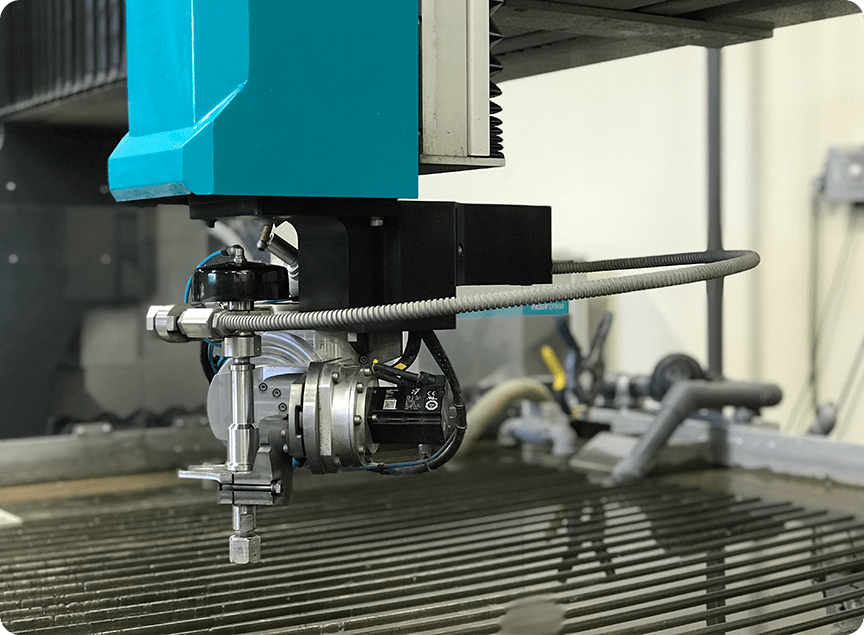

Cutting Head Technology

Pure Waterjet

Hair-thin pure waterjet stream ideal for cutting soft materials.

Standard Waterjet

Uses garnet abrasive to cut virtually any hard material. Learn more.

Dynamic Waterjet®

Three times faster and more accurate than Standard Waterjet. Learn more.

Pump Technology

HyPlex® Prime

60,000 psi [4,150 bar]

The highest pressure, most advanced direct drive pump available today, with pressures rated at 60,000 psi [4,150 bar]. Learn more.

MotoJet®

60,000 psi [4,150 bar]

With continuous operating pressure at 60,000 psi [4,150 bar], the MotoJet is built for the demands of high-production environments. Learn more.

MotoJet® X

60,000 psi [4,150 bar]

Engineered to maximize uptime, minimize maintenance, and outlast and outperform the rest. It's the longest lasting pump in the industry. Learn more.

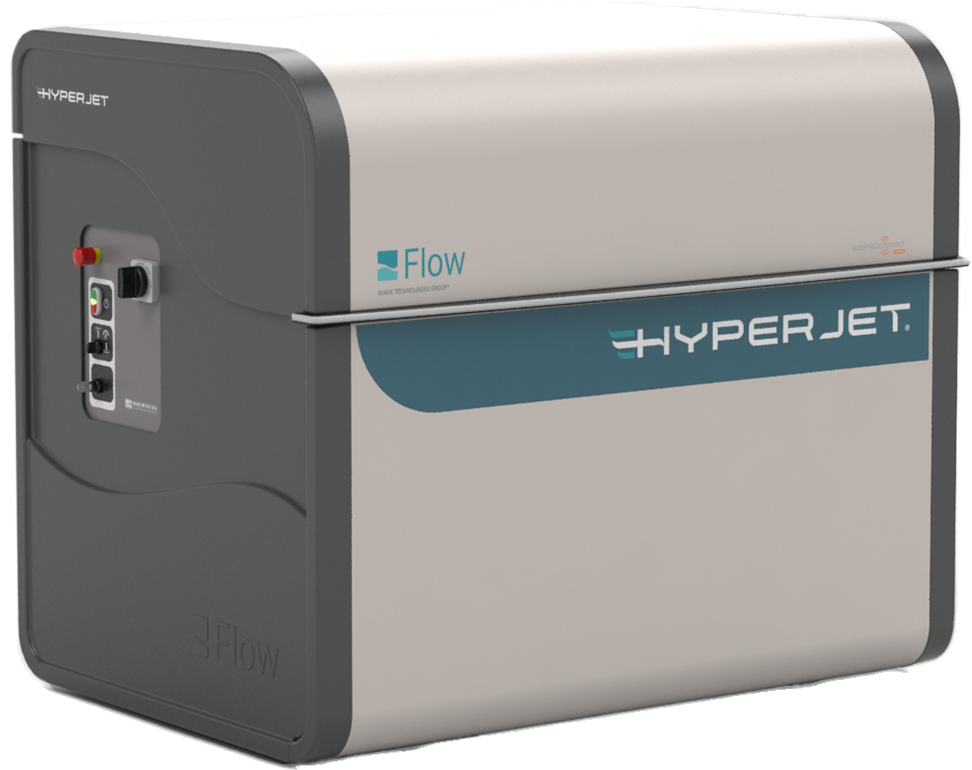

HyperJet®

94,000 psi [6,500 bar]

Provides maximum productivity with continuous operating pressures of 87,000 psi [6,000 bar]. Learn more.

Software Suites

FlowMaster

The FlowMaster software suite, consisting of FlowCut, FlowPath, and FlowNest has everything you need to design and cut 2D waterjet parts. Learn more.

FlowXpert

The FlowXpert software suite, consisting of FlowXpert Infinity, FlowCut, and FlowNest gives you all the tools you need for both 2D and 3D cutting. Learn more.

Service Guarantee

We are committed to providing you with the tools you need to keep your system running at its best. Professional training is available in both classroom settings, as well as on-site.

Best for these Applications

You might also like…

Webinar

10 Critical Factors You Can't Ignore When Considering Waterjet

When it comes to waterjet, there are a wide variety of options and configurations to consider. Guidance from waterjet experts is key understanding all the possible variables so you can make the exact right choice for your business.

Watch Now

Article

What Pressure Is Best for My Business and Application?

Waterjet buyers often wonder what amount of pressure is right for their unique application. We’re outlining the pros and cons of different pressure levels and how to decide which is best for you.

Read More