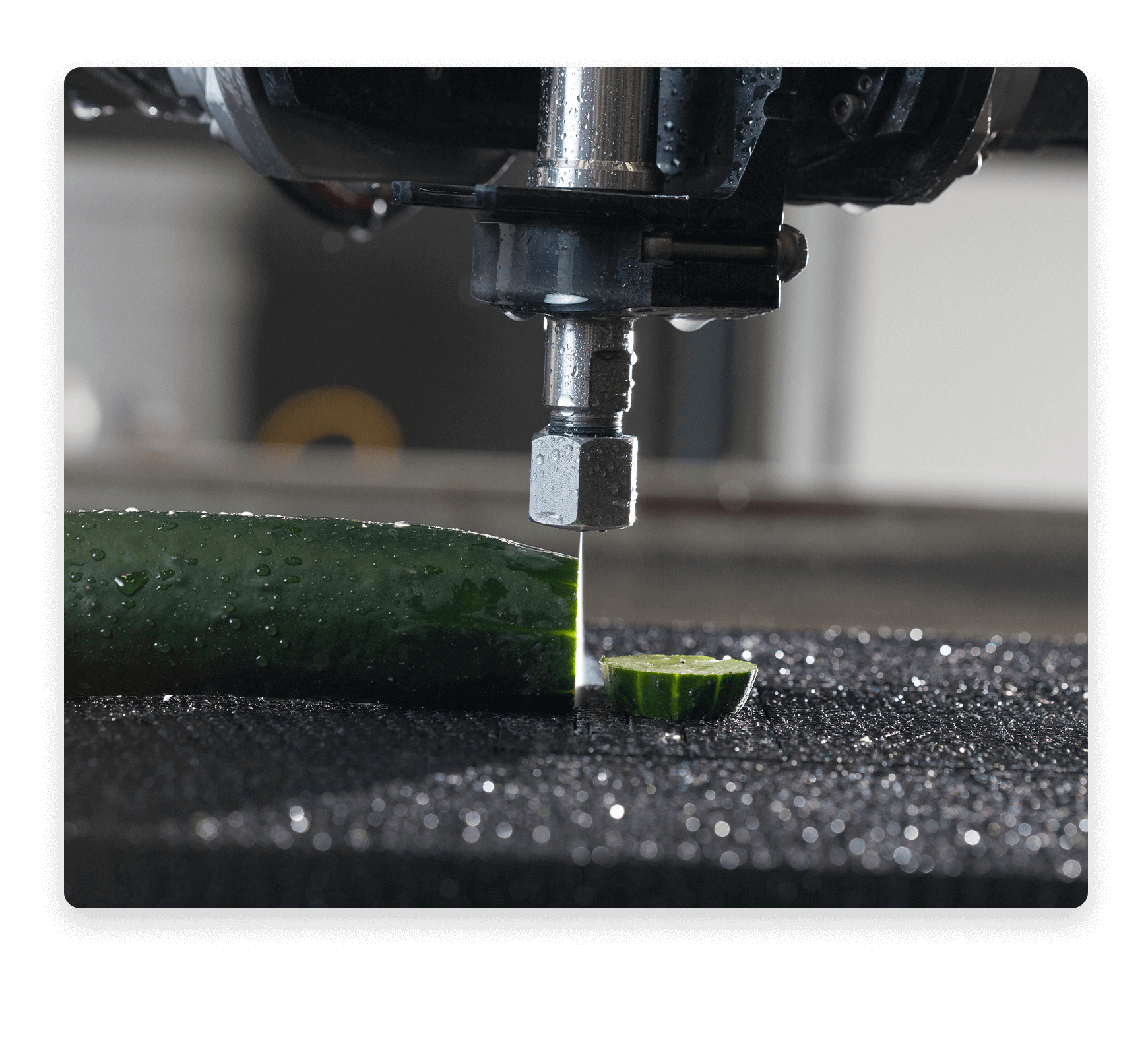

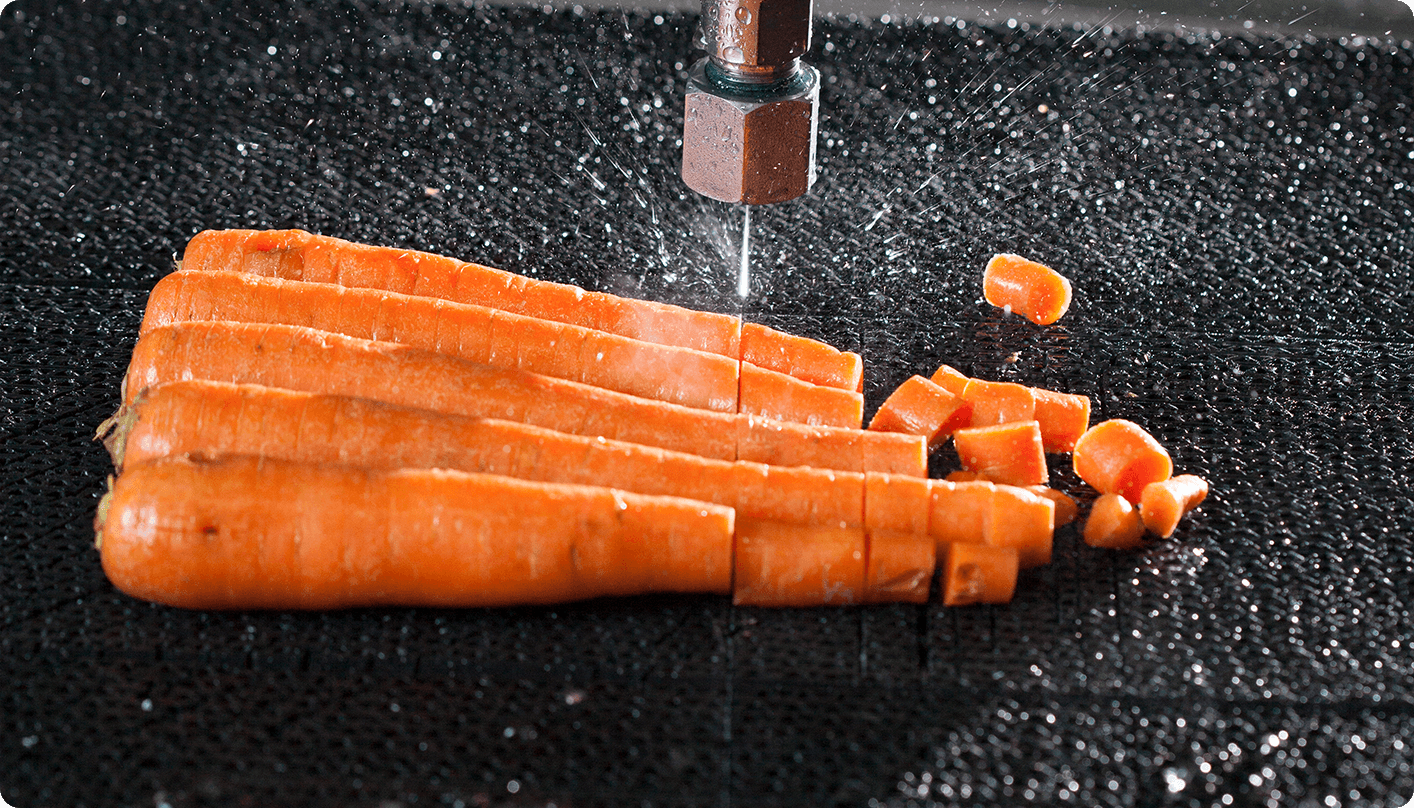

Cutting Foods with Waterjet

Pure waterjet cutting is a USDA-approved method that offers a number of productivity and sanitation advantages over other cutting methods. In fact, cutting and portioning of foods is one of the earliest waterjet applications. Meats, poultry, fish, produce, pastries, frozen foods, and even candy bars are being cut today with our ultrahigh-pressure waterjets.Not sure a waterjet can handle your material?

The Best Edge

With no blade or metal cutting, there is no bacterial transfer from food to food or tool to food, and no downtime for sharpening. The cut quality is usually extremely high, with a clean edge free of smearing or tearing.

Minimal Kerfs

The width of cut ranges from 0.004 to 0.009" for common food cutting application. The extremely small kerf, similar in thickness to a typical human hair, means almost no waste; and when the application requires, very intricate cutting.

Key Benefits to Cutting Foods with Waterjet

- Cuts with only water

- Simple to integrate Flow waterjet systems with food cutting machinery

- No bacterial transfer

- Easily accommodate product changes

- Operator safety

- Built for heavy, industrial use to support 24/7 operation