Cutting Stacked Materials with Waterjet

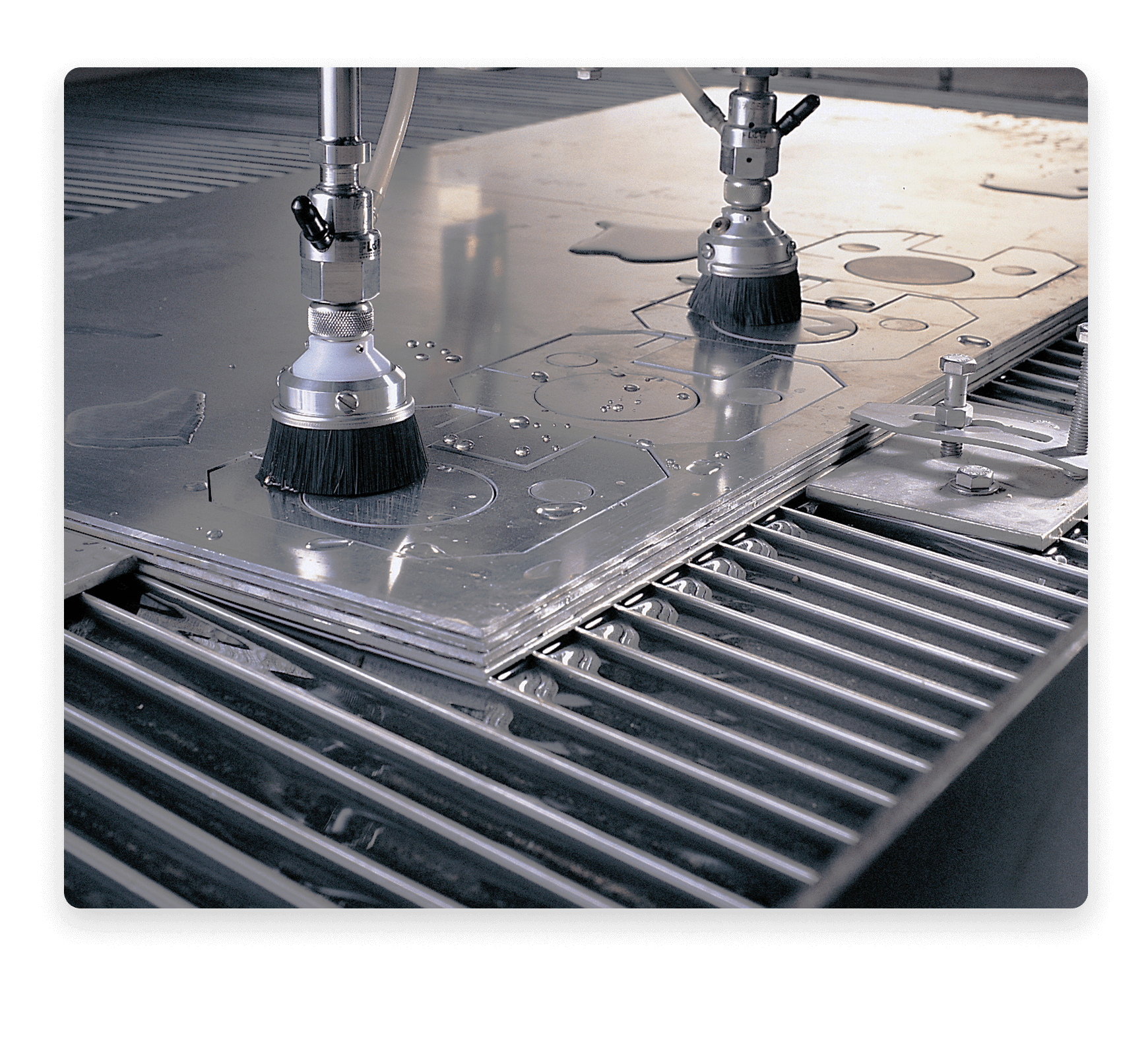

Stack cutting is a unique feature to waterjet applications. Because a waterjet cuts via supersonic erosion process it is possible to stack and cut several layers of material all in one pass. All Flow waterjet systems are capable of stack cutting up to several inches in material.Not sure a waterjet can handle your material?

The Best Edge

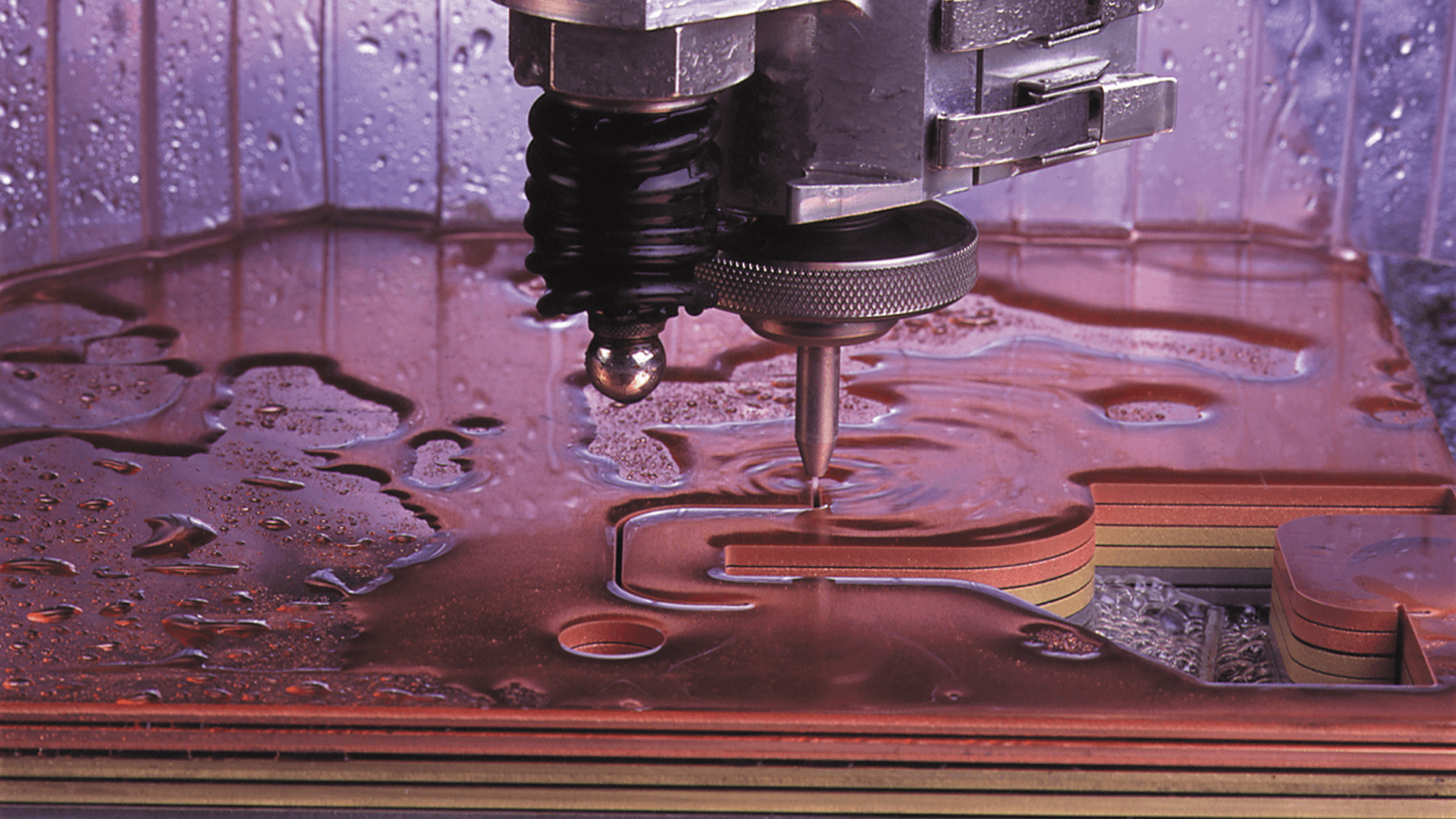

Because waterjets are a cold cutting process, materials can be stacked and cut without the risk of melting layered materials together, leaving a perfectly clean waterjet cut edge.

Minimal Kerfs

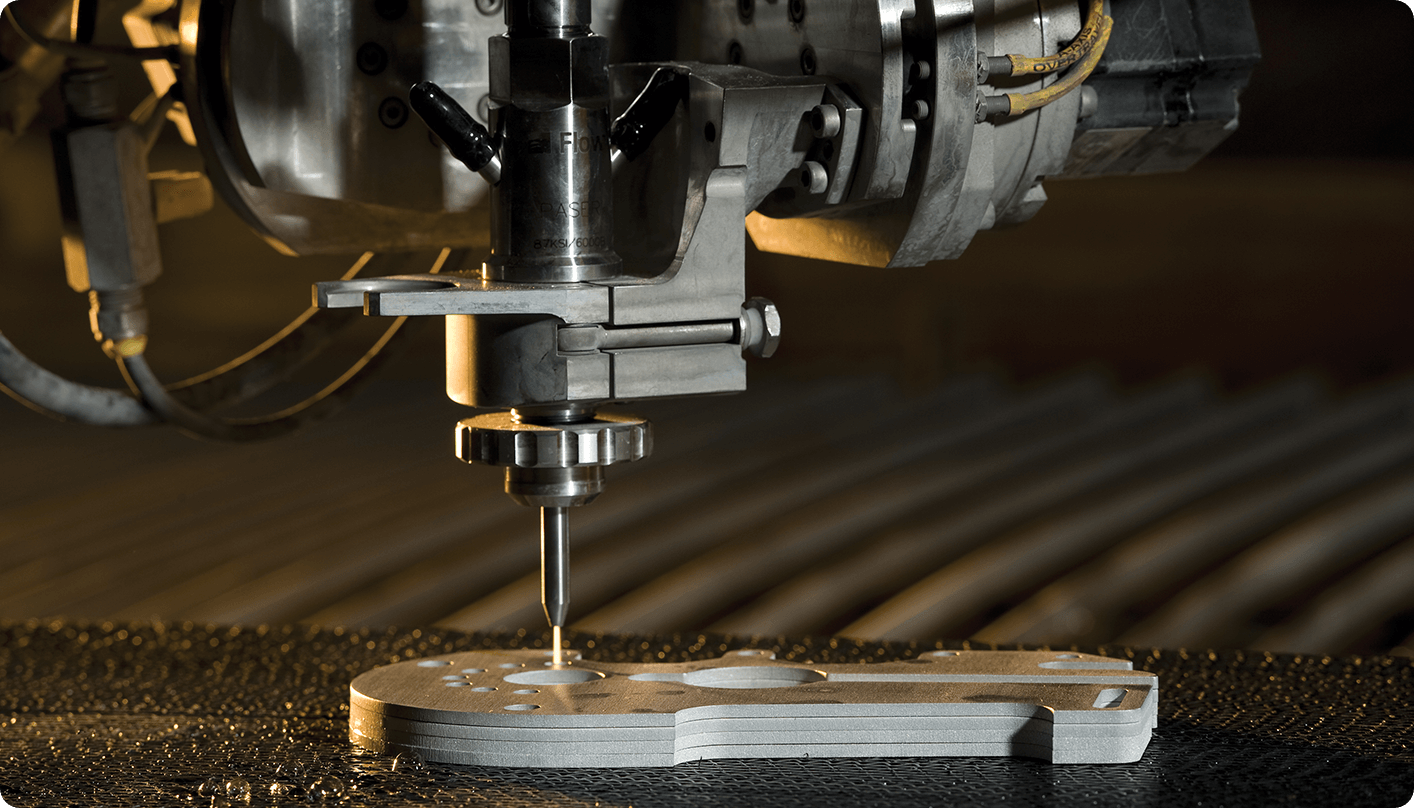

The thin kerf width of an abrasive waterjet allows you the ability to cut stacked material well up to several inches thick, it is important to note that the thicker the stack cut, the larger the variable between the top and bottom cuts.

Key Benefits to Cutting Stacked Materials with Waterjet

- Increased productivity, fast cutting and high-quality parts

- Minimal kerf allows incredible detail

- Raw material savings — reduced scrap

- No need for extensive part clamping, minimal lateral or vertical forces

- Single-pass cutting, depending on material thickness

- No thermal damage

- Net or near-net cutting, little or no hand finishing