Job Shops & Contract Cutting

Cut virtually any material, virtually any shape with a Flow waterjet

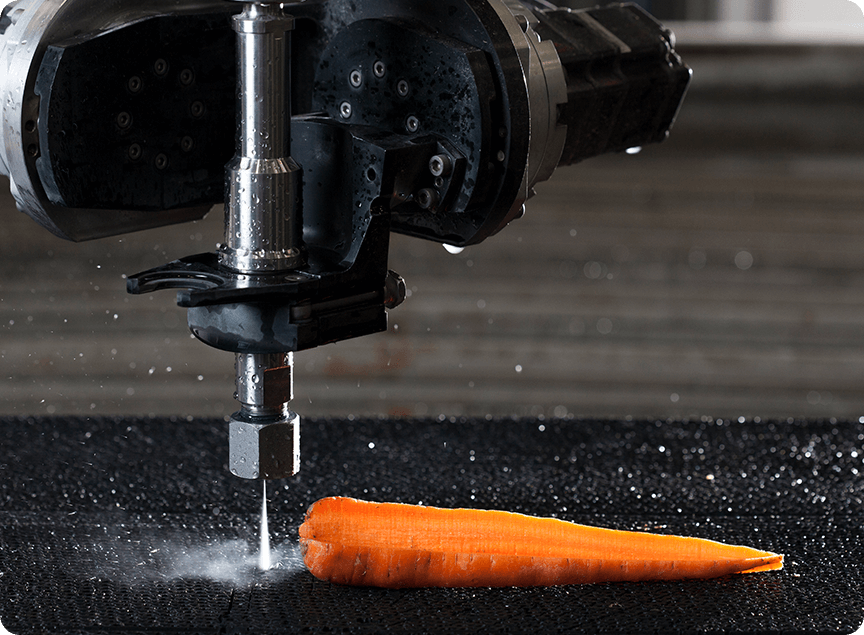

Waterjet is often regarded as the ideal cutting solution for job shops. A job shop rarely knows what project will come through the door next, and the ability of waterjet to cut virtually any material at any thickness on the same system, provides unparalleled flexibility for owners. A waterjet can support most any project that comes through the door, allowing owners to expand their business, take on more work, and provide a quick return on investment.

Waterjet's Perfect Match: Job Shops & Contract Cutting

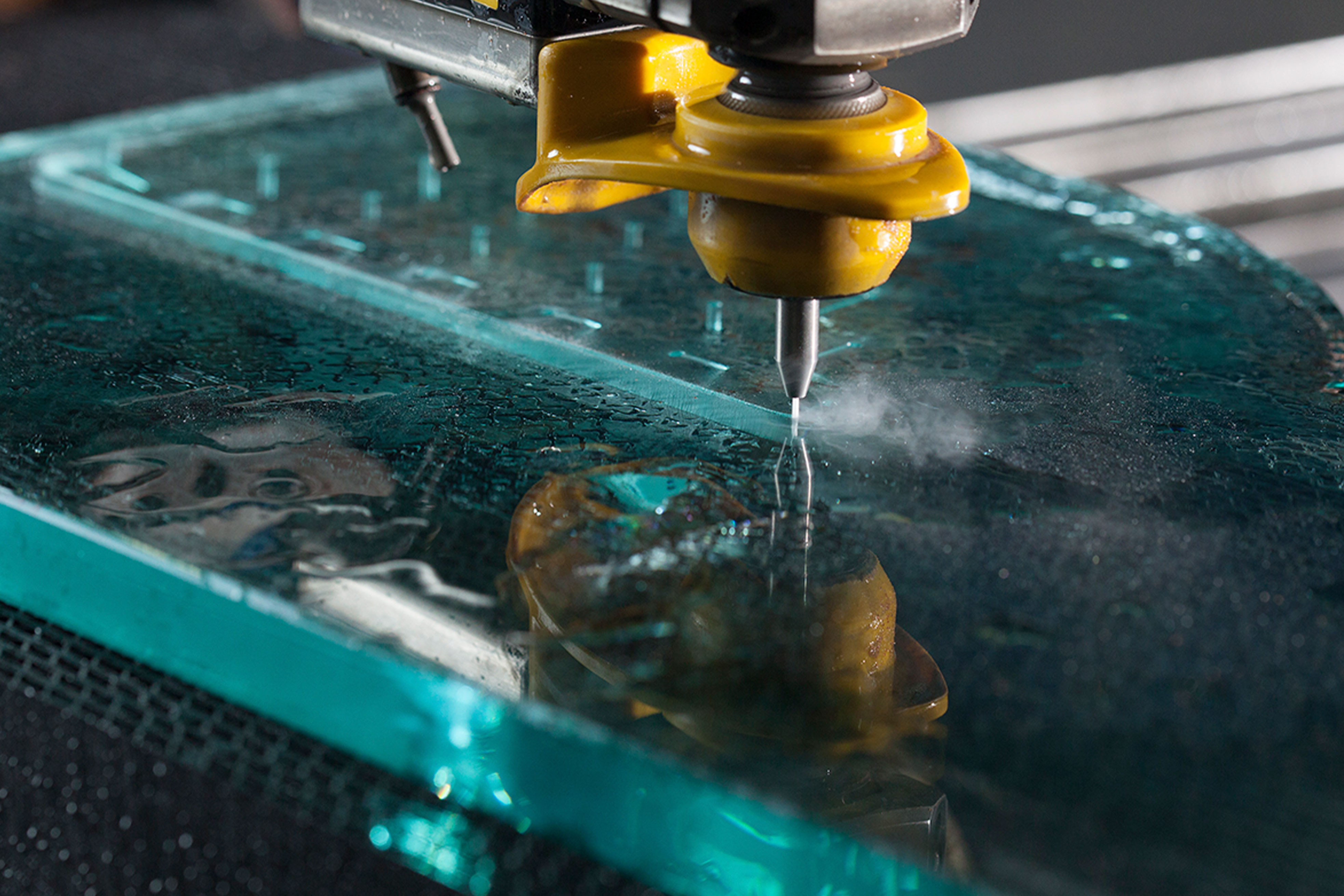

A major benefit to waterjet is that it is a cold cutting process. When it comes to metals, this means no heat affected zone (HAZ), slag, or dross to remove via secondary finishing. It also means you can cut rubber, foam, and gaskets, as well as glass, composites, and more, all with minimal system adjustments. There is virtually no limit to the type of material and thickness that a waterjet can handle.

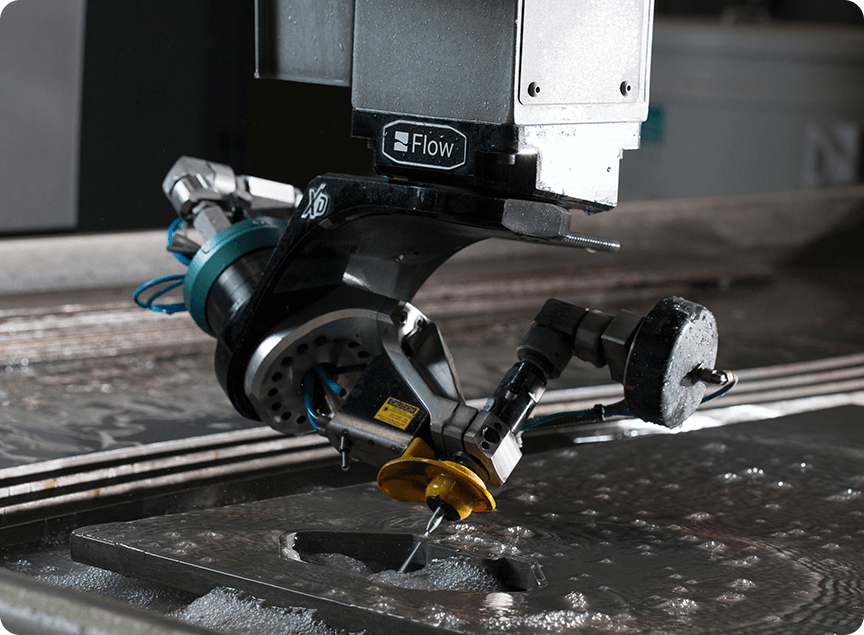

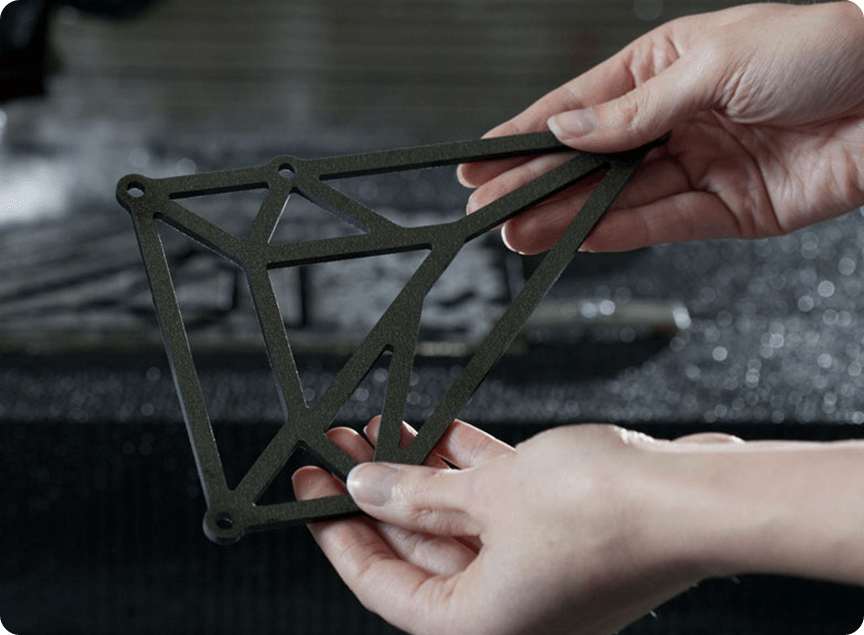

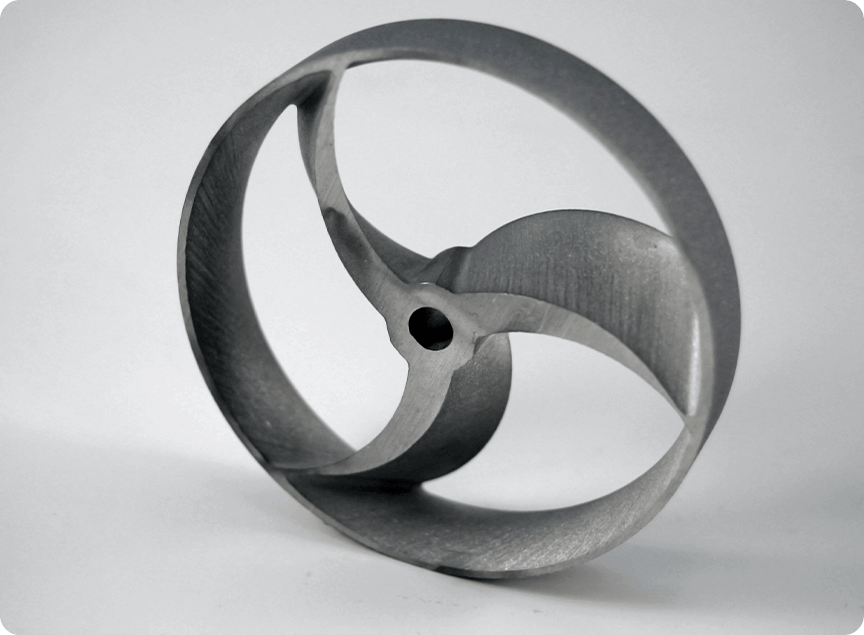

In addition to the ability to cut virtually any material, waterjets also allow you to cut in 2D or 3D depending on your needs. Straight cuts, intricate curves, chamfered edges, and bevels, all with high accuracy.

Flow Waterjets Deliver:Ultimate flexibility • Wide variety of systems to match your needs • Virtually no secondary finishing required • High production • Low maintenance

Versatile Machine Tool

Job shops often refer to the waterjet as the swiss army knife of machines tools because it does it all.

Cold Cutting Process

Cut Virtually Any Material

Intricate Cutting or Rough Cutting

2D Cutting, Bevel Cutting, and 3D Cutting

Popular Waterjet for Job Shops

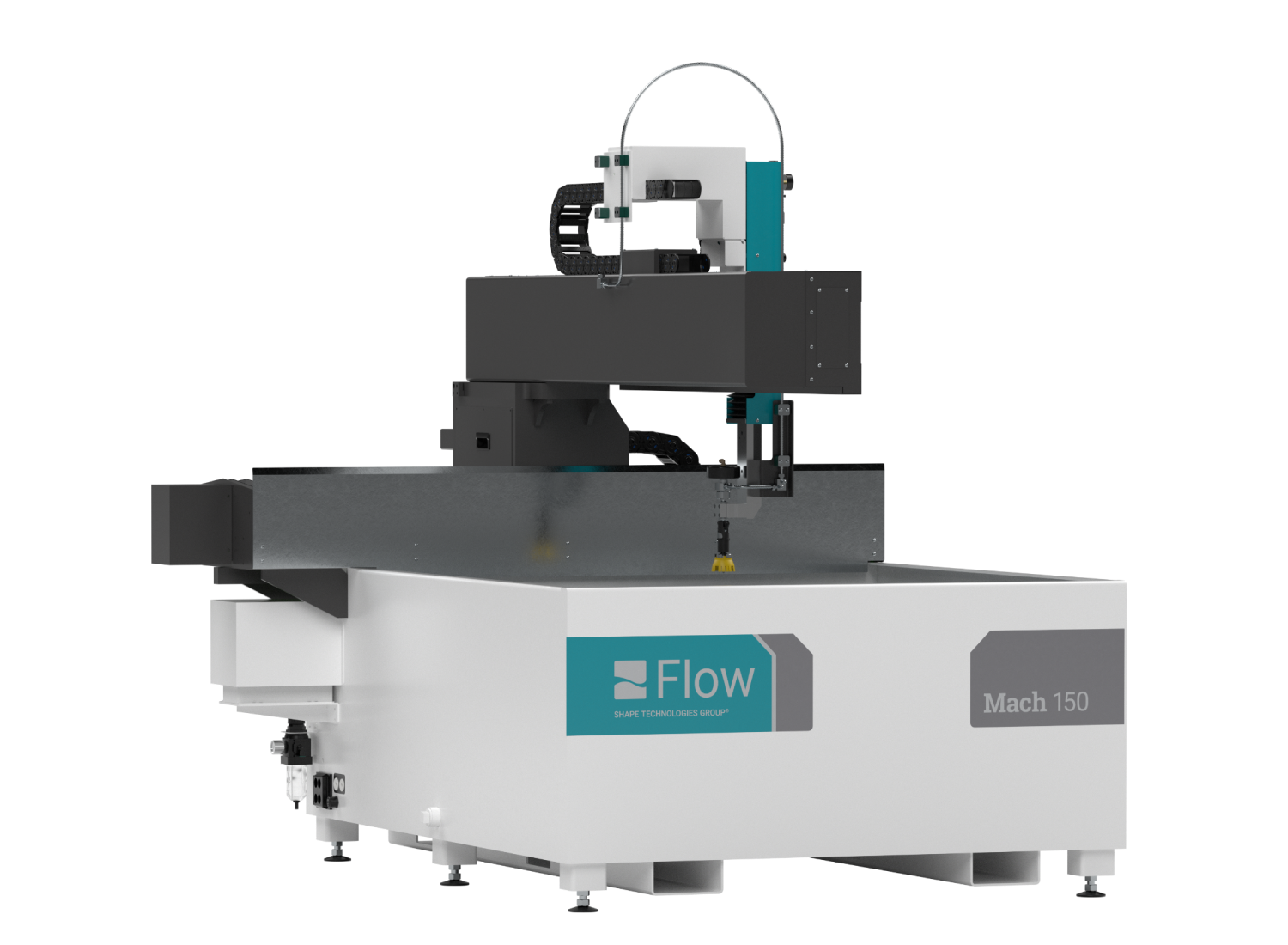

Mach 150

The Mach 150 is a value-focused solution, offering the fundamental versatility of waterjet cutting with no frills. Engineered with the same components as Flow's premium cutting solutions, the Mach 150 features robust cutting capabilities and a programmable Z-axis for added flexibility.

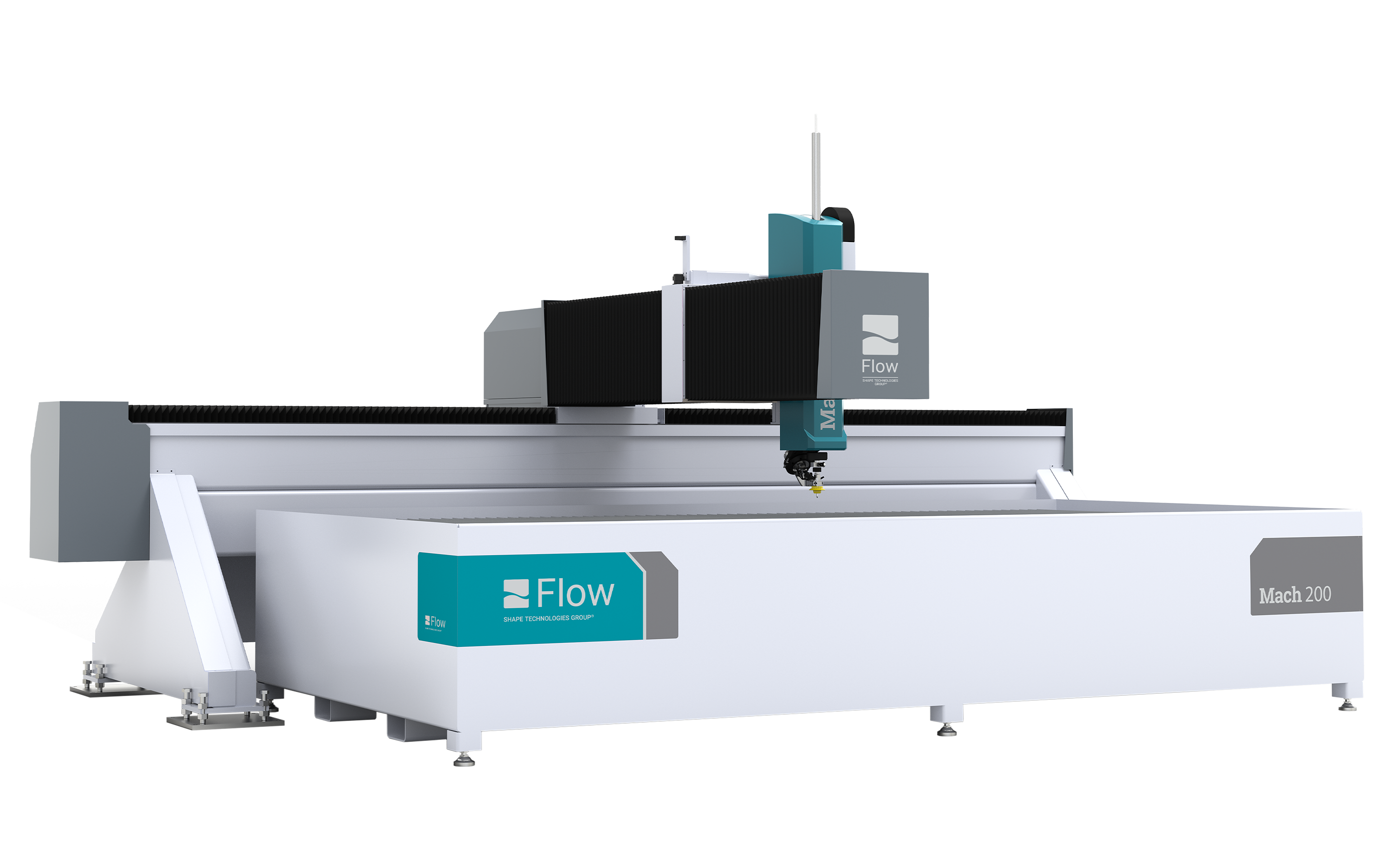

Mach 200

The Mach 200 is specifically engineered to deliver value, reliability, and performance. The system is purposefully crafted to be a practical and flexible waterjet solution, featuring tried and true genuine Flow technology.

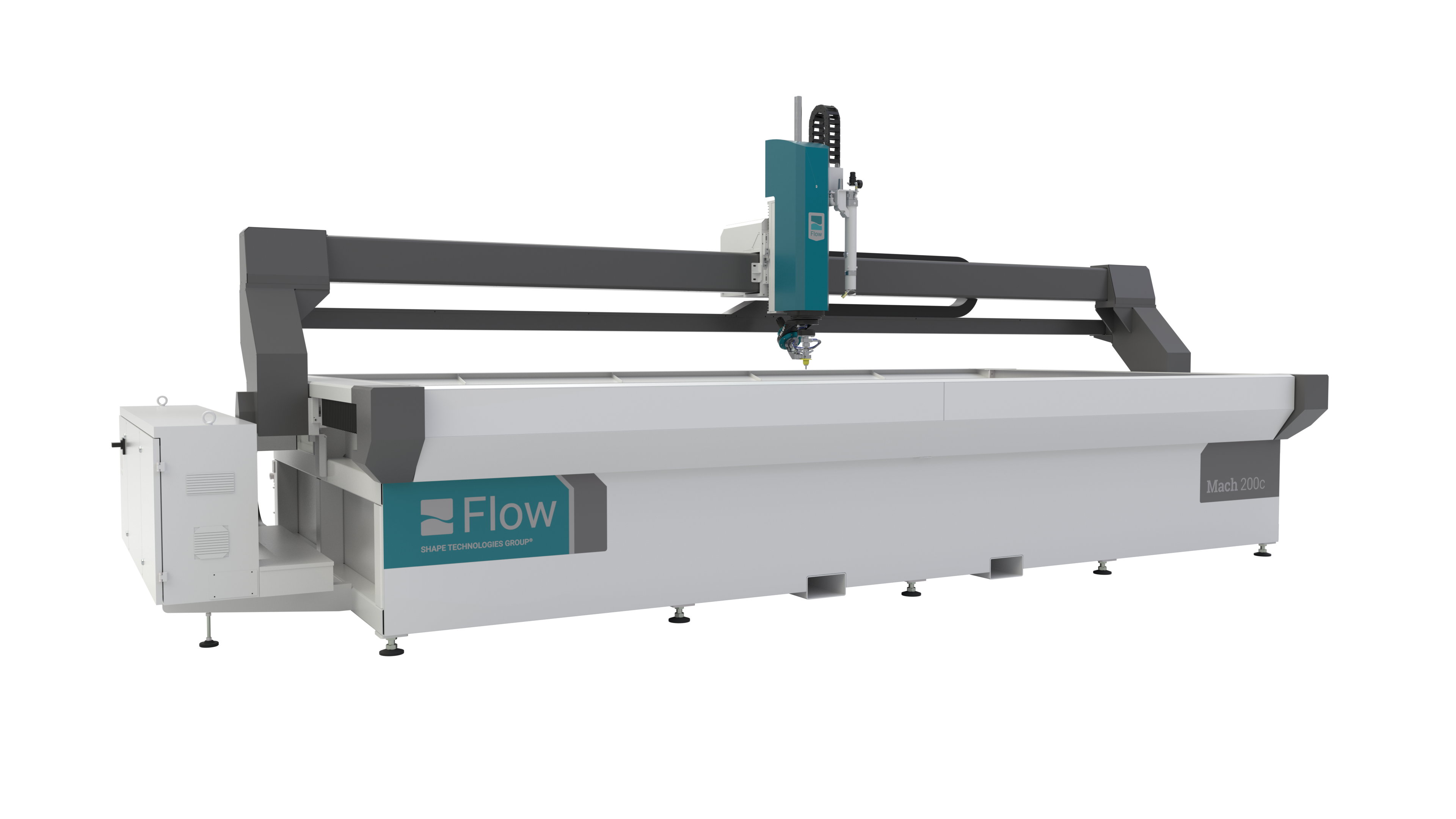

Mach 200c

The Mach 200c is a one-of-a-kind solution that offers maximum workspace and flexibility for 2D or 3D cutting. Its canted bridge design allows for full work envelope usage and sets it apart from standard open gantry solutions. Despite its value-focused approach, the Mach 200c boasts capabilities typically found in elite systems, making it a perfect mix of value and capability.

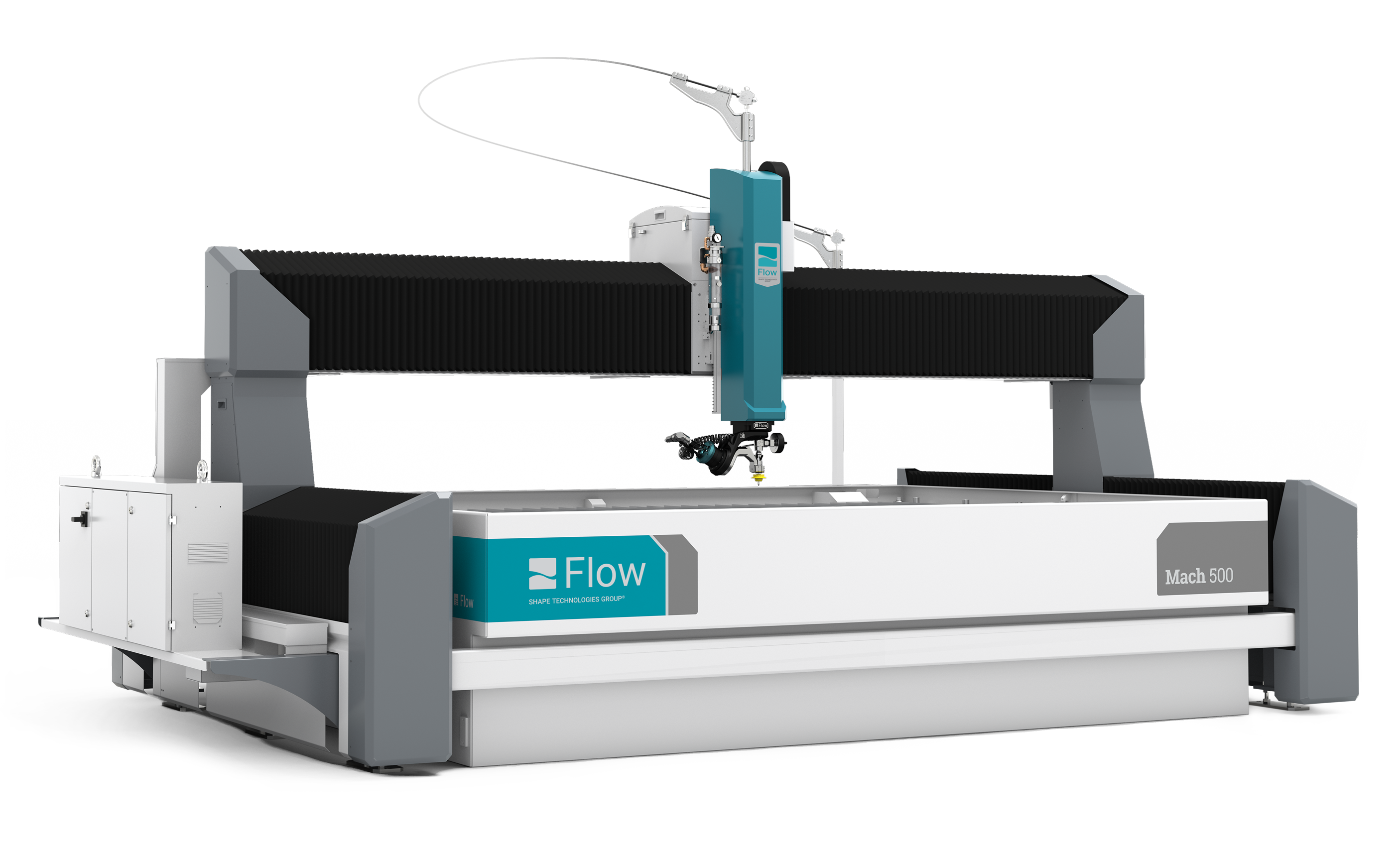

Mach 500

The Mach 500 is the workhorse of waterjet and comes with the widest configurability and options. Select from every Flow waterjet pump or cutting head option to gear your waterjet up for your specific machine shop needs.