Bevel Cutting with Waterjet

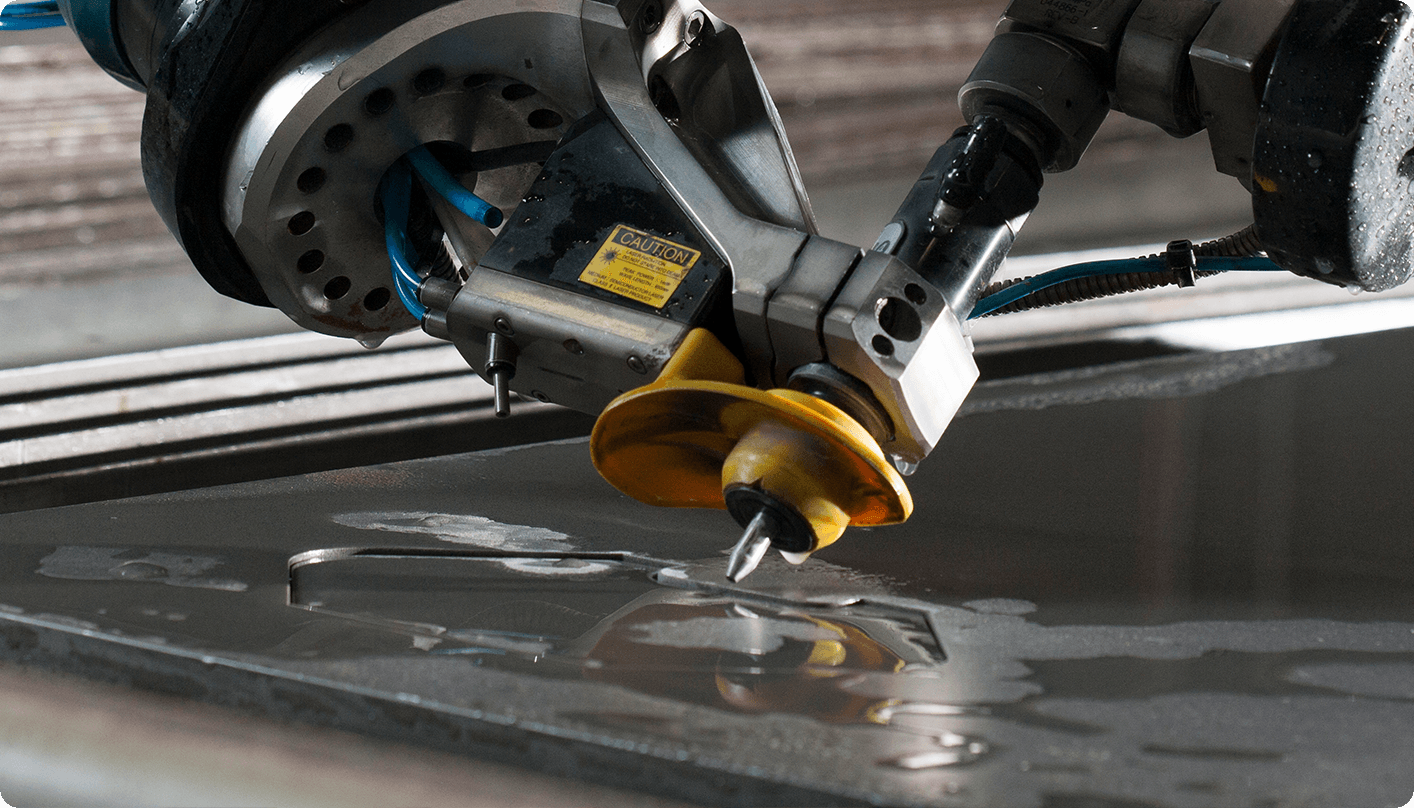

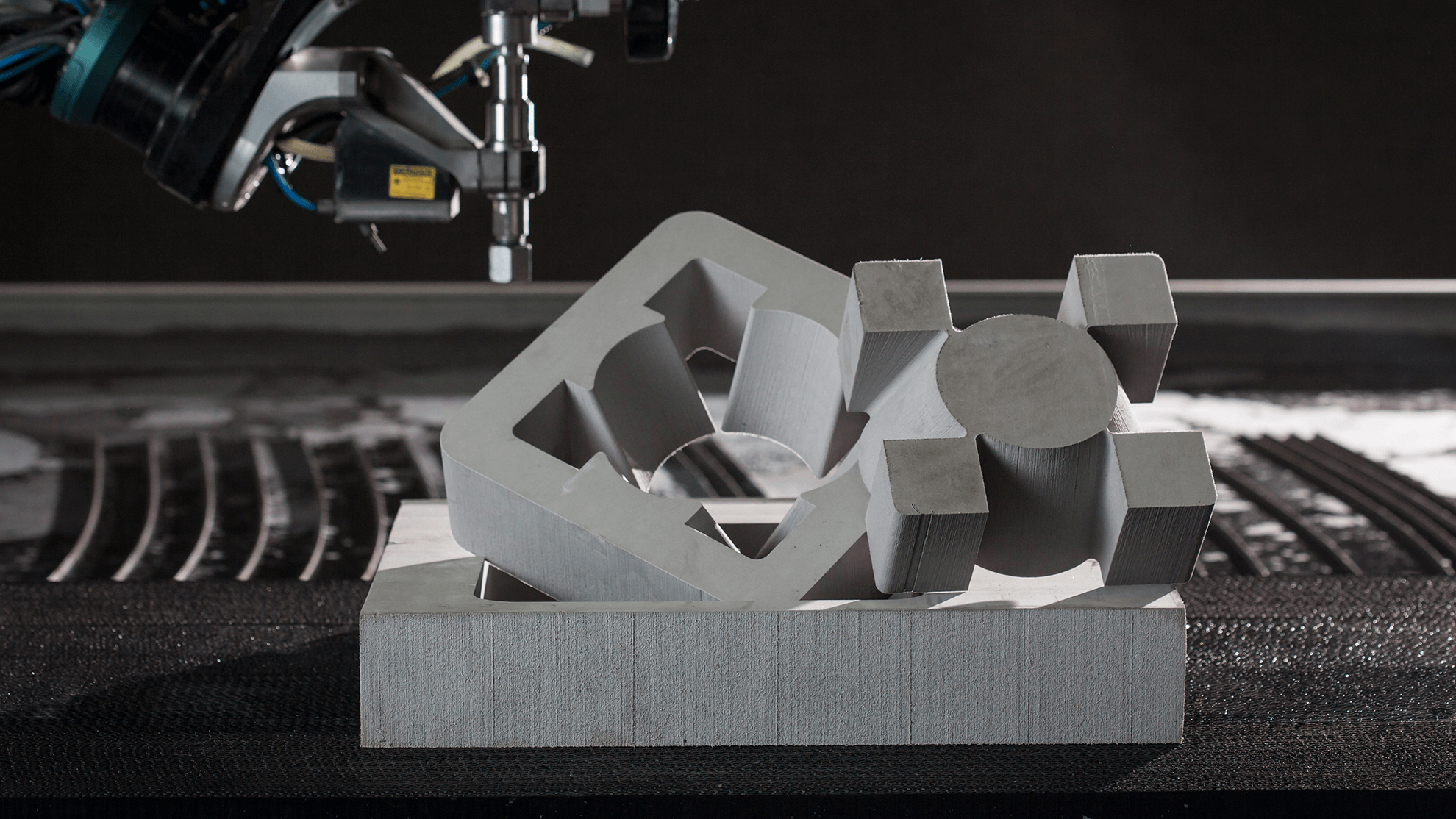

With today's advanced waterjet cutting system, complex shapes can easily be achieved. Bevel and 3D cutting of parts is made possible by technology invented by Flow, Dynamic XD, which articulates the cutting head up to 60 degrees for full flat stock bevel cutting capabilities.Not sure a waterjet can handle your material?

The Best Edge

Bevel cutting with Flow technology provides a higher quality cut part directly off of the cutting table, which can result in eliminating secondary processing.

Minimal Kerfs

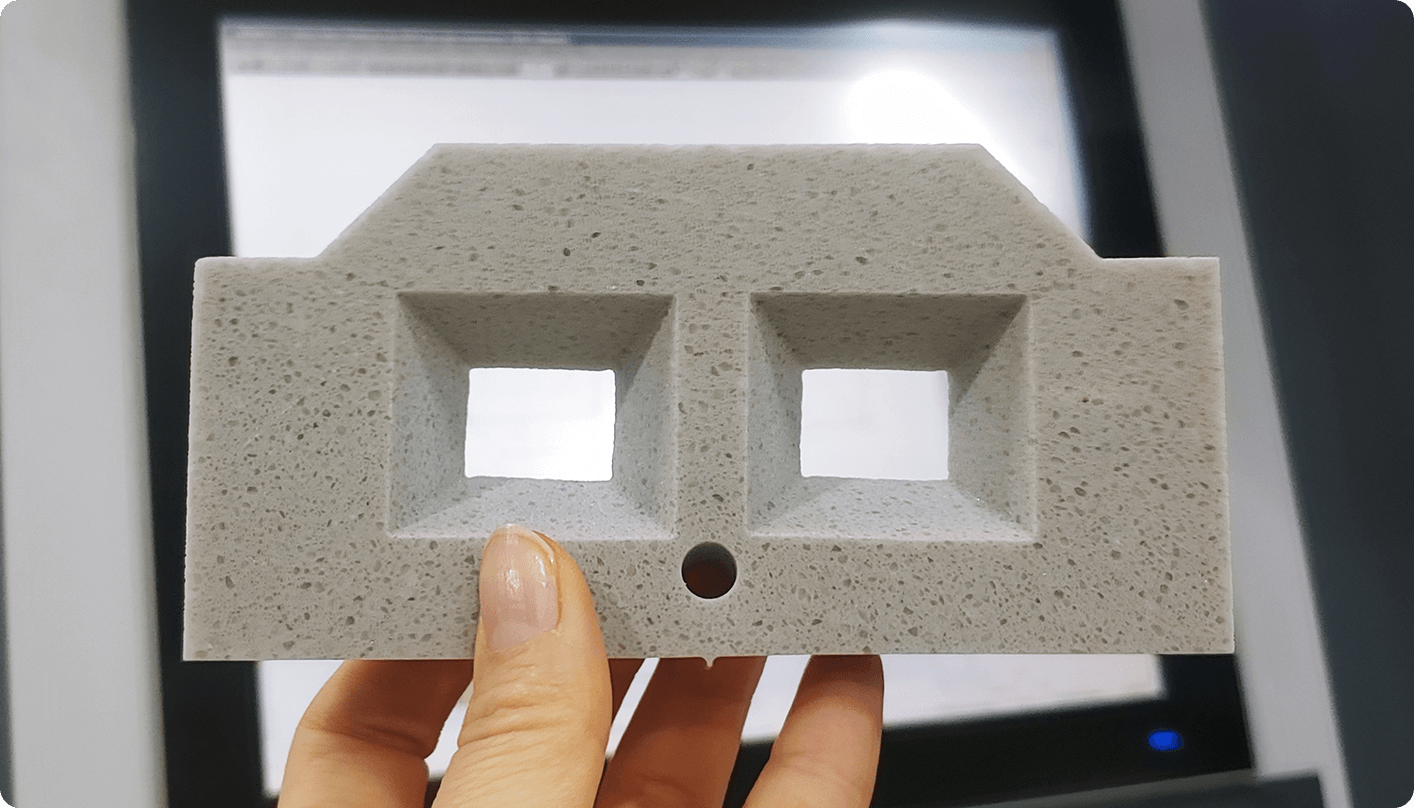

A key benefit to waterjet cutting is the minimal kerfs created due to the cutting process. The narrow kerfs allow complex parts to be tightly nested and cut to the highest accuracies.

Key Benefits of Bevel Cutting with Waterjet

- Increased productivity, fast cutting and high-quality parts

- Minimal kerf allows incredible detail

- Inconsistent material is not a problem (no need for expensive 'laser ready' material)

- Raw material savings — reduced scrap

- No need for extensive part clamping, minimal lateral or vertical forces

- Single-pass cutting, depending on material thickness

- No thermal damage

- Net or near-net cutting, little or no hand finishing