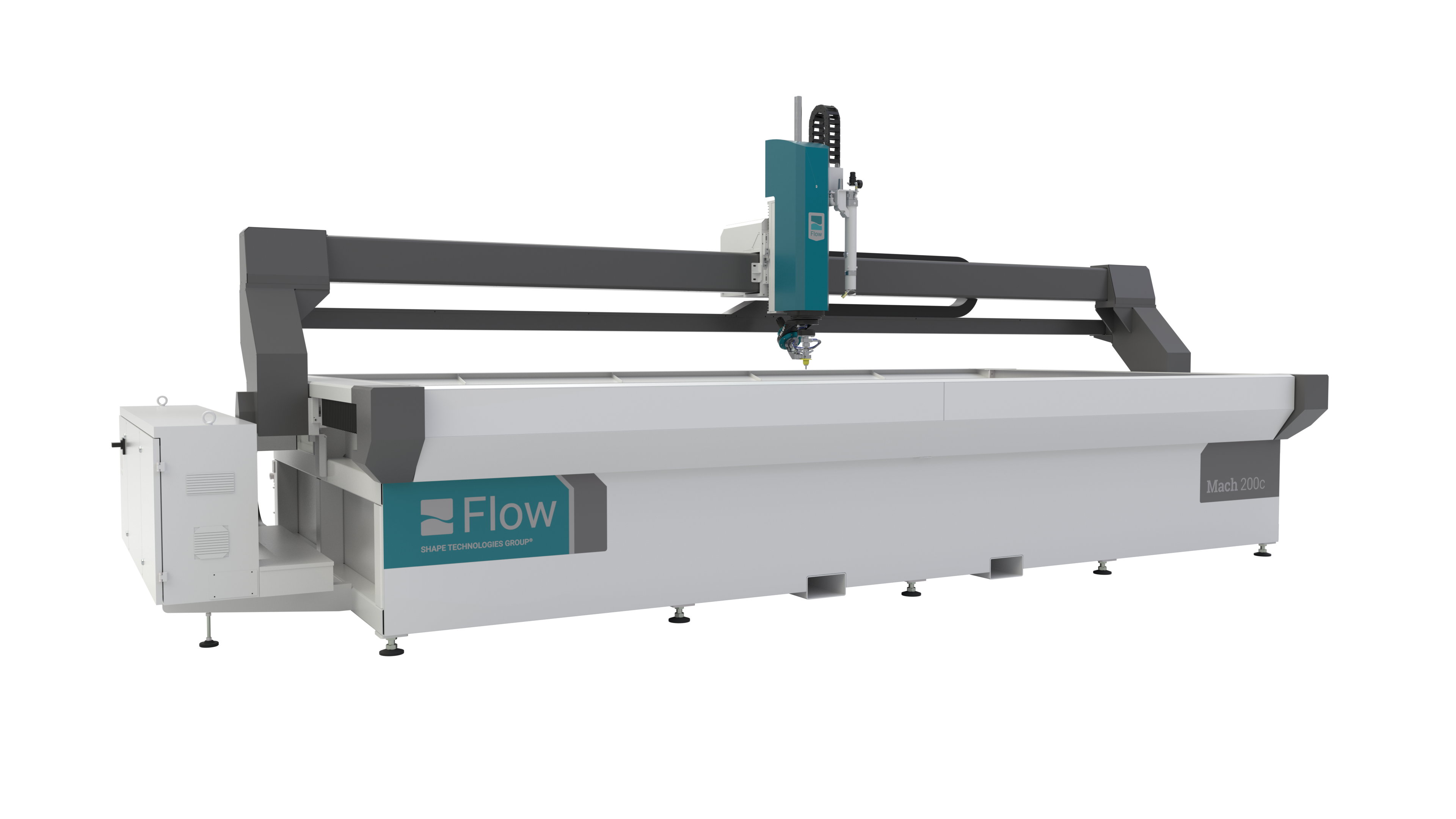

Mach 200c

All Access.

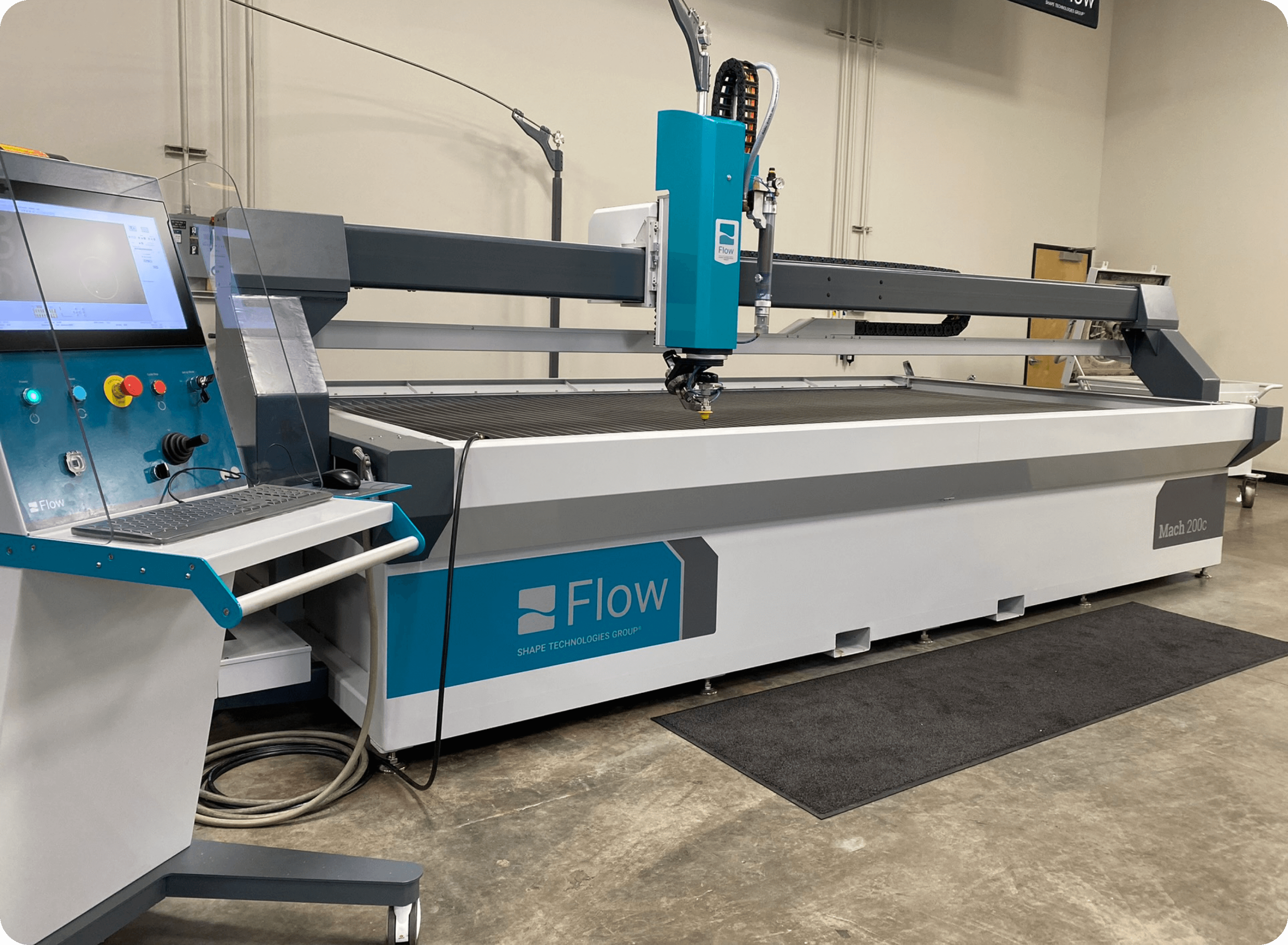

The Mach 200c is a one-of-a-kind solution that offers maximum workspace and flexibility for 2D or 3D cutting. Its canted bridge design allows for full work envelope usage and sets it apart from standard open gantry solutions. Despite its value-focused approach, the Mach 200c boasts capabilities typically found in elite systems, making it a perfect mix of value and capability. Multiple configurations make it the preferred option for fabricators, prototyping, and more.

Key Features

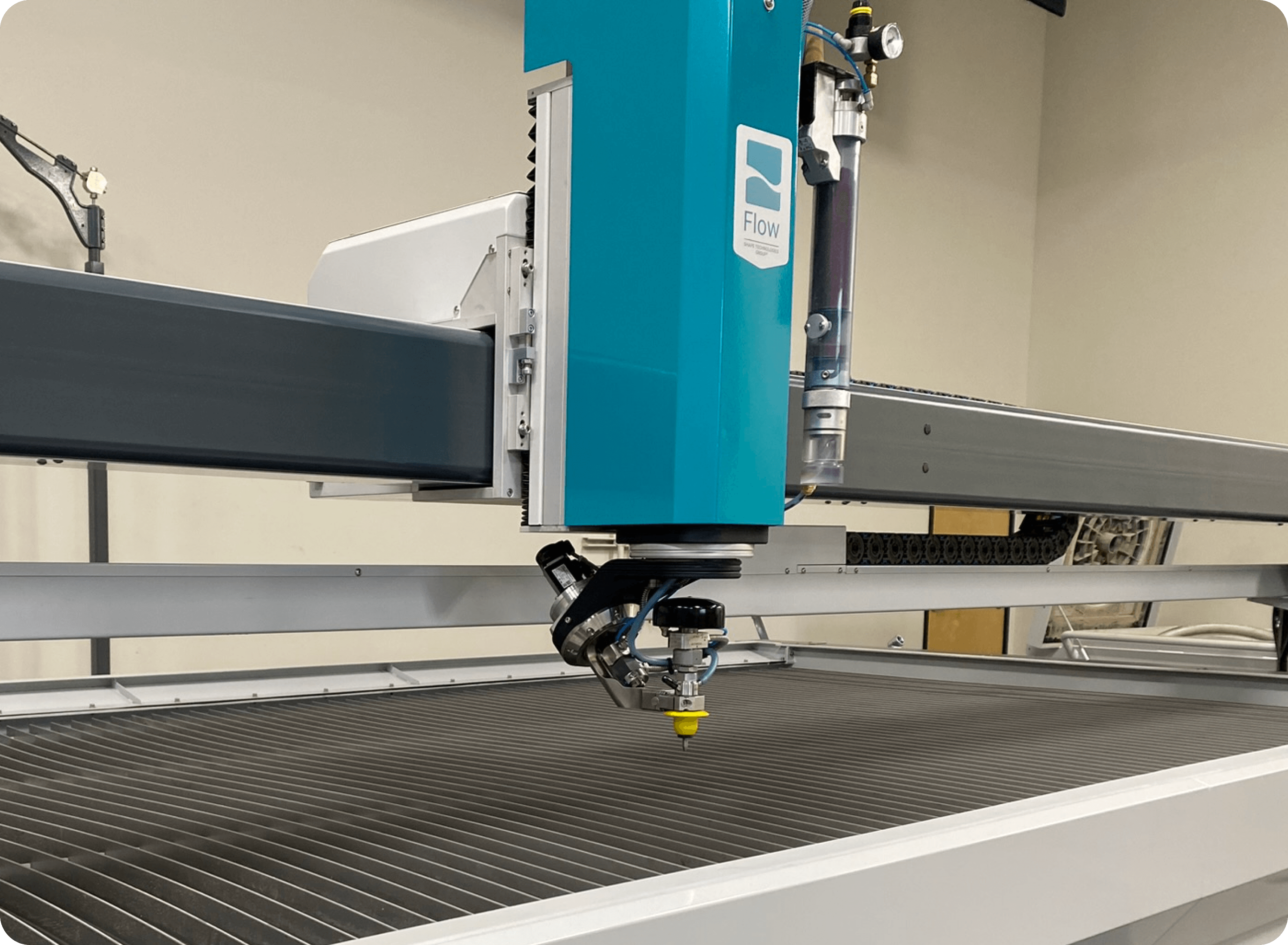

Beveling & 5-axis Capabilities

The Pivot+ Waterjet is a compact cutting head that uses a simplified, low-profile design to deliver 5-axis and bevel cutting capabilities with taper control.

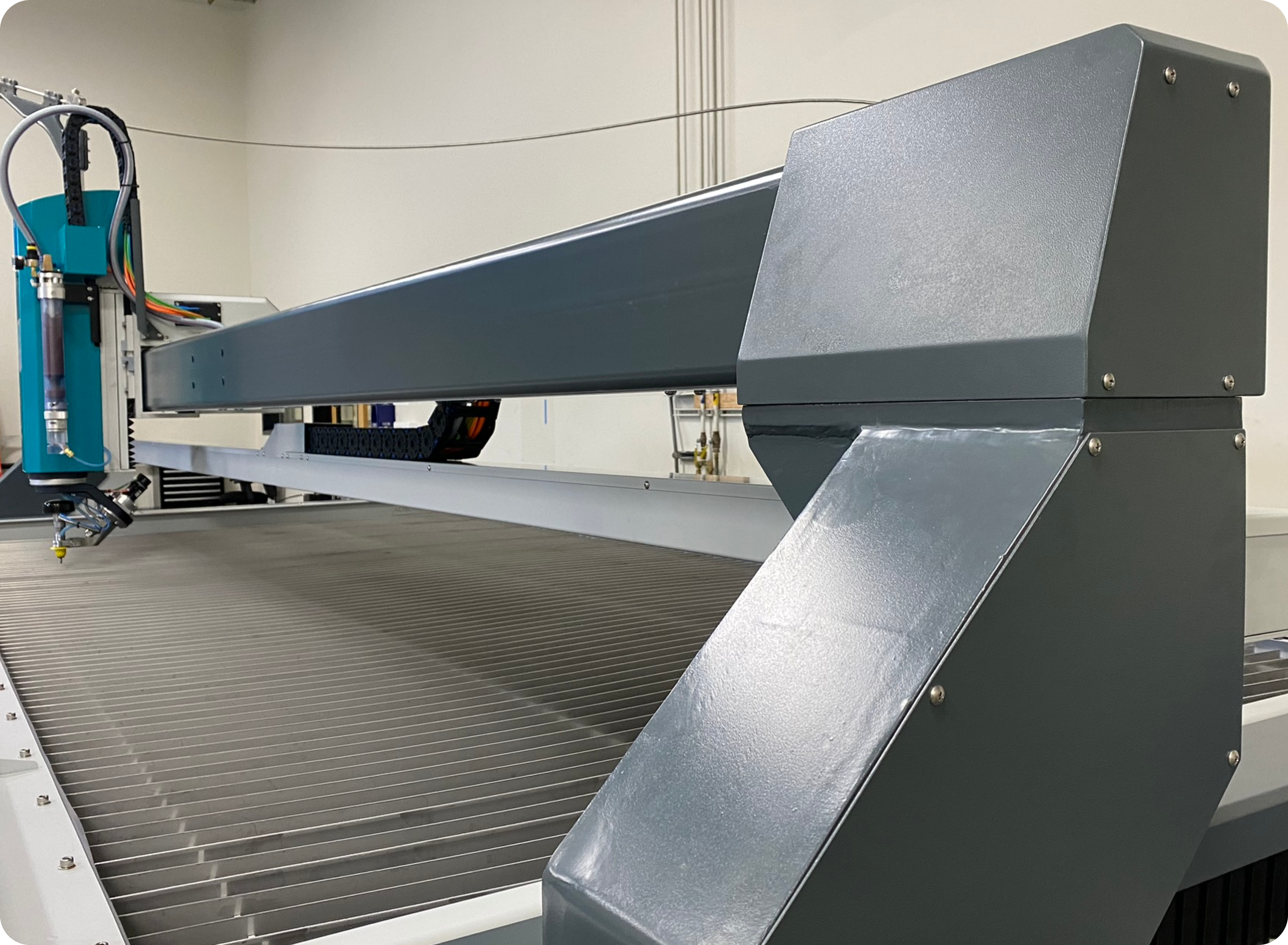

Full Work Envelope Usage

The unique canted bridge is designed differently than any other standard open gantry solutions, allowing for full work envelope usage.

Flexible & Versatile

The vast configurations and options of the Mach 200c make it a great match for fabricators, R&D, and more…and can easily adapt to application requirements.

High Speed, High Accuracy

High-speed motors and drives allow for rapid acceleration and deceleration, ultimately improving cut times while maintaining accuracy.

See the Mach 200c in Action

See what makes the Mach 200c our most flexible and value-packed machine yet.Mach 200c Series Sizes

General Specifications

Mach 200c 3020: 3.05 m x 2 m

Mach 200c 4020: 4 m x 2 m

Mach 200c 3020: 10' x 6'-6"

Mach 200c 4020: 13'-1" x 6'-6"

Core Component Options

Cutting Head Technology

Pure Waterjet

Hair-thin pure waterjet stream ideal for cutting soft materials.

Standard Waterjet

Uses garnet abrasive to cut virtually any hard material. Learn more.

Pivot+™ Waterjet

Pivot+ Waterjet for bevel cutting and taper compensation is a compact, 5-axis cutting solution designed for high-accuracy cutting. Learn more.

Dynamic Waterjet®

Three times faster and more accurate than Standard Waterjet. Learn more.

Pump Technology

HyPlex® Prime

60,000 psi [4,150 bar]

The highest pressure, most advanced direct drive pump available today, with pressures rated at 60,000 psi [4,150 bar]. Learn more.

MotoJet®

60,000 psi [4,150 bar]

With continuous operating pressure at 60,000 psi [4,150 bar], the MotoJet is built for the demands of high-production environments. Learn more.

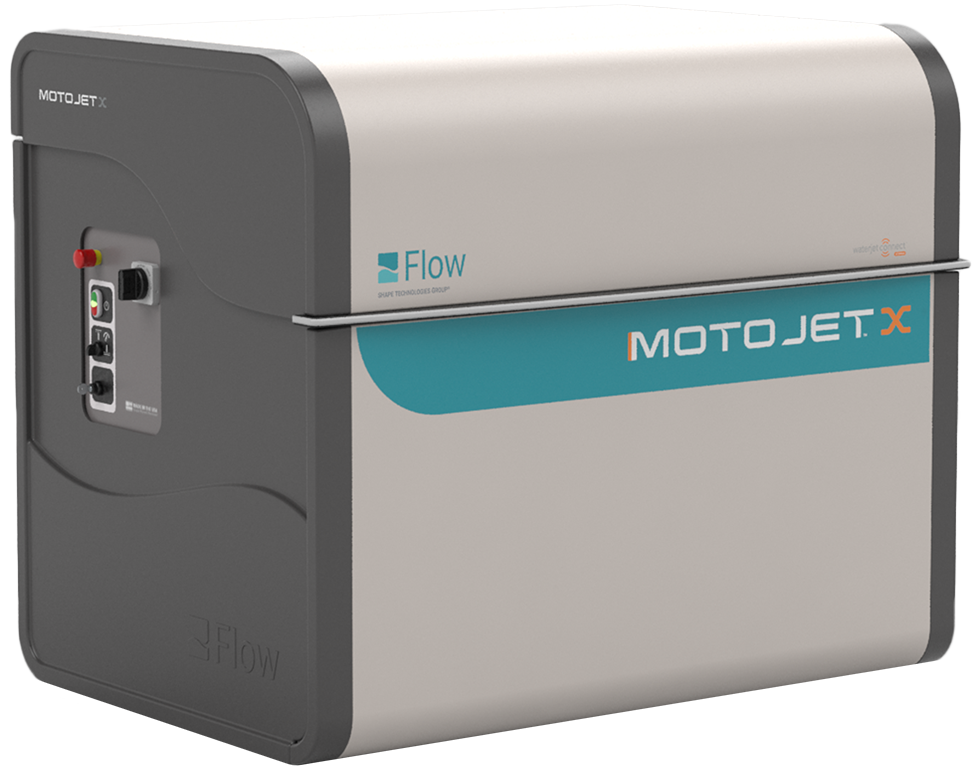

MotoJet® X

60,000 psi [4,150 bar]

Engineered to maximize uptime, minimize maintenance, and outlast and outperform the rest. It's the longest lasting pump in the industry. Learn more.

Software Suites

FlowMaster

The FlowMaster software suite, consisting of FlowCut, FlowPath, and FlowNest has everything you need to design and cut 2D waterjet parts. Learn more.

FlowXpert

The FlowXpert software suite, consisting of FlowXpert Infinity, FlowCut, and FlowNest gives you all the tools you need for both 2D and 3D cutting. Learn more.

Service Guarantee

We are committed to providing you with the tools you need to keep your system running at its best. Professional training is available in both classroom settings, as well as on-site.

Best for these Applications

You might also like…

Webinar

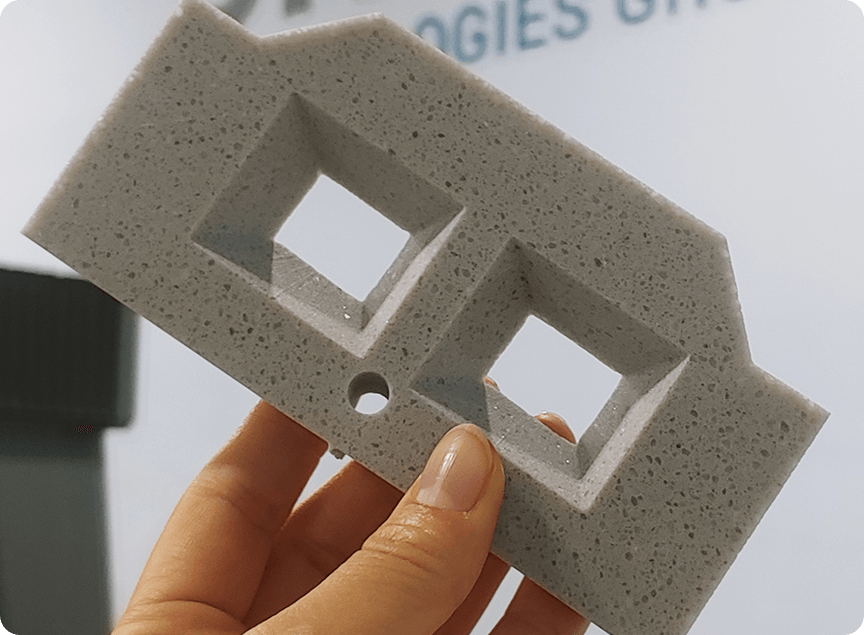

Spotlight On Stone

Have you ever wondered how a waterjet can make a difference in your stone fabrication operations? Waterjet easily cuts natural and engineered stone – both straight lines and curves – while reducing manual labor and costs.

Watch Now

Article

Overcoming Challenges of Stone Cutting with Waterjet

In a recent survey on home buying preferences, one out of every four respondents said they preferred a custom-built home rather than a new home already built or an existing home. But when your customer requests a unique design, you’re often faced with several challenges. Fortunately, there is a solution to working with difficult natural and man-made stone materials: waterjet cutting technology.

Read More

Article

Countertops and Beyond: Three Trends We’re Seeing in Engineered Stone

There are two types of pumps used today in waterjet cutting: the linear intensifier pump and the rotary direct drive pump. Today, both intensifier and direct drive pumps are successfully used in the industry.

Read More