Metal Service Centers

Maximize output with waterjets offering dual heads and large cutting envelopes

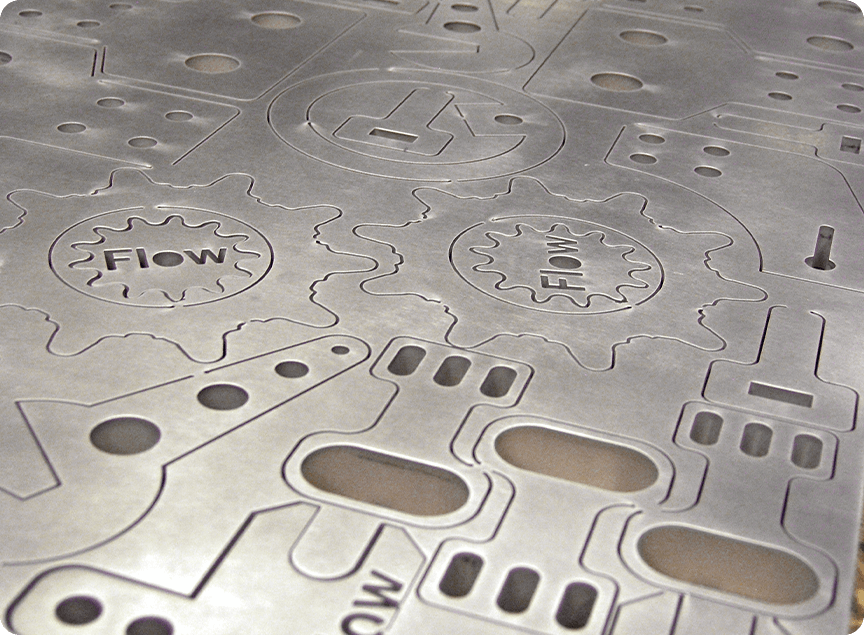

Metal service centers have a continual need to cut aluminum, steel, or other exotic metals in a wide variety of shapes, often as a value-added service for their end customers, providing more than just a metal plate. By using a waterjet to produce near-net shapes for their end-users, metal service centers differentiate themselves in the marketplace and provide unique competitive advantage, backed by value.

Large Waterjets, Large Production for Metal Service Centers

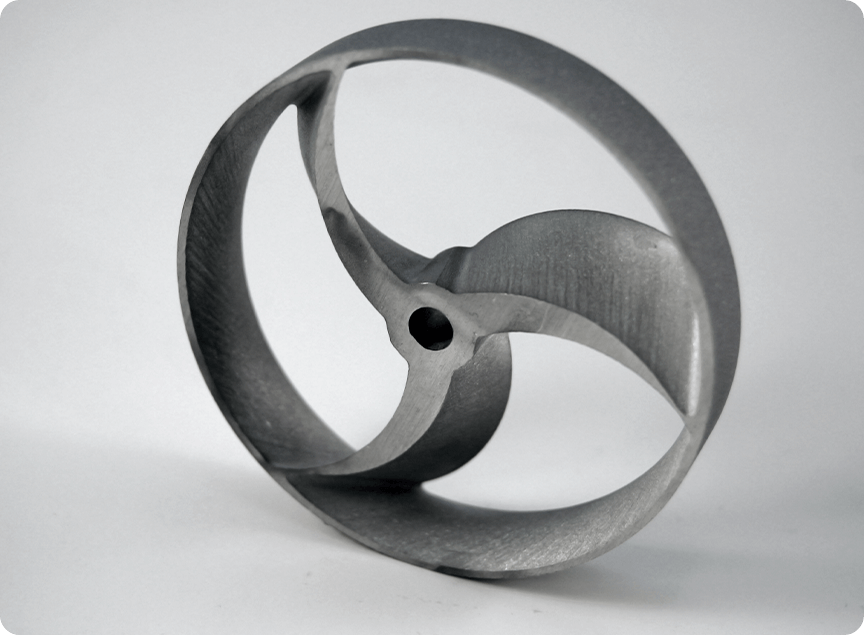

Whether cutting thin aluminum, thick titanium for aerospace, or other exotic metals and beyond – a large waterjet table size matched with cutting heads that deliver flexible capabilities and Flow’s exclusive ultrahigh-pressure cutting technology provides metal service centers with the ability to take on nearly any customer request that comes through the door.

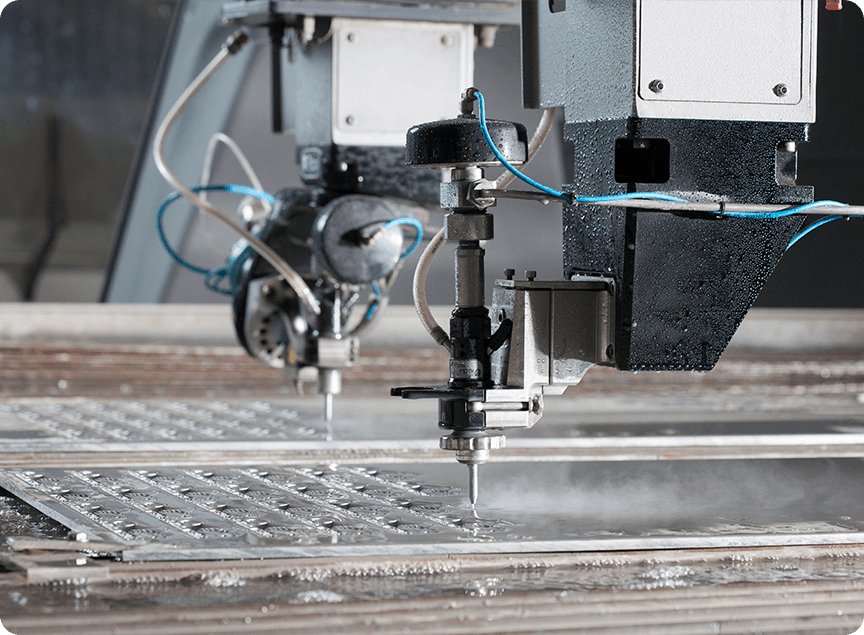

It’s common for metal service centers to process large, heavy, thick material that can beat up poorly built waterjet cutting systems.

Flow Waterjets Deliver:

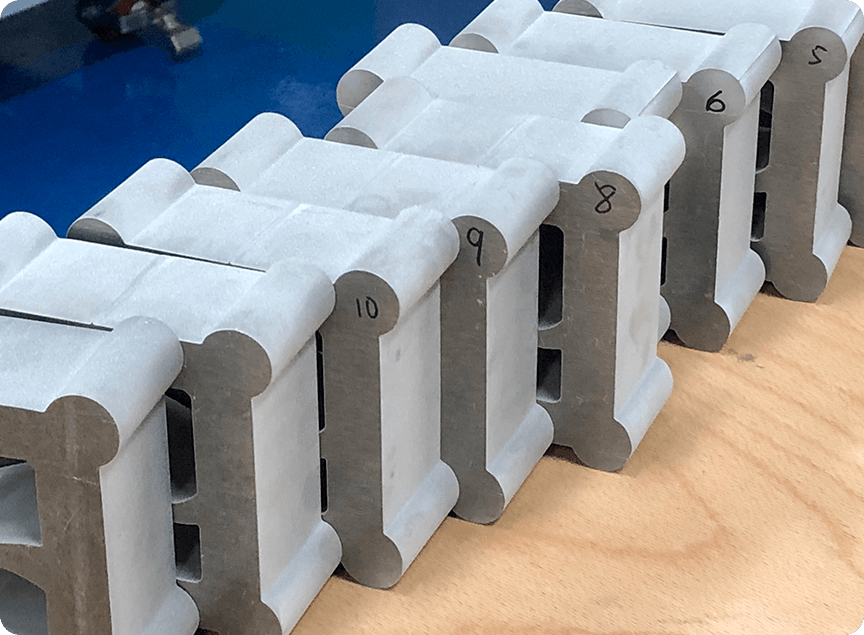

Ultimate flexibility • Compact or Large Dual Head Systems • 3D capabilities • 24/7 production • Virtually no secondary finishing required

Why Waterjets Are Good For Metal Service Centers

Flow waterjets are engineered and built to operate in tough environments, run on a 24/7 production schedule, and reliably deliver consistent parts day in and day out.

Thick or Thin Cutting

Tight Kerf, High Material Utilization

Large Cutting Beds

Dual Zone Cutting

Popular Waterjets for Metal Service Centers

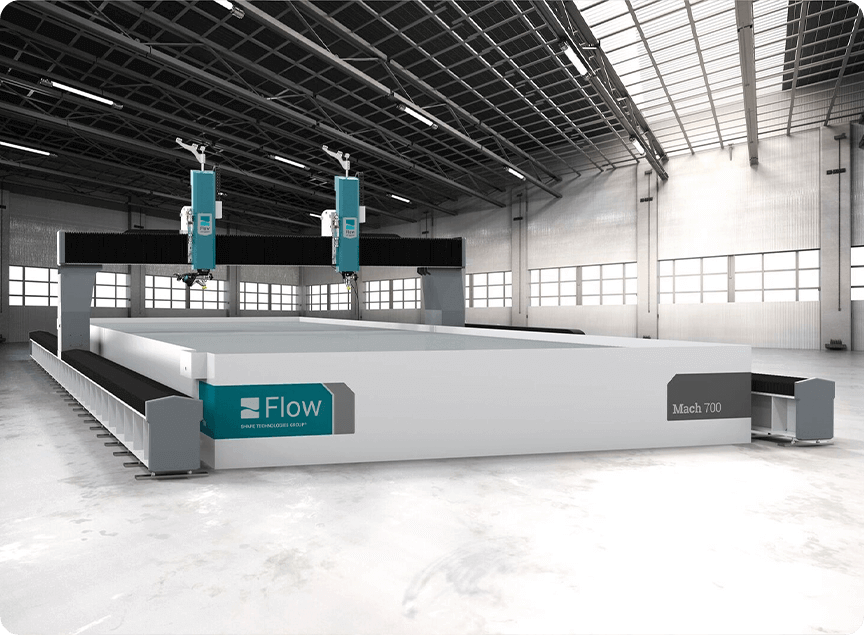

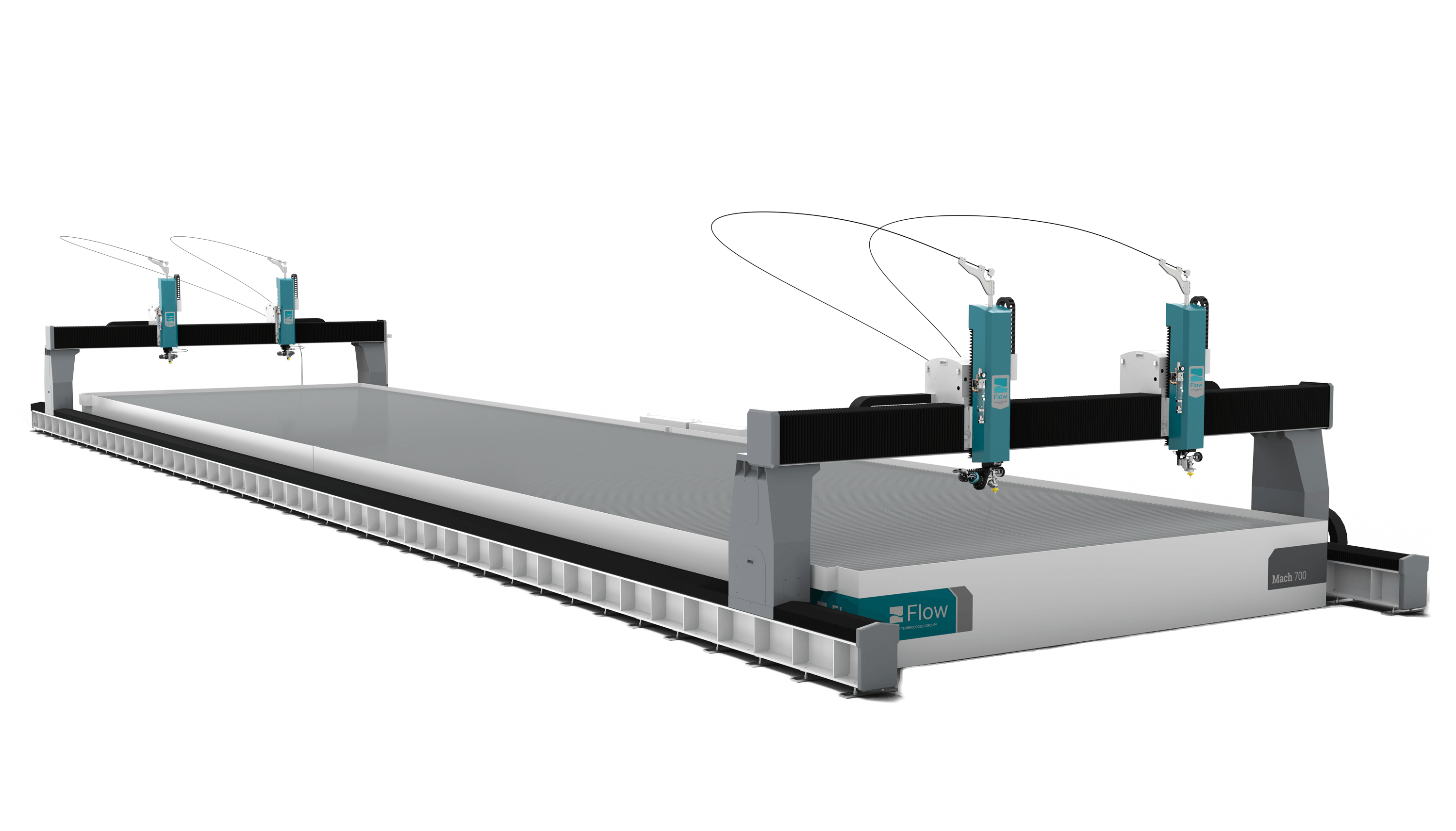

Mach 700

The Mach 700 is the ideal solution for heavy industry, with options for dual bridges, dual and cutting zones. The Mach 700 is a large format waterjet engineered for high production environments.

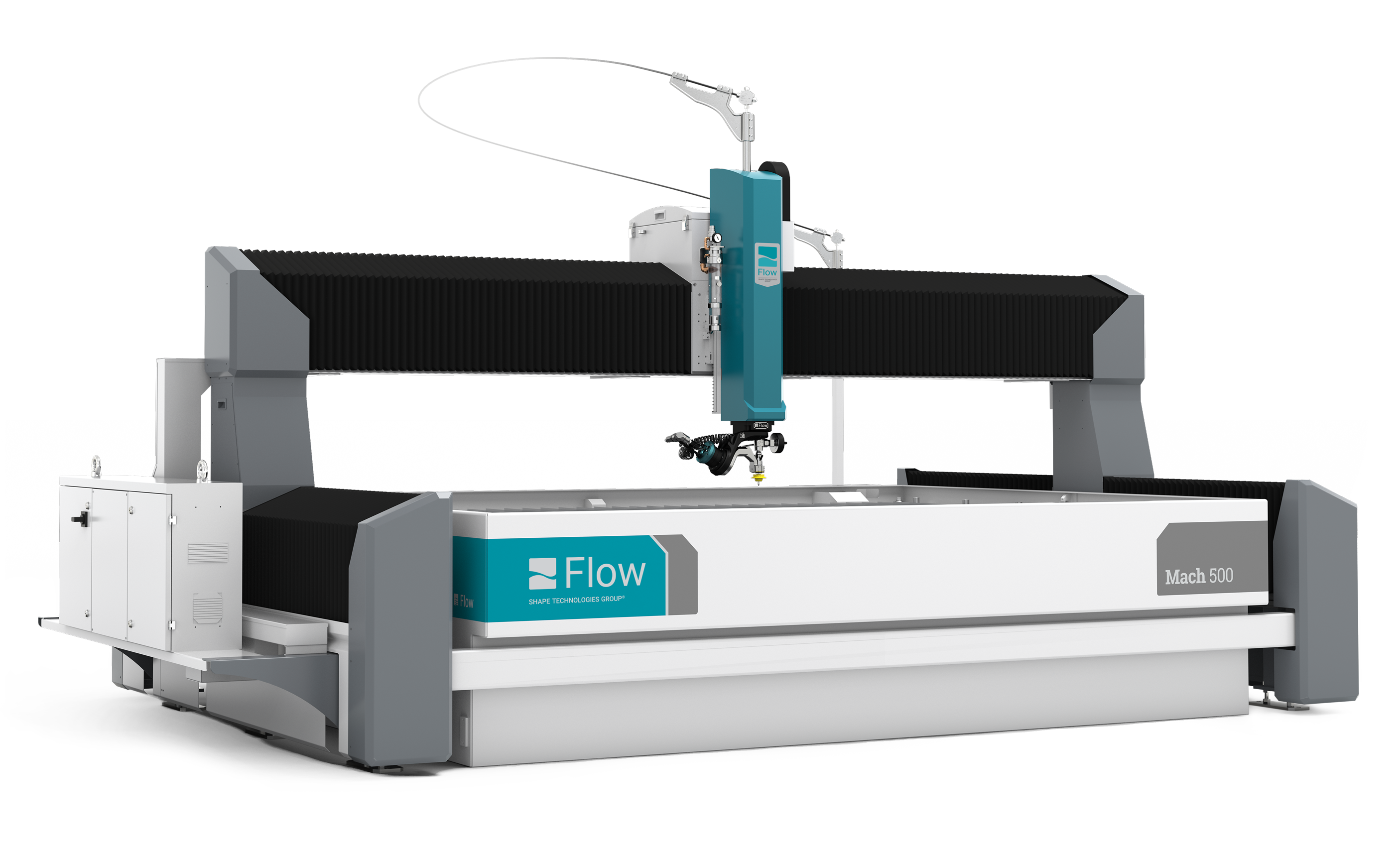

Mach 500

The Mach 500 is the workhorse of waterjet and comes with the widest configurability and options. Select from every Flow waterjet pump or cutting head option to gear your waterjet up for your specific machine shop needs.

EchoJet

This enclosed waterjet solution is well-suited for a machine shop. From the compact model to larger solutions, the EchoJet keeps the waterjet behind closed doors, with added operational efficiencies.