Contract Cutting From a Different Angle

Lynn Welding had specific requirements when it came to their material cutting. As one of the most well-known welding companies for the aerospace, defense, nuclear, industrial, and medical industries, many of their projects required accuracy and minimal warping. They found what they needed in waterjet technology.

Intelligent Cutting Solutions

As the number of projects grew, along with their business, outsourcing waterjet work to different job shops was no longer the best option. Instead of simply bringing the waterjet in-house, though, Lynn Welding’s Vice President, Darius Kania and Operations Manager, Ibrahim Ibrahim decided to turn it into an entirely new business model, with waterjet at the forefront.

Kania and Ibrahim founded Lynn Welding’s sister company Intelligent Cutting Solutions (ICS), a waterjet contracting company. The opening of ICS not only allows the support of Lynn’s business needs but opens the doors to support the waterjet needs they observed to be lacking in their region.

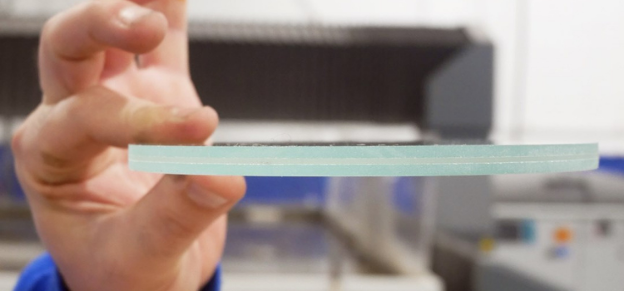

Although most of ICS’s customers are in aerospace—due to the work they do for Lynn Welding—they service a multitude of industries from automotive, to submarines, to architectural work, including stone and tile applications. “In general, we don’t like to stick with one niche, we like to branch out to cover all bases with whatever we can do.” said Rick Comeau, Waterjet Operator and Drafter for ICS, speaking to the versatility of waterjet technology.

A testament to their success, ICS installed their fourth waterjet within two years of opening their business. They are currently cutting with two Mach 500 4030s with Dynamic Waterjet® XD and HyperJet pumps, a Mach 300 3015 with Dynamic Waterjet and HyperJet pump, with the addition of their fourth, a Mach 300 2015 with Dynamic Waterjet, and a 60K intensifier. With at least two or three of their waterjets running for a minimum of ten hours a day, every day, adding the fourth waterjet will only help ICS grow. “Having that open capacity and customers knowing they’re going to get that turnaround time. They’re not going to get that anywhere else. That’s the big thing for us there,” said Comeau. “Waterjet makes it a little easier to schedule. Bringing the additional machines have helped with turnaround time and minimize downtime. It gives us the capacity to do the maintenance. It helps with our turnaround which in turn makes the customers happy and make them come back.”

The waterjet’s versatility gives ICS cutting capabilities they can’t achieve with other methods. From a marketing standpoint, having the ability to cut virtually any material opens the door to many different industries of potential customers. “We’re not restricted to one specific industry and can cut one specific material into one specific pattern or shape,” said Alexia Marchetti, Marketing Manager for ICS, “Because it is so versatile, we can pretty much target ourselves to anybody.”

The waterjet is only one piece of ICS’ success. As a dedicated contract cutting company, they take pride in the relationships they’ve built with their customers. As one of the few waterjet companies whose focus is strictly contract cutting, they can prioritize customer orders, and minimize lead times. ICS also prides themselves in their process which includes being in constant communication with their customers from the start of the project to delivering the final product. “We’ve only been open for two years. I would never have expected to already have four machines,” said Comeu. “I knew it was in the plan, but how quickly we’ve grown … it’s due to the quality of work, our response, our communication. I wouldn’t be surprised in say, five years, we’re moving out of this building into something bigger.”