Pressure Matters

Waterjets cut with a supersonic waterjet stream. The only way to make a waterjet stream go faster is to raise pressure. As pressure goes up, the stream velocity increases, delivering greater cutting power density. What is cutting power density?The Waterjet Pump

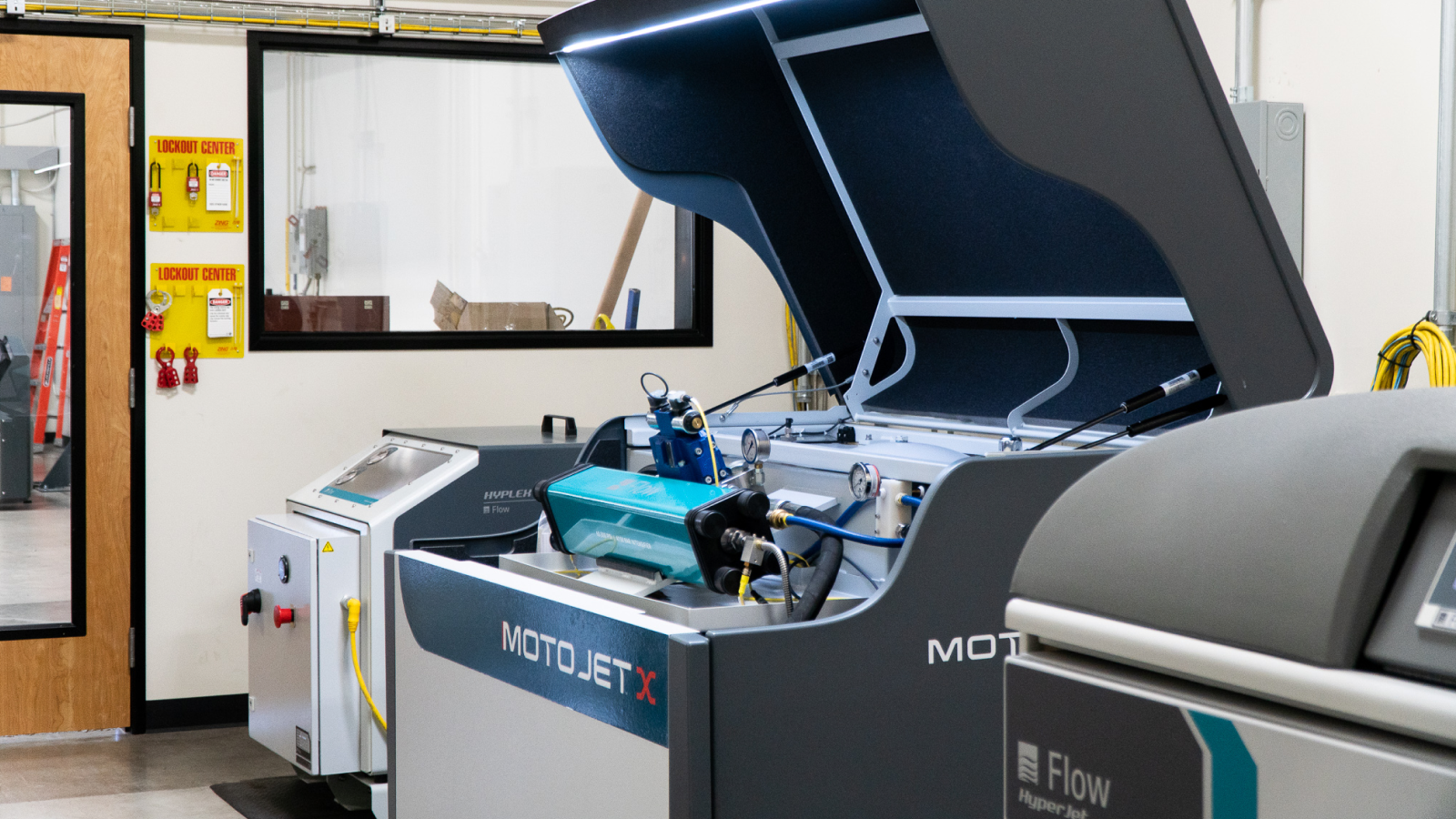

The waterjet pump is at the heart of it.

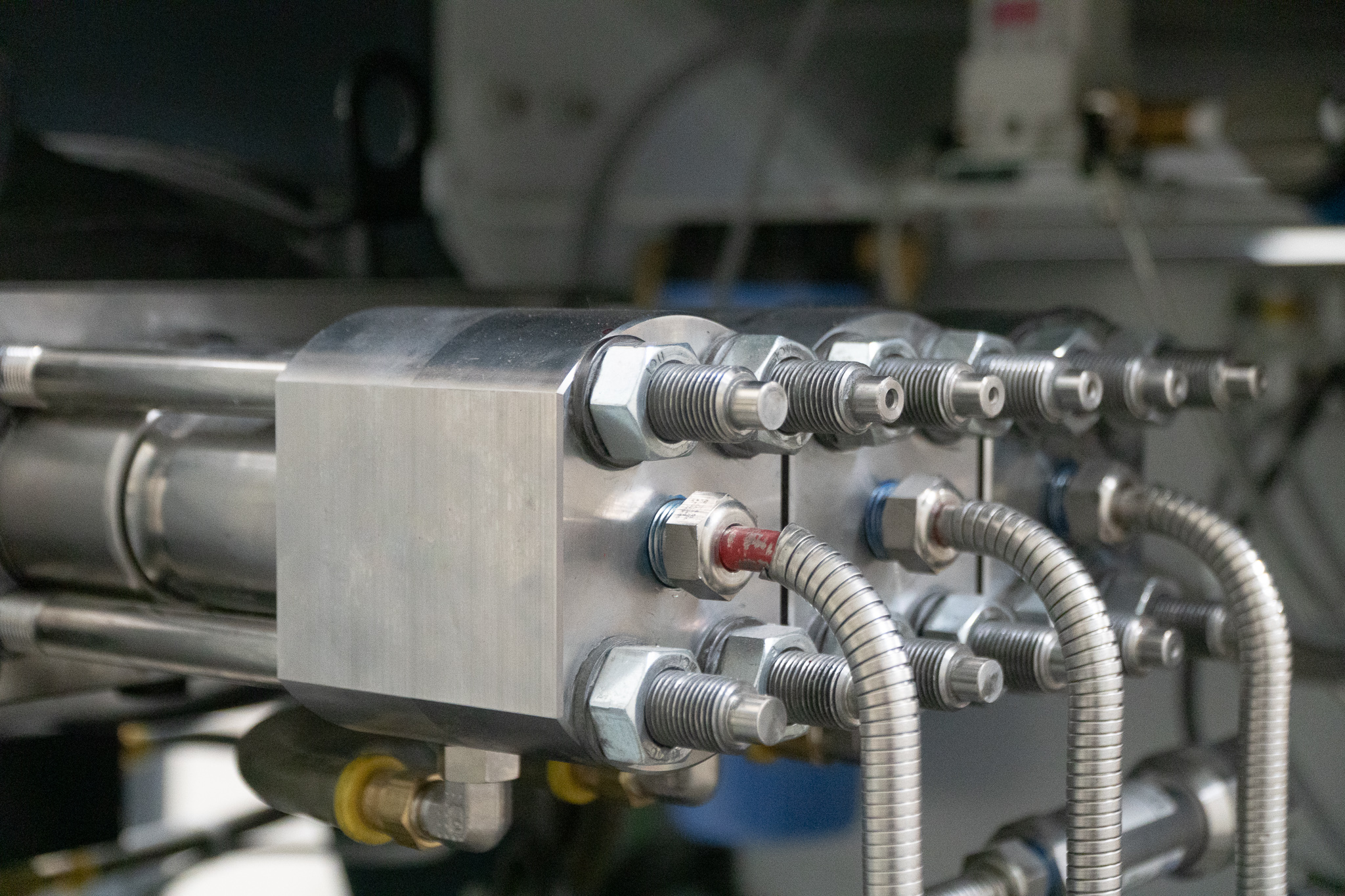

The pump is the heart of the waterjet system, pressurizing water so that it can be continuously delivered to the cutting head – and turned into a supersonic waterjet stream.

HyperPressure™

Increasing pressure significantly increases waterjet productivity.

Cut Faster

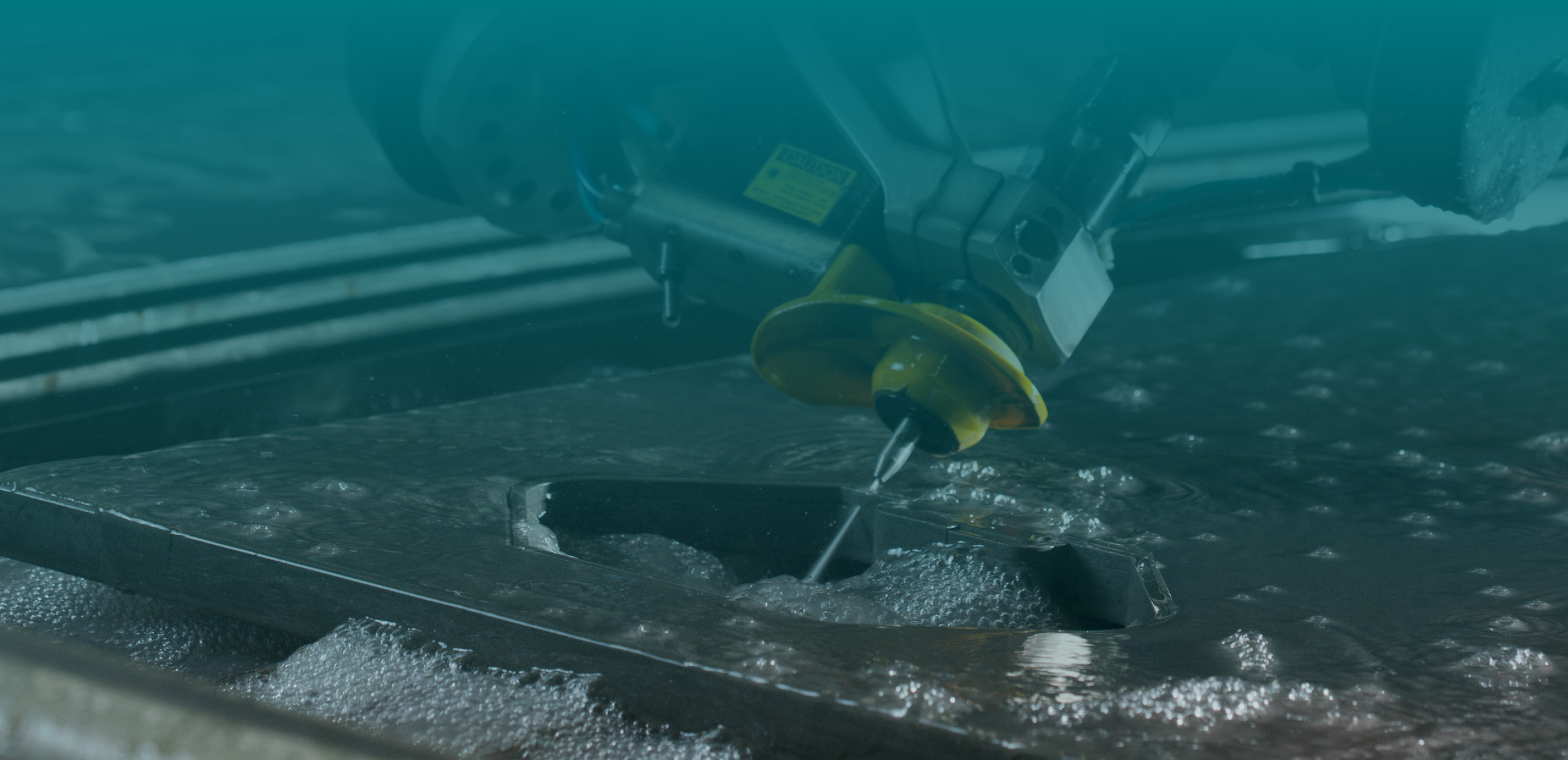

Regardless of material or thicknesses, cutting speeds increase with higher pressure when the cutting head parameters are held constant.

Increase Productivity

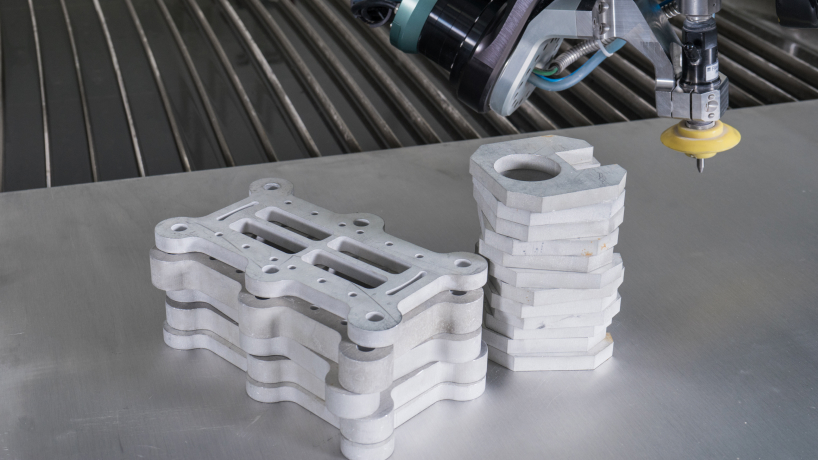

From stone to aluminum, steel to exotic composites, increases of 30-50% in cutting speeds are a result of accelerating the abrasive waterjet stream to the fastest level available.

Get Results

Faster cutting speeds mean more parts can be cut and throughput for any shop will increase. From in-house production to custom fabrication and contract manufacturing shops, more jobs can be completed in less time.

Stream Velocity

Waterjets cut with stream velocity.

How do you get velocity? With ultrahigh-pressure water.Ordinary tap water is filtered and fed into a waterjet pump rated to pressures of 60,000 to 94,000 psi (~4100 to 6400 bar). The pressurized water runs to the cutting head safely contained within the plumbing to maintain pressure. At the cutting head, the water to pass through the jewel orifice and the supersonic waterjet stream is created.

All the pressure is exchanged for velocity when the water passes out of the jewel orifice. The higher the pressure, the higher the stream velocity.