Machine Shops

Amp up Precision, Production, and Versatility

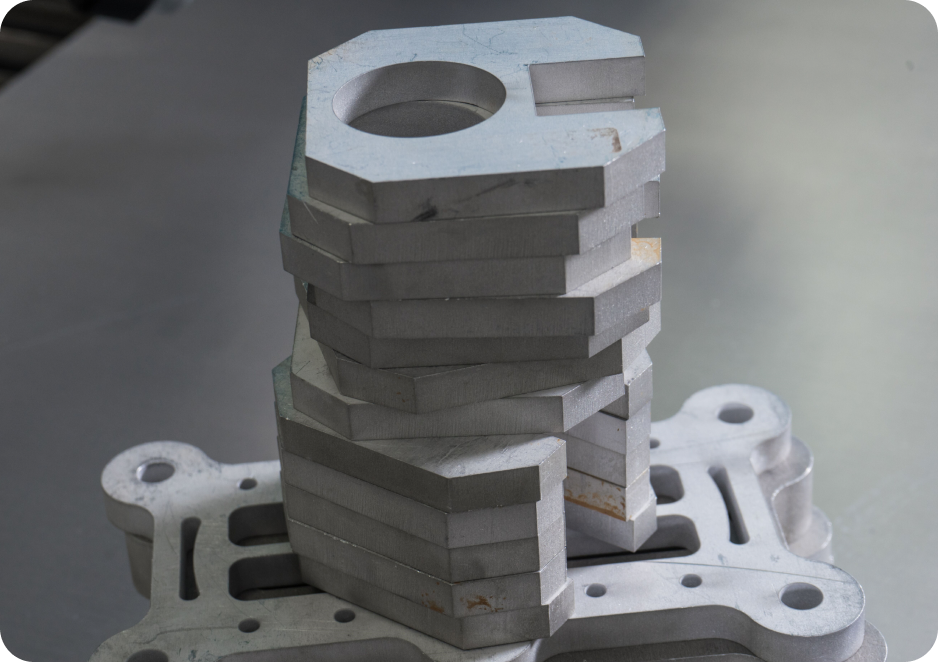

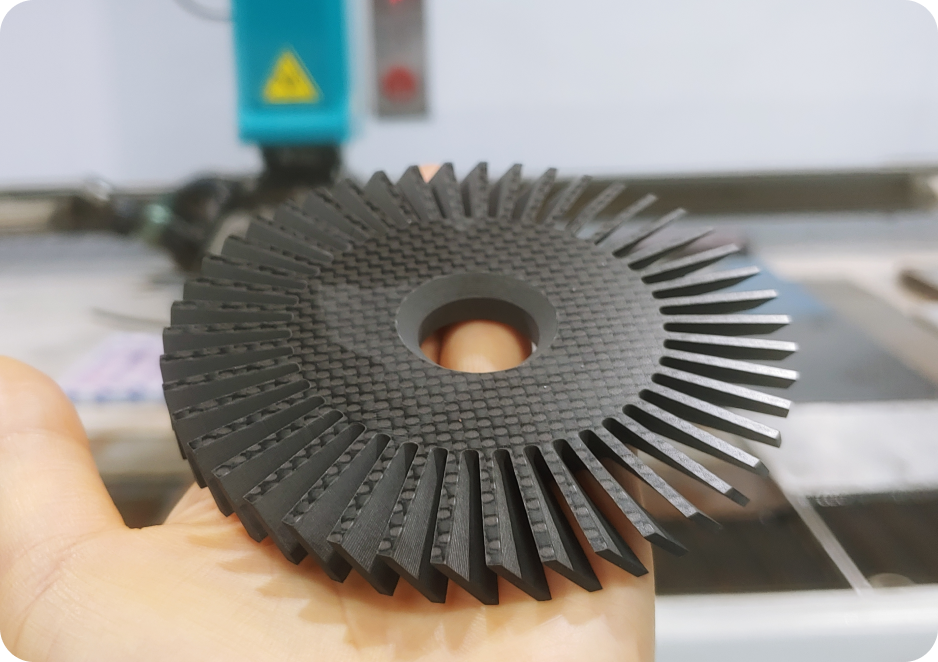

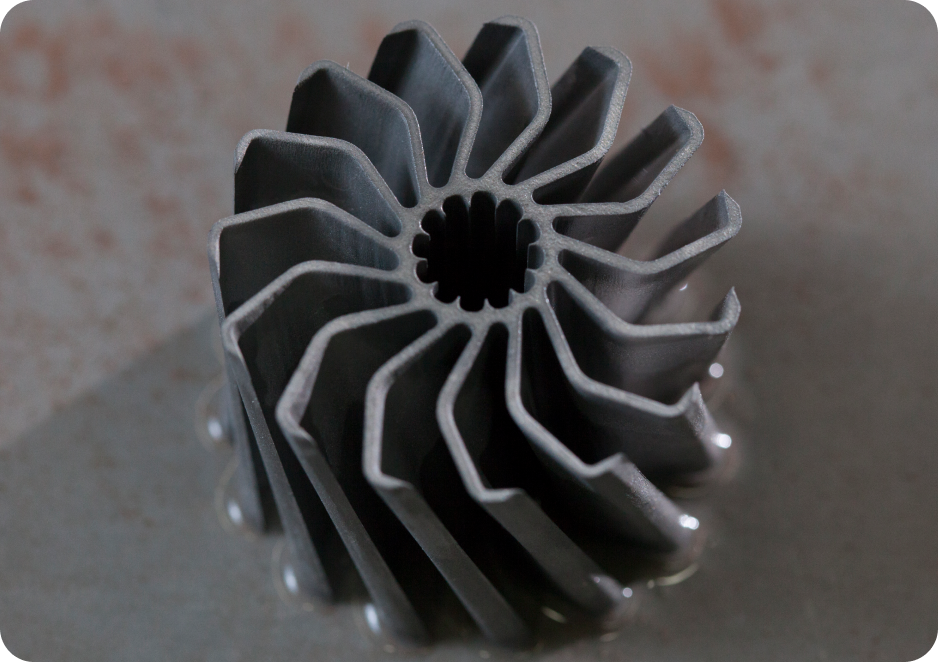

Waterjets act as the optimal complement in a machine shop setting. The ultimate utility solution, a Flow waterjet opens the door to new opportunities with the versatility to perform in ways no other machine tool can – cutting virtually any material, any thickness, in any shape. These attributes make waterjet the ideal solution for producing parts ranging from ultra-thin shims to thick weldments, or even precision die components such as stripper plates.

Waterjets Are Made For Machine Shops

Within the machine shop world, waterjets are often used to streamline operational efficiencies, provide faster rough cutting for thick materials, or produce highly repeatable, tight tolerances up to .001".

The smooth, clean-cut edge, and cold cutting process allows you to reduce secondary processing and allows cutting of hard and soft materials on the same system.

Flow Waterjets Deliver:

Tight tolerances • Enclosed solutions • 3D capabilities • Flexibility to cut a wide variety of materials • High performance from prototyping to production

Waterjets + Machine Shops

Pair your waterjet with ultrahigh-pressure for maximum productivity.

Prototype New Materials

Cut Virtually Any Shape

2D or 3D Cutting

Popular Waterjets for Machine Shops

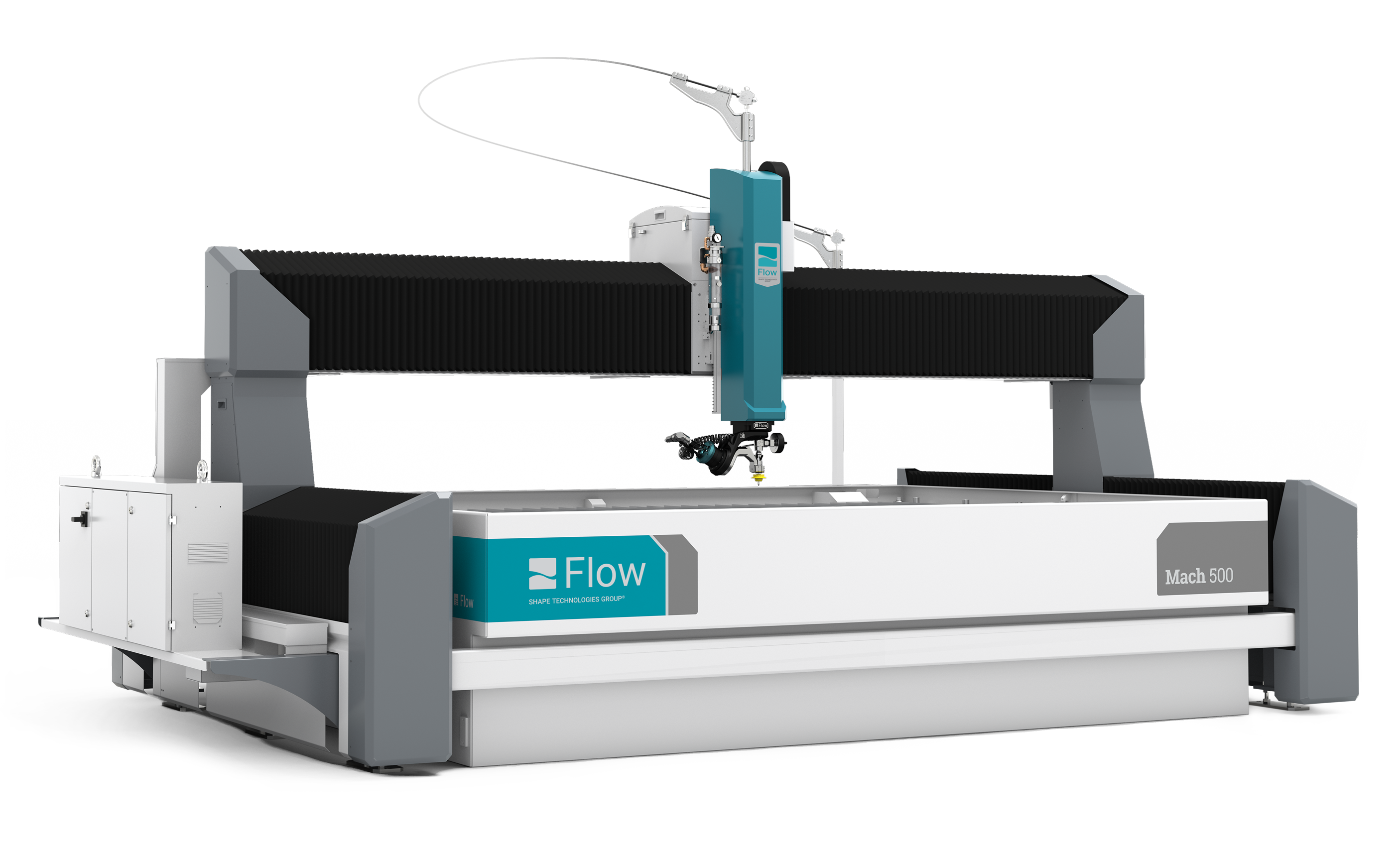

Mach 500

The Mach 500 is the workhorse of waterjet and comes with the widest configurability and options. Select from every Flow waterjet pump or cutting head option to gear your waterjet up for your specific machine shop needs.

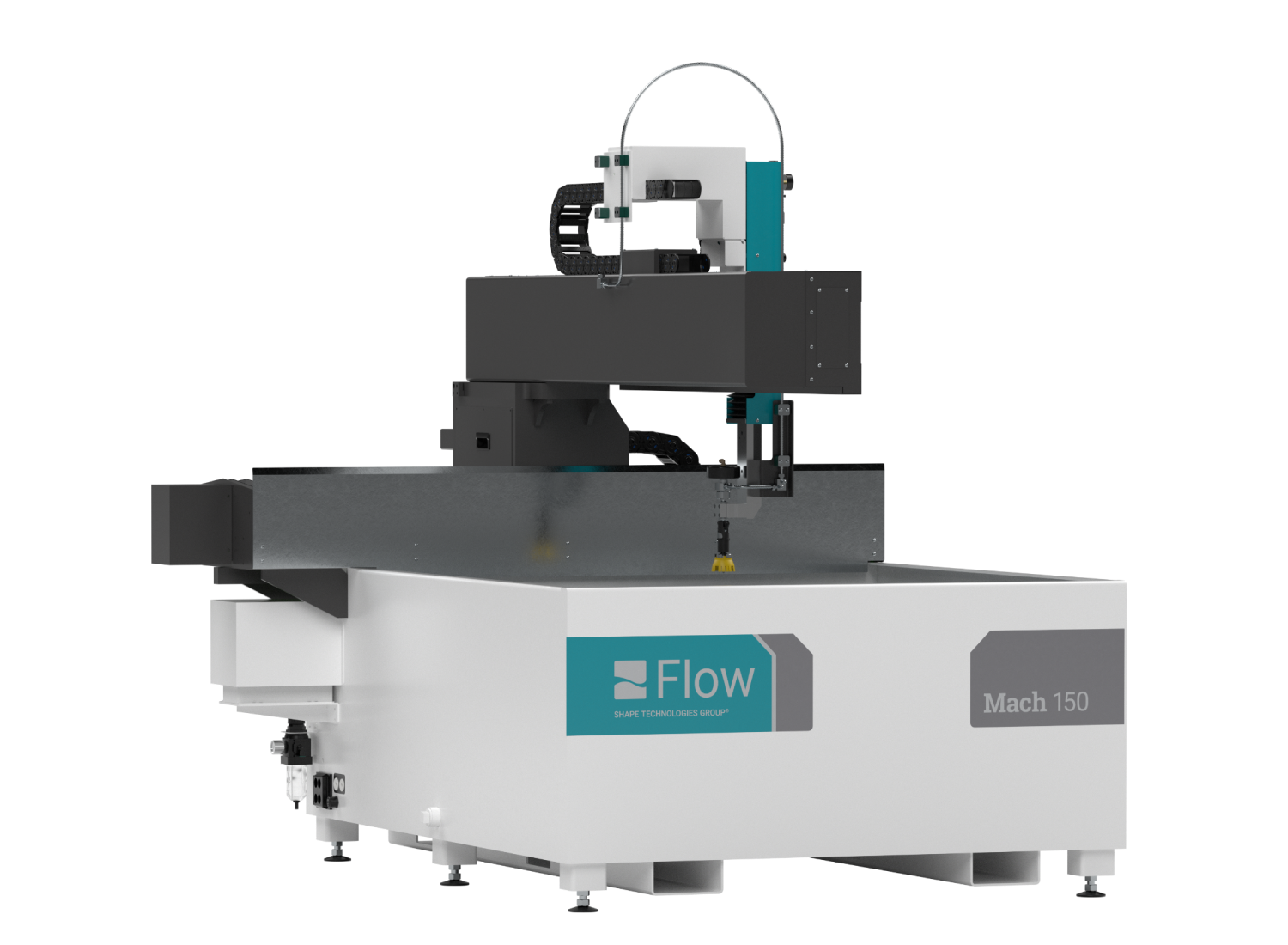

Mach 150

The Mach 150 is a value-focused solution, offering the fundamental versatility of waterjet cutting with no frills. Engineered with the same components as Flow's premium cutting solutions, the Mach 150 features robust cutting capabilities and a programmable Z-axis for added flexibility.