.jpeg)

Tradeshows

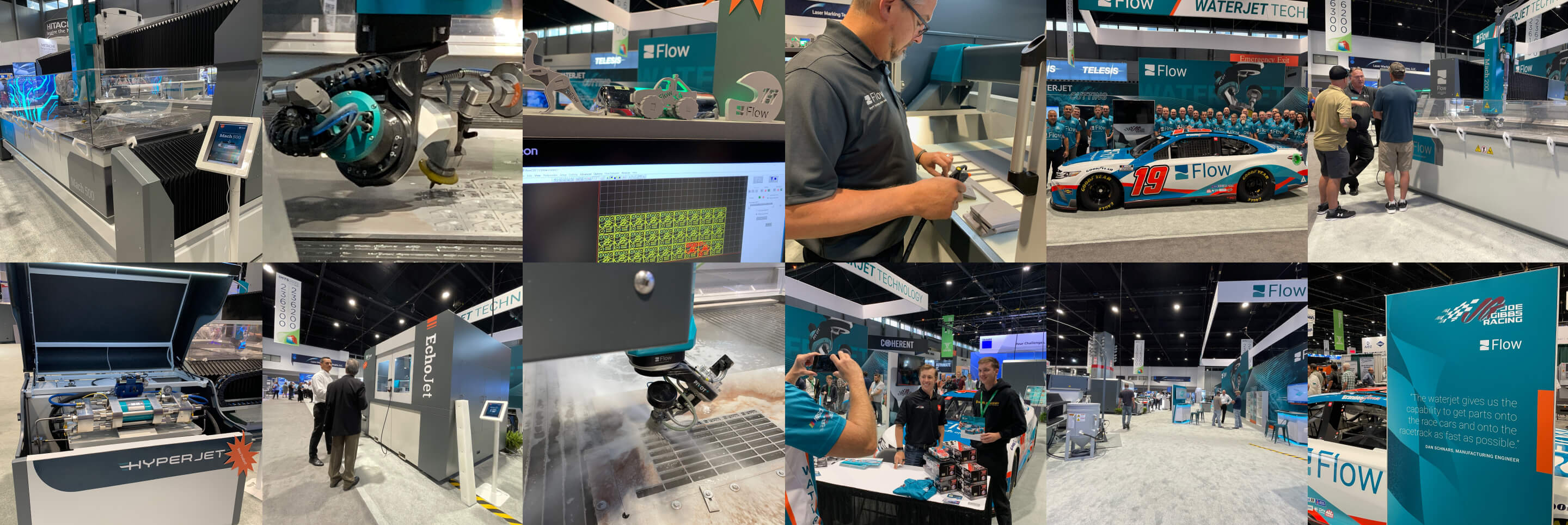

Come see Flow in action

Experience Flow waterjet technology in person. Application engineers will be on hand to answer questions and demonstrate how Flow’s waterjet technology provides fast, accurate cutting across all of our solutions.

United States & Canada Tradeshow Schedule

Canadian Manufacturing Technology Show (CMTS)

September 29, 2025 - October 02, 2025

Toronto, ON

EMEA Tradeshow Schedule

Siane Toulouse

October 14, 2025 - October 16, 2025

Toulouse, FR

Tech Industry

November 27, 2025 - November 29, 2025

Riga, LV

LATAM Tradeshow Schedule

APAC Tradeshow Schedule

MTA

July 02, 2025 - July 05, 2025

Hồ Chí Minh, Việt Nam

Mechatronics Technology Japan (MECT)

October 22, 2025 - October 25, 2025

Nagoya, JP

Manufacturing Indonesia

December 03, 2025 - December 06, 2025

Jakarta, ID