Standard Waterjet

Easily Cut Virtually Any Material

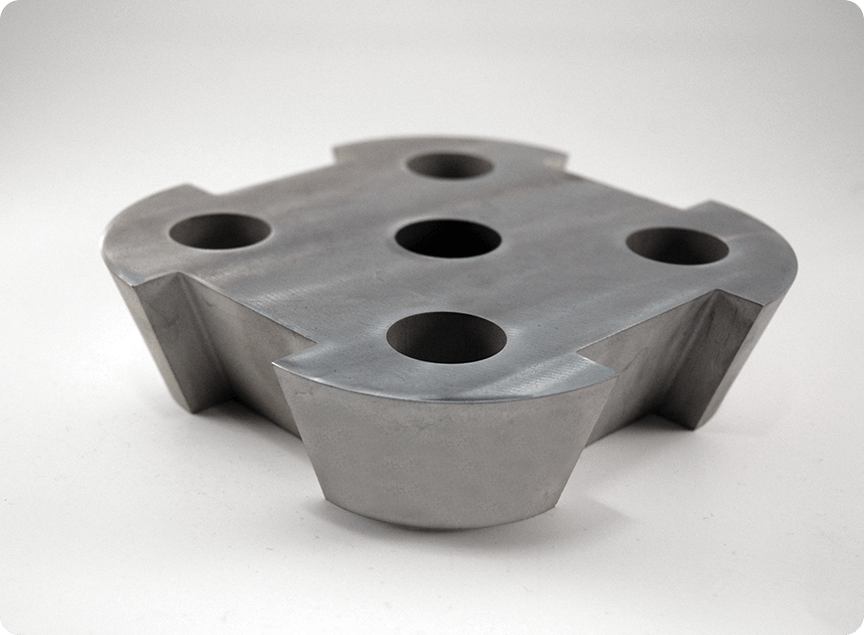

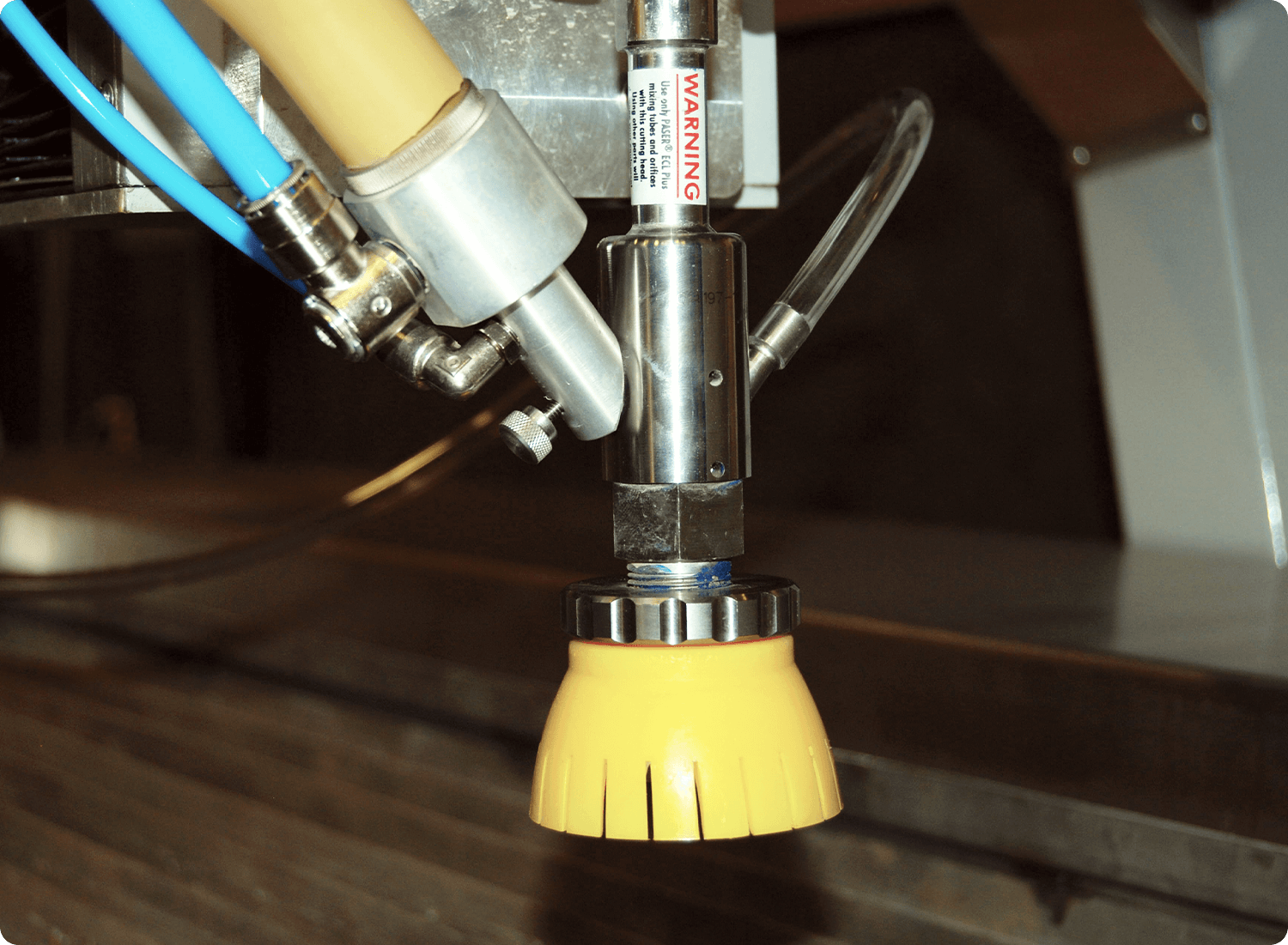

In standard waterjet cutting, the stream remains perpendicular to the material being cut at all times. The supersonic stream accelerates abrasive particles and erodes the material. It is capable of cutting hard materials such as metals, glass, stone, and composites. Using standard parameters, this cutting head can cut materials with hardness up to and slightly beyond aluminum oxide ceramic (often called alumina, AD 99.9) and over 10 inches thick.

.png)

Key Features

Part Quality

No heat affected zones, no mechanical stresses, and extremely detailed part geometry.

Easy Setup

One jet setup for nearly all abrasive jet jobs.

Stacking

Increase productivity by stacking sheet material.

Versatility

Quickly switch to either abrasive or pure water cutting.

Specifications

FlowMaster Software

Part Thickness

Over 10" Thick

[Over 254 mm Thick]

Core Component Options

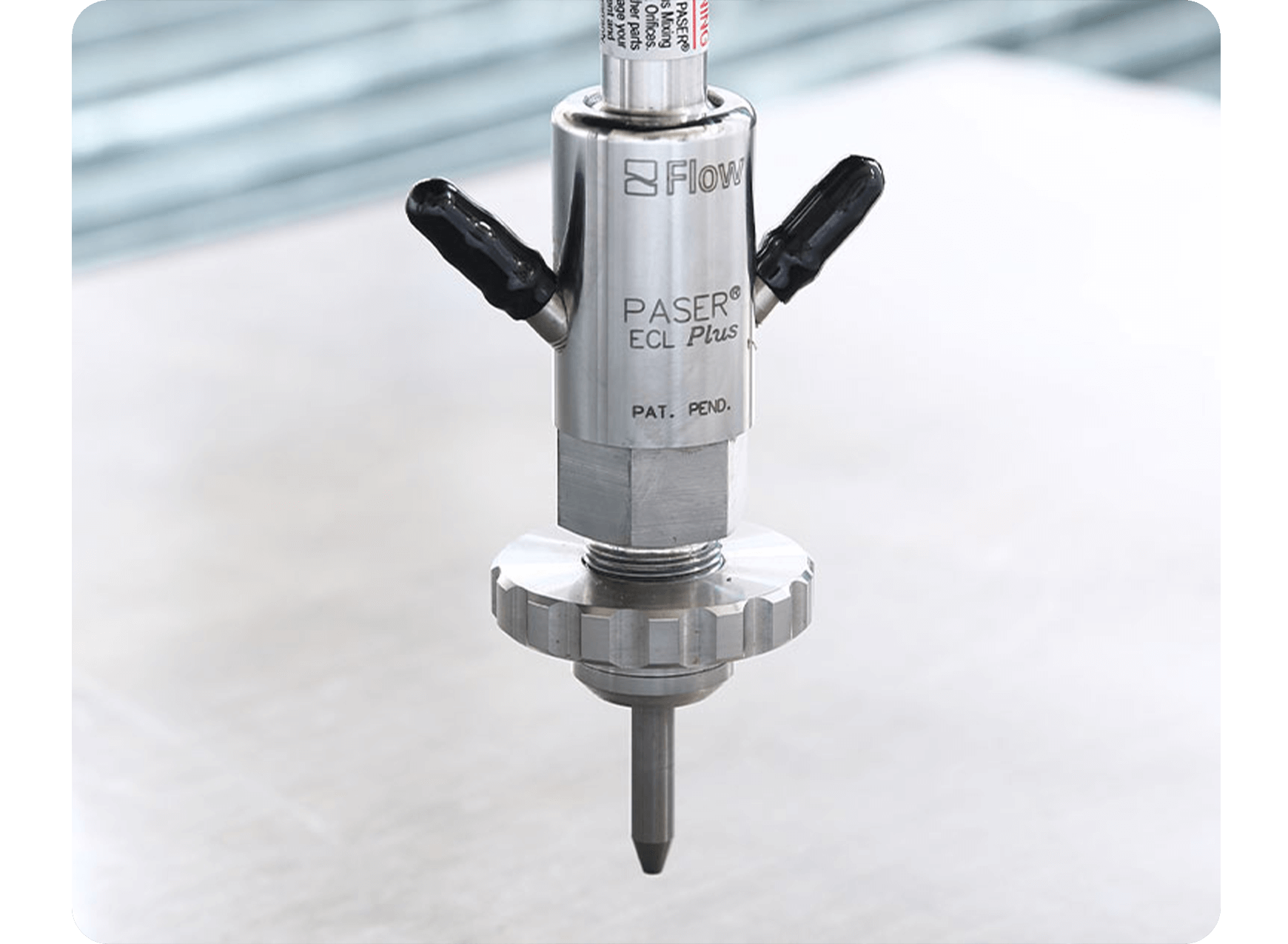

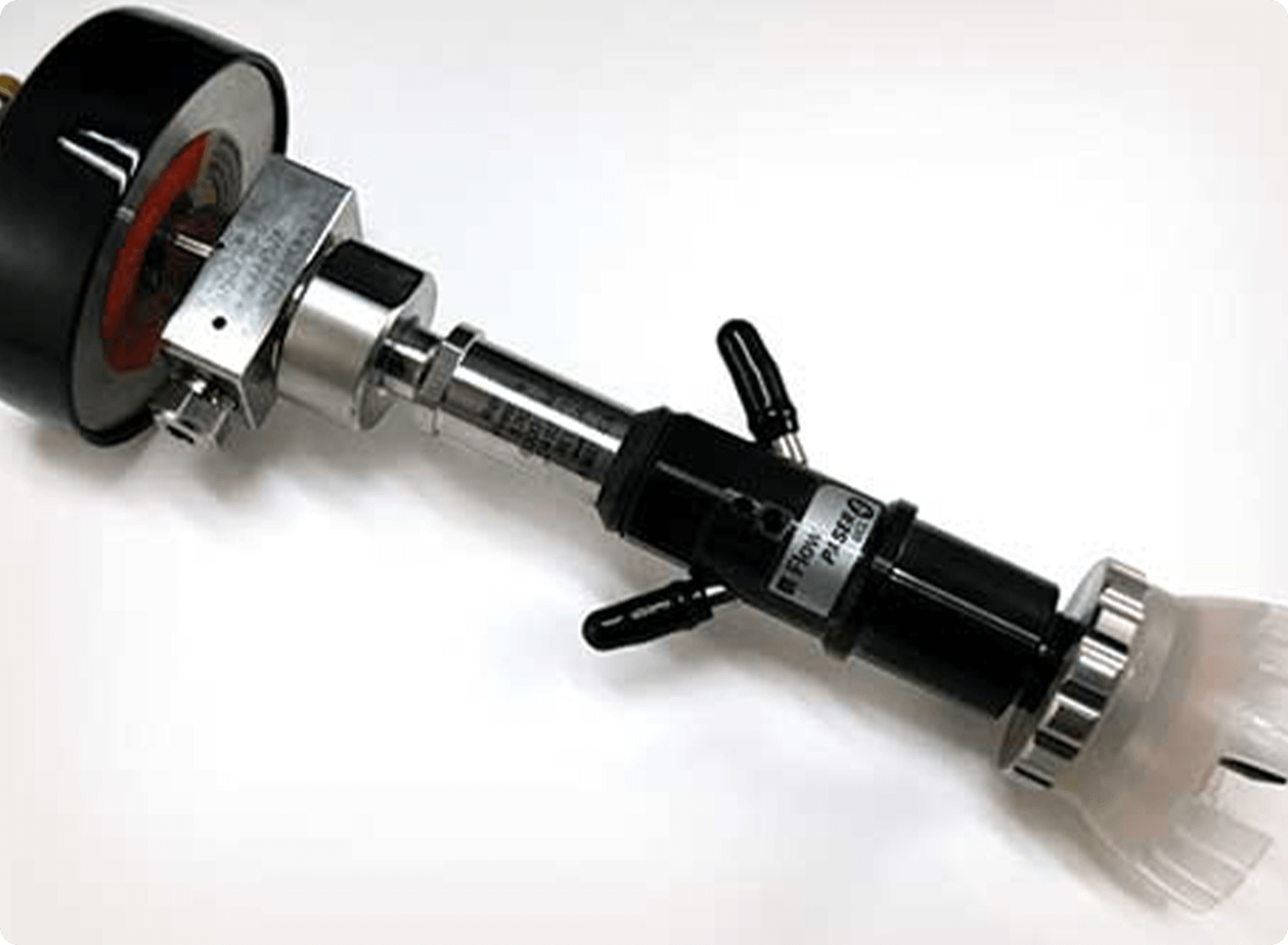

PASER 4 Cutting Head

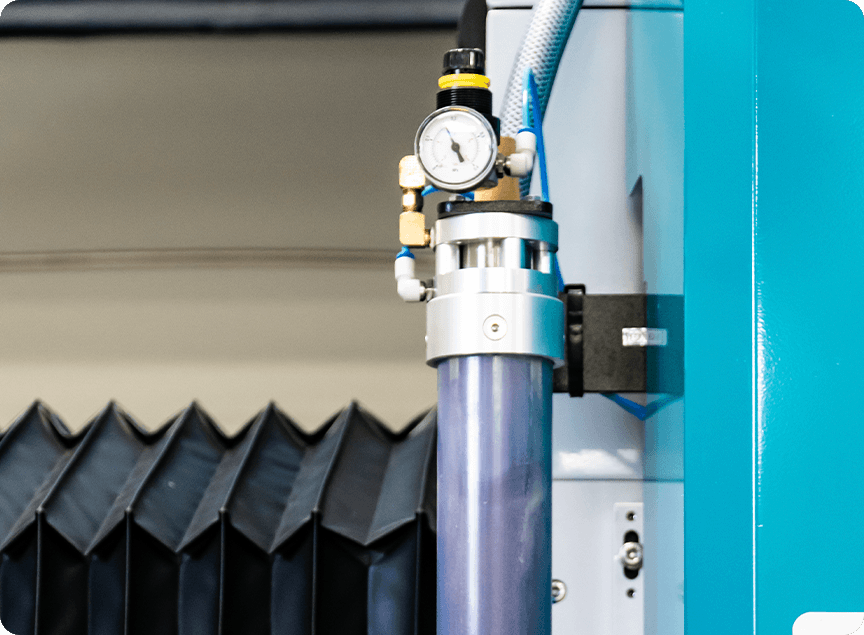

UltraPierce™ Vacuum Assist

Learn More

Dynamic Contour Follower™ and Collision Sensor