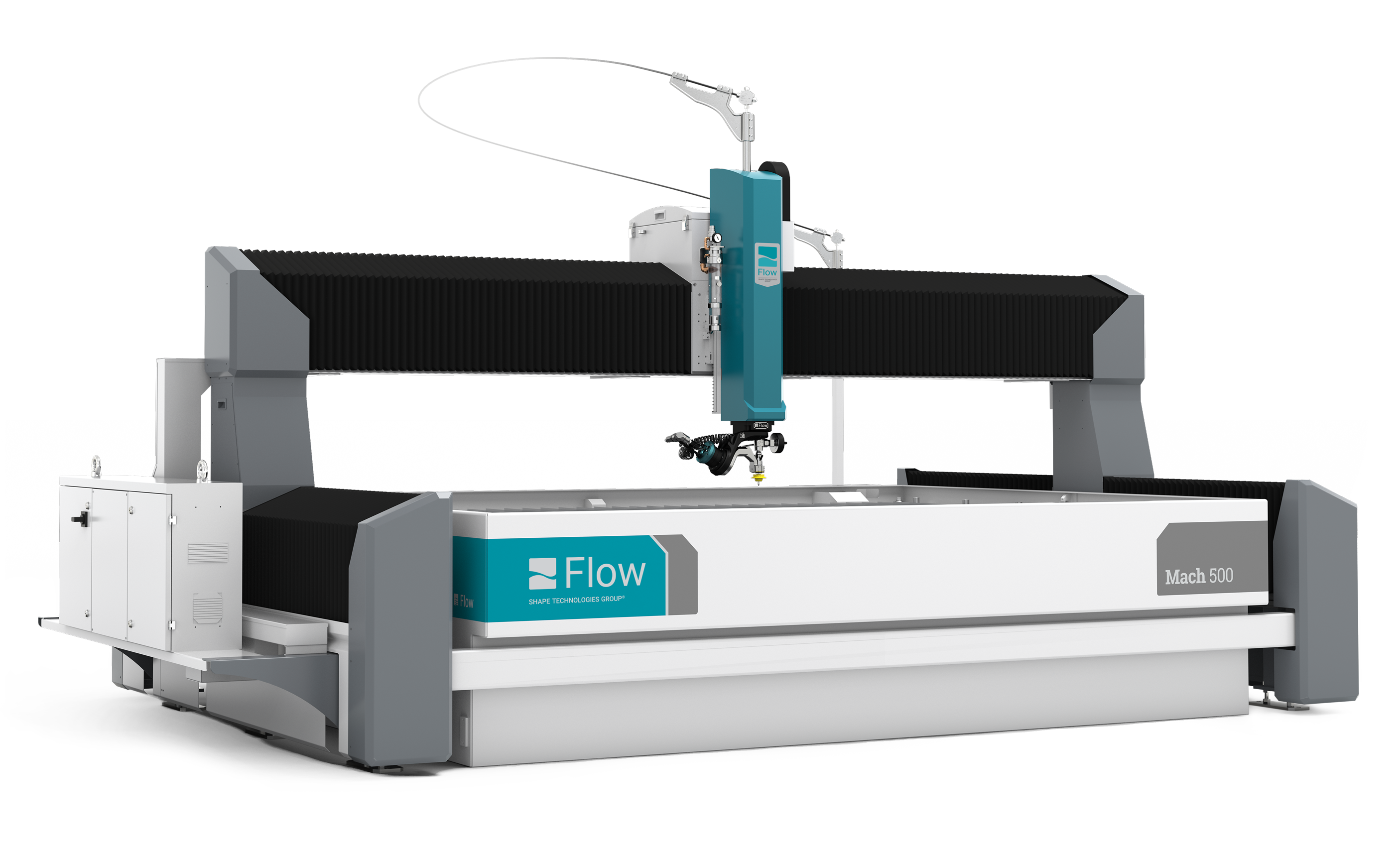

Mach 500

Make More.

The Mach 500 is unmatched in accuracy, quickness and speed, making it your most productive solution. The system is revolutionary in terms of reliability and productivity, backed by the only comprehensive service program in waterjet. Uniquely flexible, the Mach 500 can be everything you want, or just what you need.

Key Features

Modern Architecture

Driven by extensive research and customer feedback, the Mach 500 is the fastest, quickest, most accurate waterjet by design. Designed with the operator in mind, the system is built for production. No other waterjet is quite like this.

Unmatched Accuracy

With the modern architecture, precision motion, and Flow's leading ultrahigh-pressure technology at the core, the Mach 500 is unmatched in speed and accuracy. Paired with Dynamic XD and Compass, there is no waterjet that can compare.

Smooth Motion

The Mach 500 is equipped with top-of-the-line components from leading machine tool suppliers for the machine drive, precision motion system, motion control, and solid model software to create a machine that is the quickest, and most accurate on the market.

Solid Foundation

The ultrahigh-pressure pump technology, machine control, cutting heads, industry-leading software, and advanced wrist articulation pioneered by Flow are the foundation of the Mach 500.

See the Mach 500 in Action

Get a glimpse of what makes our flagship waterjet system one of the most advanced waterjets in the industry. We’ll explore table sizes, cutting head options, pumps, accessories, and more.Mach 500 Series Sizes

General Specifications

Mach 500 3020: 3.05 m x 2 m

Mach 500 3060: 3.05 m x 6 m

Mach 500 4020: 4 m x 2 m

Mach 500 4080: 4 m x 8 m

Mach 500 3020: 10’-0” x 6’-6”

Mach 500 3060: 10'-0" x 20'-0"

Mach 500 4020: 13'-1" x 6'-6"

Mach 500 4080: 13'-1" x 26'-0"

Core Component Options

Cutting Head Technology

Pure Waterjet

Hair-thin pure waterjet stream ideal for cutting soft materials.

Standard Waterjet

Uses garnet abrasive to cut virtually any hard material. Learn more.

Dynamic Waterjet®

Three times faster and more accurate than Standard Waterjet. Learn more.

Dynamic Waterjet® XD

Accurate 5-axis motion, capable of cutting compound angles with high accuracy. Paired with Compass, Dynamic XD is the fastest, most accurate, cutting head with the greatest amount of flexibility. Learn more.

Pump Technology

HyPlex® Prime

60,000 psi [4,150 bar]

The highest pressure, most advanced direct drive pump available today, with pressures rated at 60,000 psi [4,150 bar]. Learn more.

MotoJet®

60,000 psi [4,150 bar]

With continuous operating pressure at 60,000 psi [4,150 bar], the MotoJet is built for the demands of high-production environments. Learn more.

MotoJet® X

60,000 psi [4,150 bar]

Engineered to maximize uptime, minimize maintenance, and outlast and outperform the rest. It's the longest lasting pump in the industry. Learn more.

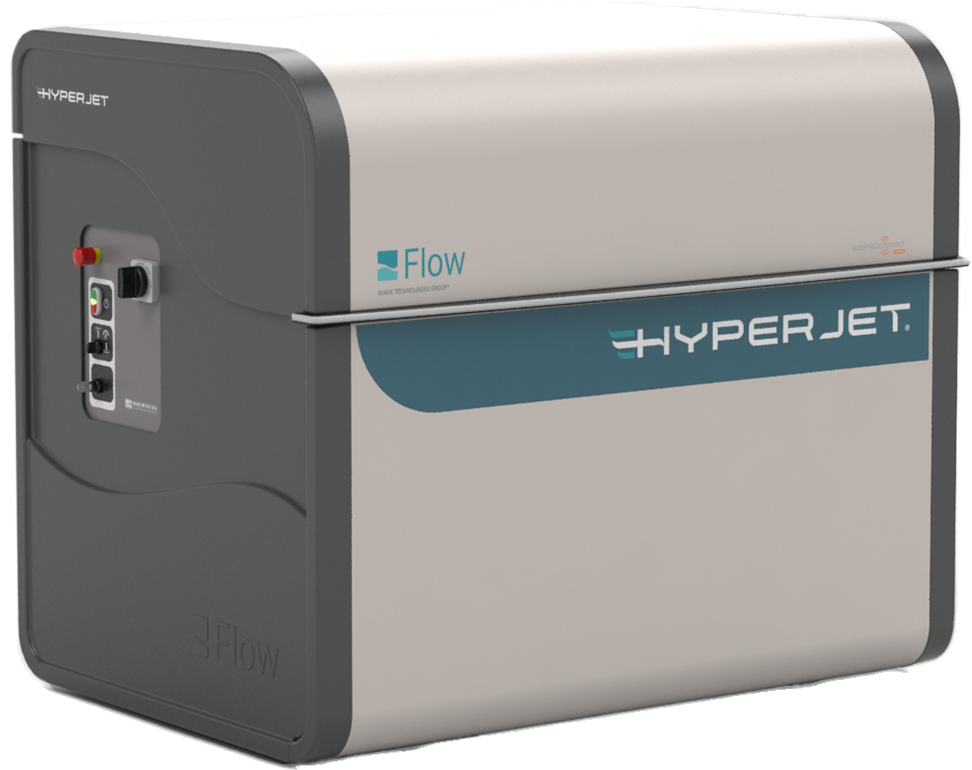

HyperJet®

94,000 psi [6,500 bar]

Provides maximum productivity with continuous operating pressures of 87,000 psi [6,000 bar]. Learn more.

Software Suites

FlowMaster

The FlowMaster software suite, consisting of FlowCut, FlowPath, and FlowNest has everything you need to design and cut 2D waterjet parts. Learn more.

FlowXpert

The FlowXpert software suite, consisting of FlowXpert Infinity, FlowCut, and FlowNest gives you all the tools you need for both 2D and 3D cutting. Learn more.

Service Guarantee

We are committed to providing you with the tools you need to keep your system running at its best. Professional training is available in both classroom settings, as well as on-site.

Best for these Applications

You might also like…

Customer Story

IRC Aluminum & Stainless Steel

To meet the growing needs of the aluminum boat industry, IRC acquired their first Flow waterjet in the mid-1990s. This allowed them to expand into cutting services to complement their distribution. Nearly 30 years since, their company has transformed through that investment.

Read More

Article

Fixture Well & Often

Everyone who cuts parts out of raw stock or a work-piece knows you can’t cut a good part if it isn’t sufficiently held in place. So, what do we have to consider when we’re talking about waterjet cutting?

Read More