From Field Services to Manufacturing Through Waterjets

Miller Industrial Manufacturing, formerly Miller Mechanical Services, began as a field services group for the pulp and paper industry. Over the past 30 years, they’ve diversified to provide engineering solutions, metal fabrication and machining, and pulp and paper installations, as well as provide solutions to other industries. In 2011, they purchased their first Flow waterjet for their newly opened machine shop. Since then, they’ve added two more Flow waterjets to their shop and expanded their service offerings.

Miller Industrial Manufacturing

Miller Mechanical, founded by Myles Miller in 1988, began as a field services group for the pulp and paper industry. Determined to provide their customers with the highest quality possible, they’ve become recognized as the leader in the business. Over the past 30 years, they’ve diversified to provide engineering solutions, metal fabrication and machining, and pulp and paper installations, as well as provide solutions to chemical, pharmaceutical, construction, and power generation industries.

Pictured: Left: Glens Falls Coal Company originally operated out of the building. Right: Miller Mechanical opens.

Miller Mechanical’s machine shop opened in 2011, when their first Flow waterjet was purchased, to manufacture parts and to cut other required materials for their pulp and paper installations. Within just a couple of years, they opened their services to outside clientele, essentially creating a side business around their waterjet. In 2023, with three Flow waterjets* in operation, they rebranded their waterjet business as Miller Industrial Manufacturing. They cut thousands of tons of material per year, consisting mostly of stainless steel and carbon, though they also cut acrylic, granite, and other materials. Most of their projects are cut with their waterjet, but they also operate a plasma table, CNC mill, and other various fabrication equipment.

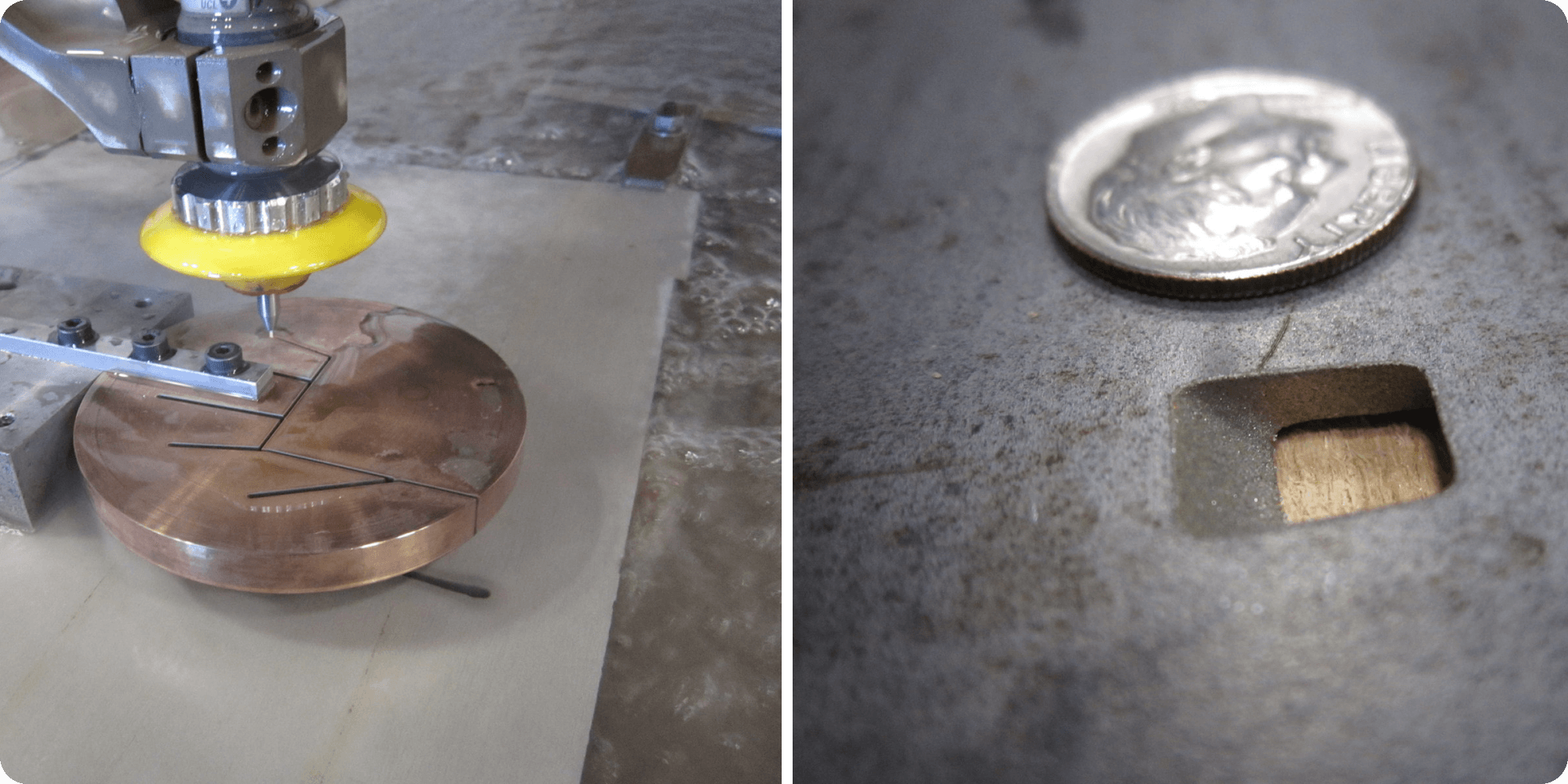

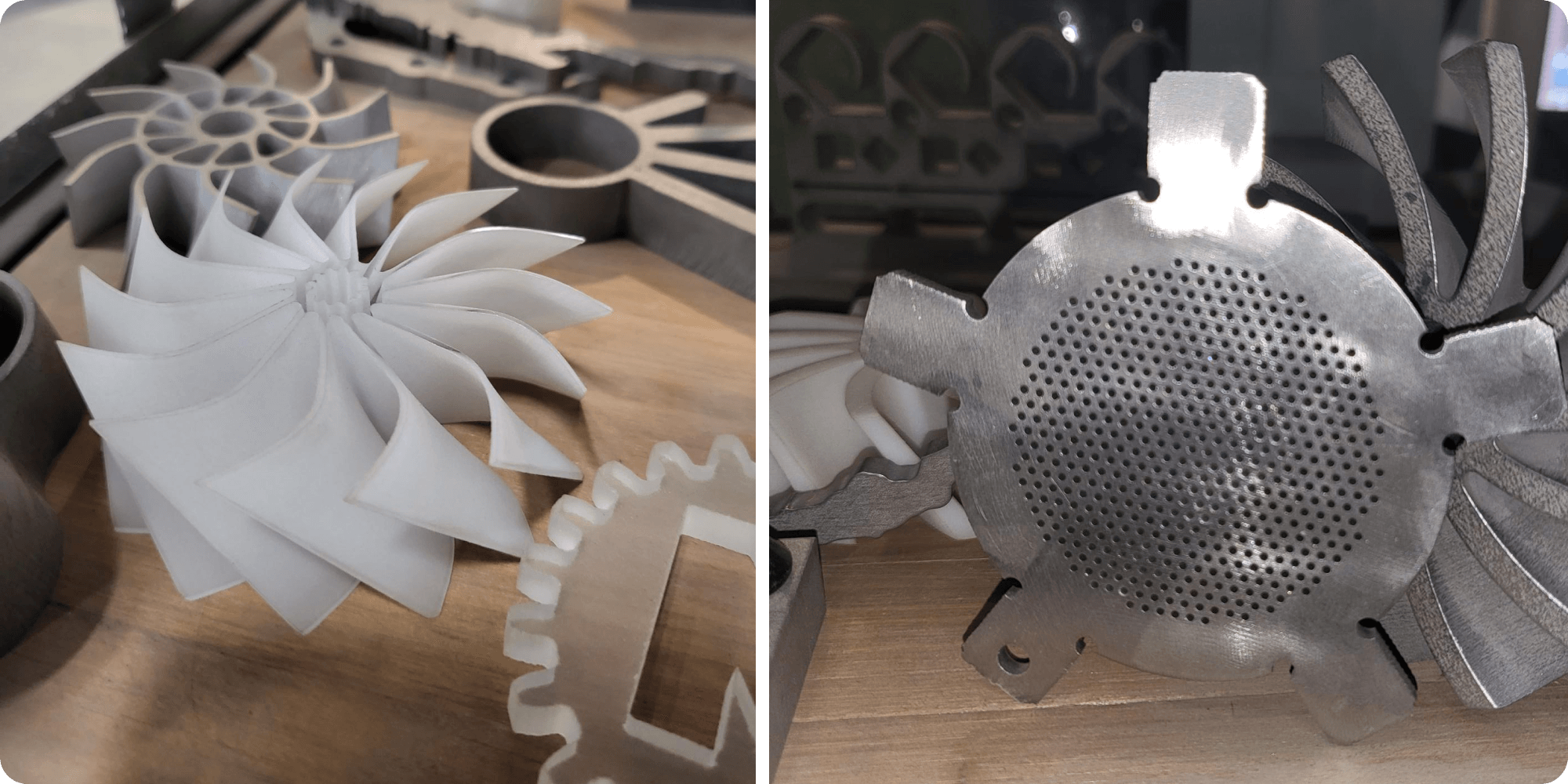

Pictured: Intricate cuts done by the Flow waterjets at Miller Industrial Manufacturing.

Peter Lockart, Miller’s Waterjet Department Manager, joined the company in 2021. With experience cutting on competitor’s waterjets since 2005, he was apprehensive about the Flow systems and almost pushed to convert the two they’d had at the time to a competitor’s system. “I realized after using the machines for a week, two weeks, they were considerably better. In just the way they operate, the way they cut. It was just night and day. Flow won me over."

"This part [servo mount blank below] would have been impossible without the Mach 500. The steep angled square sides cut perfectly with the Mach 500, then we machine the rest to print."

Pictured: Cut 3D blank for a finished servo mount.

Challenges he’d experienced with his previous company’s system included part accuracy, edge quality, taper issues, and limited pressure options. “We could never get it [cut parts] right,” Peter mentioned. “It caused a lot more work.” What features won Peter over? The taper compensation and the pressure are his favorites. “Flow systems are more powerful and more accurate. Cutting nice parts, the first time, is what did it for me."

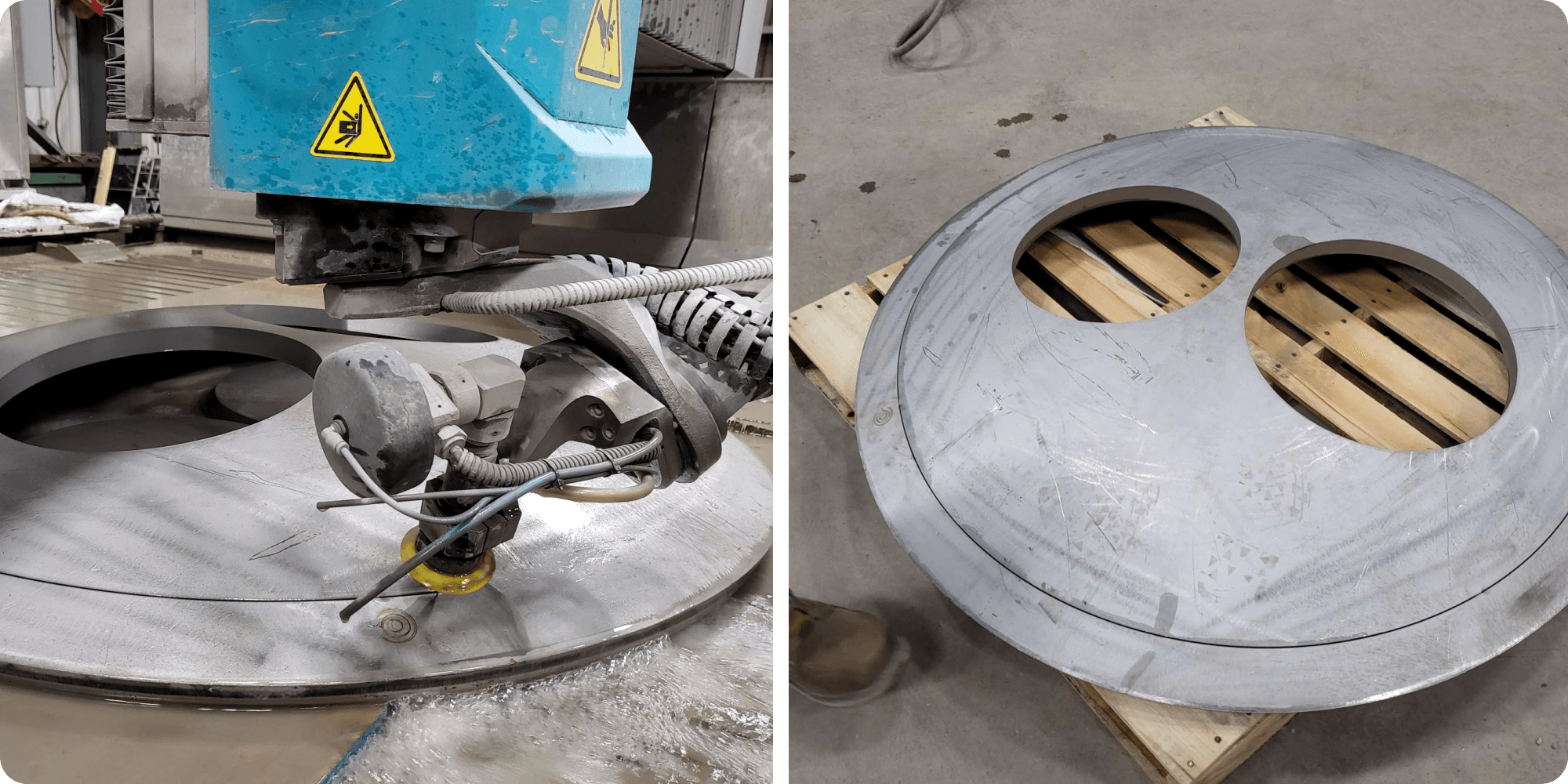

Pictured: A reinforcement dome for a pulp digester. All features were angled cuts on top of the fact the dome itself was 3D. Each feature had a specific angle to be cut at.

Advice he has for someone shopping for a waterjet: “Get a Flow. FlowCare makes it easier getting started. Machines are easier to service. Customer Service is fantastic; I’m always able to get my questions answered quickly. Flow is still innovating and it’s obvious with the three different systems we have.”

Notable projects for Miller Industrial Manufacturing include the sign at Park & Elm in Glens Falls, NY and the granite exterior for a major tech mogul’s building in New York City. The Park & Elm sign was waterjet cut and welded in-shop before being painted offsite. The building’s granite exterior (thousands of tons of it) was all waterjet cut then transported for installation.

Pictured: Completed and installed sign at Park & Elm restaurant in Glens Falls, NY.

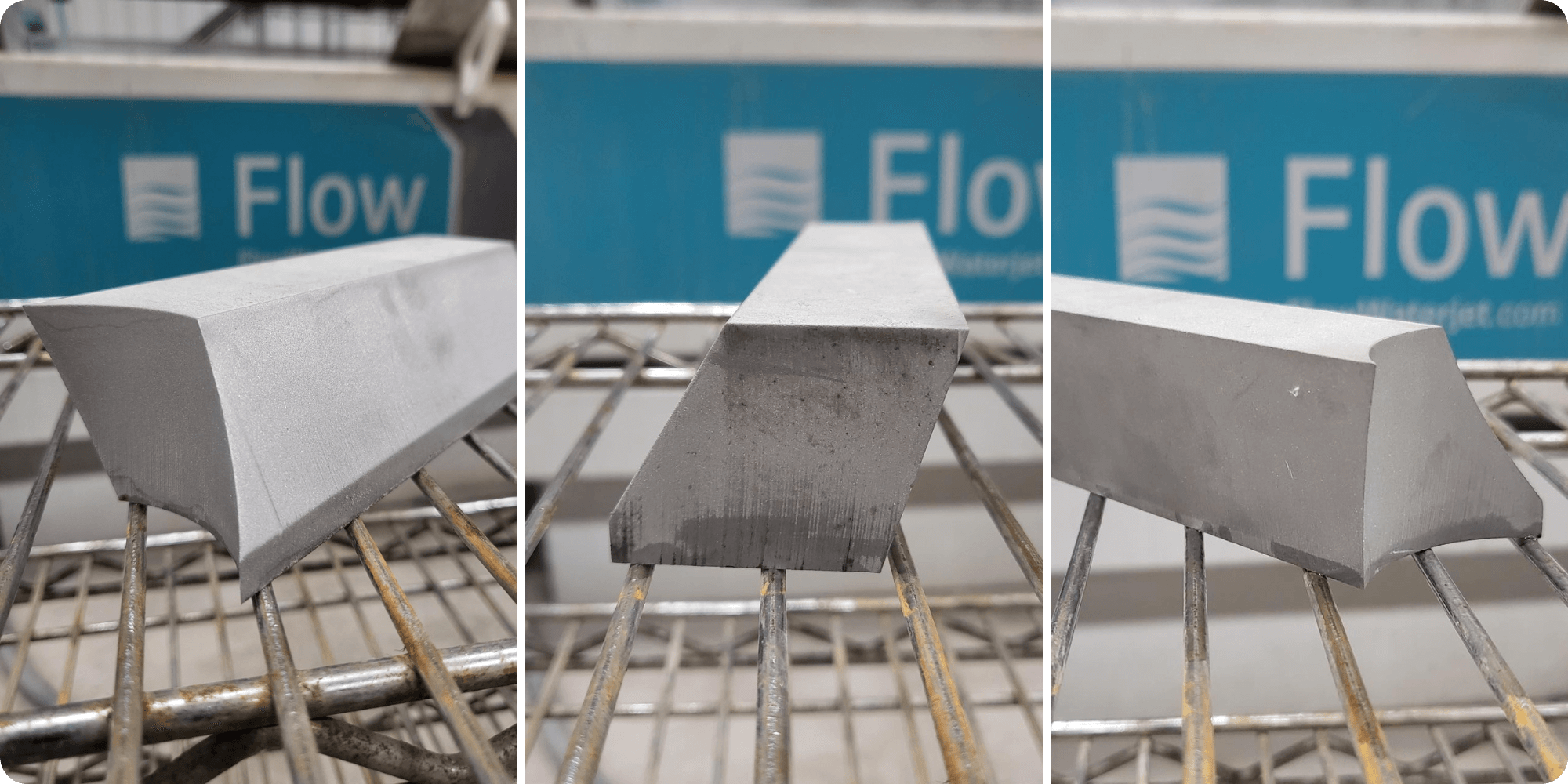

Pictured: Rough cut waterjet parts with approximately .010" left on edges to machine to finish size.

Pictured: Multi-feature bevel for Pulp Digesters.

Pictured: Left: Acrylic water pump impeller in case of sample parts. Right: Filter screen with .040" holes for paper assembly.

*In 2014, they purchased a Mach 3b 4020 with Dynamic Waterjet™ XD and HyperJet pump. In 2020, they added a Mach 500 3020 with Dynamic Waterjet™ XD and HyperJet pump, and in 2022, they added their third machine: a Mach 500 3020 with Dynamic Waterjet™ XD and HyperJet pump. In 2023, Miller Mechanical Services is now Miller Industrial Manufacturing.