FlowMaster®

Software Suite

The FlowMaster, Simple Yet Powerful, software suite combines everything you need to design and cut your 2D waterjet parts.

FlowCut®

FlowCut is the machine tool controller, and it is smarter and easier-to-use than any other machine control software. FlowCut knows Waterjet: No knowledge of CNC or waterjet cutting required.

- Open your ORD file

- Select material type and thickness from a huge list

- Run the machine to cut your part

Effortless Importing

Waterjet Expertise

Fully Integrated

Software Features & Requirements

- User-friendly, icon-based menu structure

- Supported Languages: English, Chinese, French, German, Italian, Japanese, Korean

- Operating Systems: Microsoft® Windows 7 and newer

- CPU: Pentium 4 2.0 GHZ or Athlon 2000+ or faster; 32-bit (x86) or 64-bit (x64) processor; RAM: Minimum: 512MB RAM (32-bit); 1Gb RAM (64-bit)

FlowPath®

FlowPath takes the guesswork out of making high quality parts regardless of operator skill level; No G-code required.

- Import your 2D file or create your own design

- Examine the drawing to detect any geometry errors

- Select the geometry and autopath, the system automatically creates lead in, lead outs, and traverse lines

- Many other waterjet specific features available at the touch of an icon

- Save the ORD and send the file to the machine, FlowCut does the rest

Intuitive Interface

Waterjet Knowledge Built In

Optimize Your Process

Software Features & Requirements

- Windows based

- Imports industry standard DXF, DWG, IGS, CADKEY, CDL, and HPL files

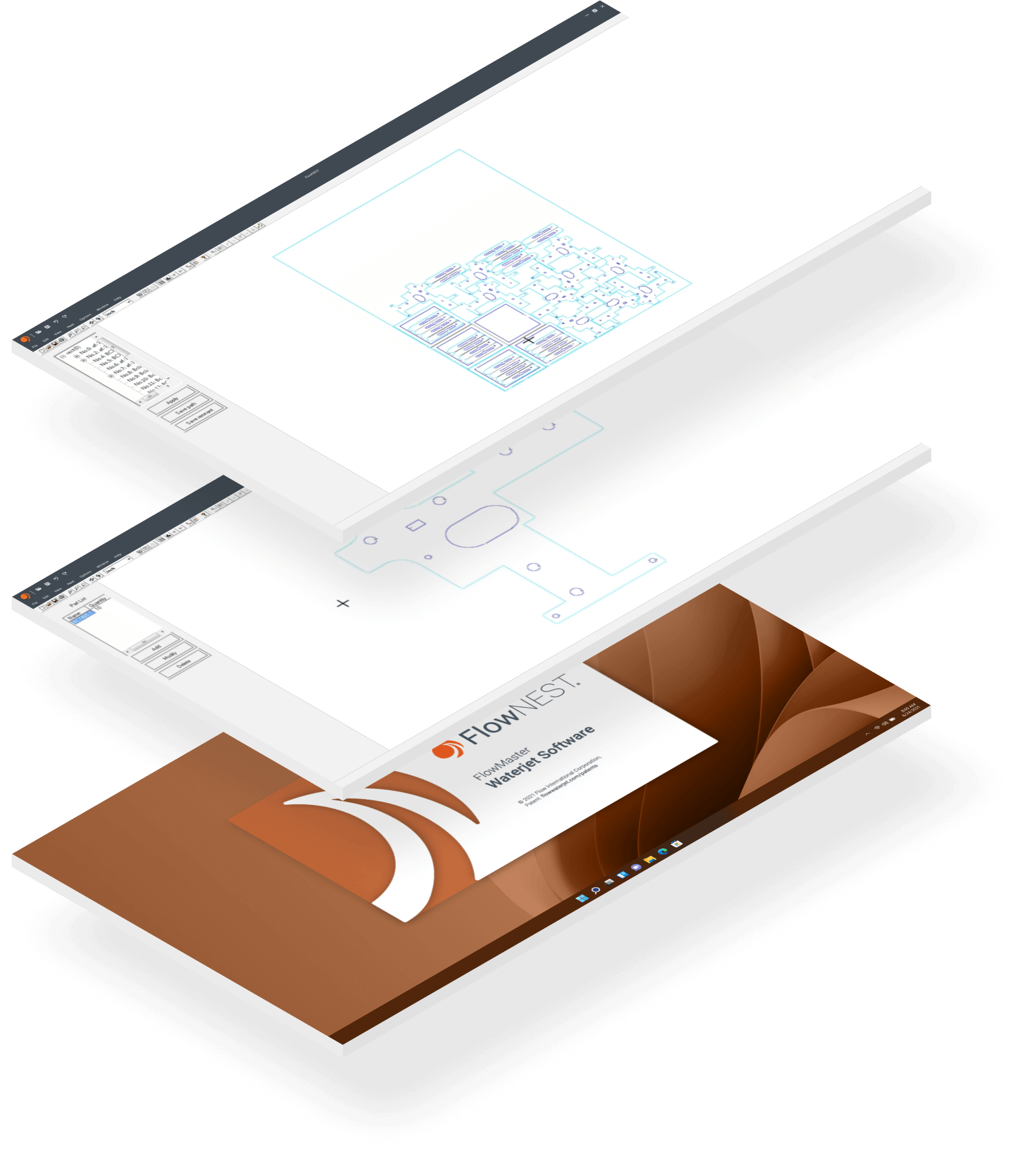

FlowNest®

FlowNest is a simple, 2D geometric nesting module that allows parts to fit inside scrap areas of other parts – allowing the most efficient use of material. Maximize your material with FlowNest.

- Import your standard DXF or Flow specific ORD part files

- Select part quantity, degree of rotation angle, and priority

- Choose sheet size, which can be a standard sheet size or a remnant

- The system will automatically nest your parts

- Save the nested file as an ORD and send to the machine, FlowCut does the rest

Efficiency Gains

Optimize Your Process

Software Features & Requirements

- User-friendly, icon-based menu structure

- Supported Languages: English, Chinese, French, German, Italian, Japanese, Korean

- Operating Systems: Microsoft® Windows 7 and newer

- CPU: Pentium 4 2.0 GHZ or Athlon 2000+ or faster; 32-bit (x86) or 64-bit (x64) processor; RAM: Minimum: 512MB RAM (32-bit); 1Gb RAM (64-bit)