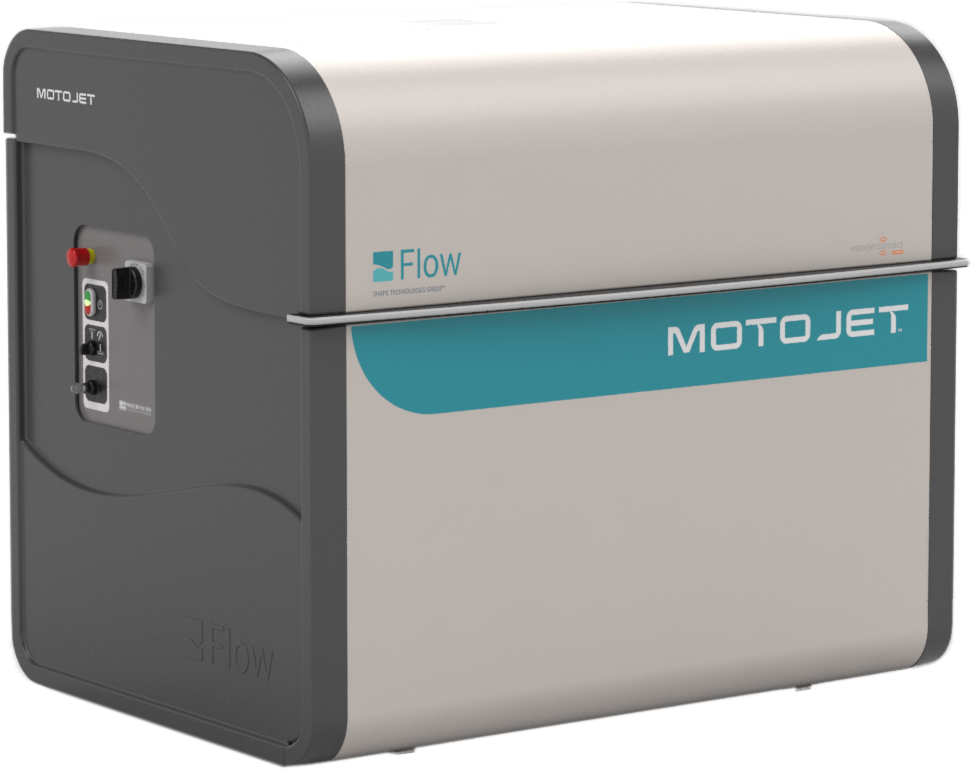

MotoJet®

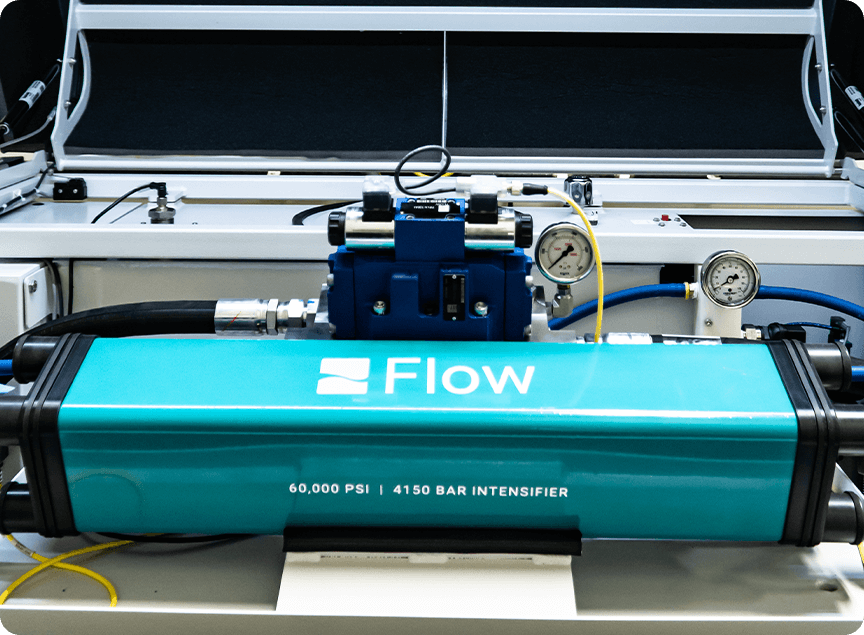

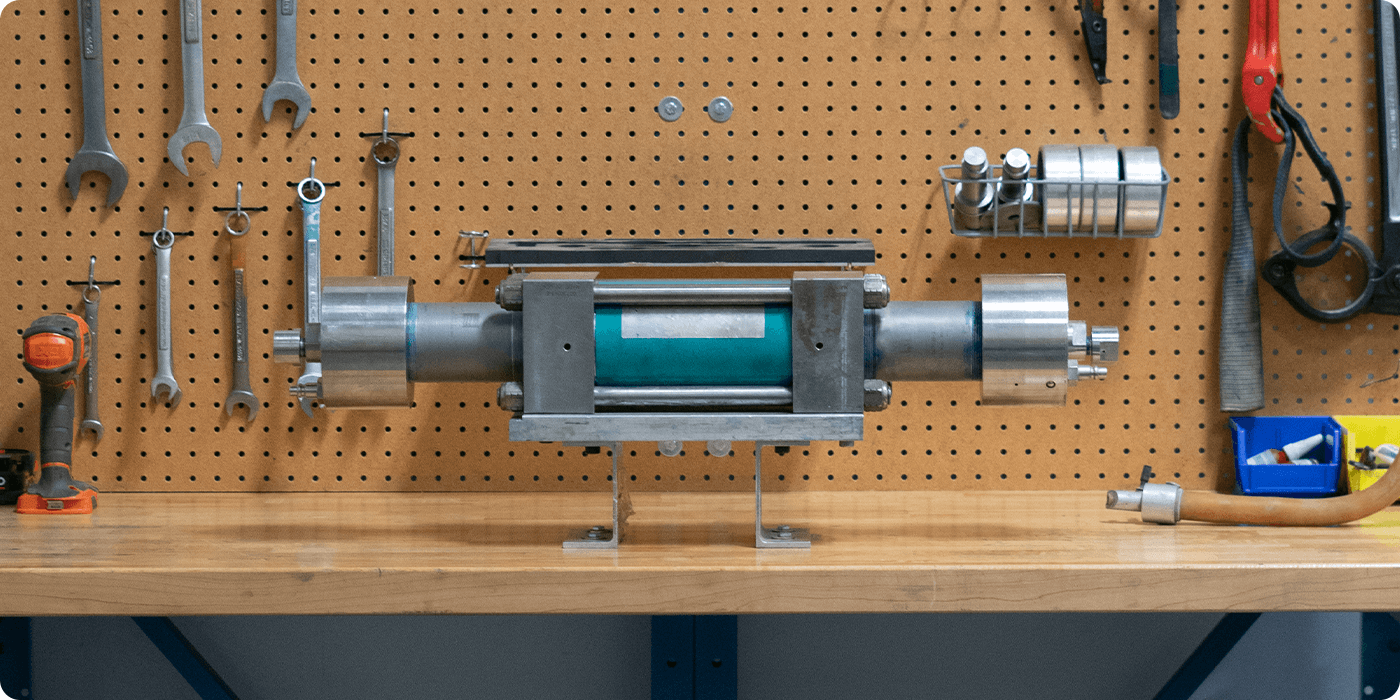

60,000 psi [4,150 bar] Intensifier Pump

The MotoJet intensifier pump sets the industry standard for waterjet and abrasive waterjet cutting applications. Manufactured for the demands of high-production environments, the MotoJet is built for dependability.

Key Features

Fully Electronic Dual Pressure Control

Pressure setting and control is integrated into the machine operator station, greatly enhancing operator convenience. Designed for applications where a low-pressure pierce may be necessary before a higher pressure cutting operation, the dual pressure control provides a simple way to switch between two output pressures.

Maintenance-Free Attenuator

With the largest pressure-shock attenuator available (124 cubic inch or 2.02 liter), Flow pumps deliver consistent water pressure every day. No maintenance is required.

User-Friendly Pump Enclosure

The pump enclosure is visually and functionally integrated into the machine tool system and features convenient, user-friendly designs: air assisted lifting top, removable side panels for full maintenance accessibility, handle-integrated status light, interior work light, and sound deadening materials.

Cooling Water Flow

Thermostatically controlled valve regulates cooling water flow while minimizing water usage. This enhances pump performance and optimizes inlet water usage.

General Specifications

Service & Support

The MotoJet is backed by Flow's global service network. Technical documentation, phone support, and on-site maintenance plans are a few of the ways we offer support to our customers. Click here to learn more about our service plans.

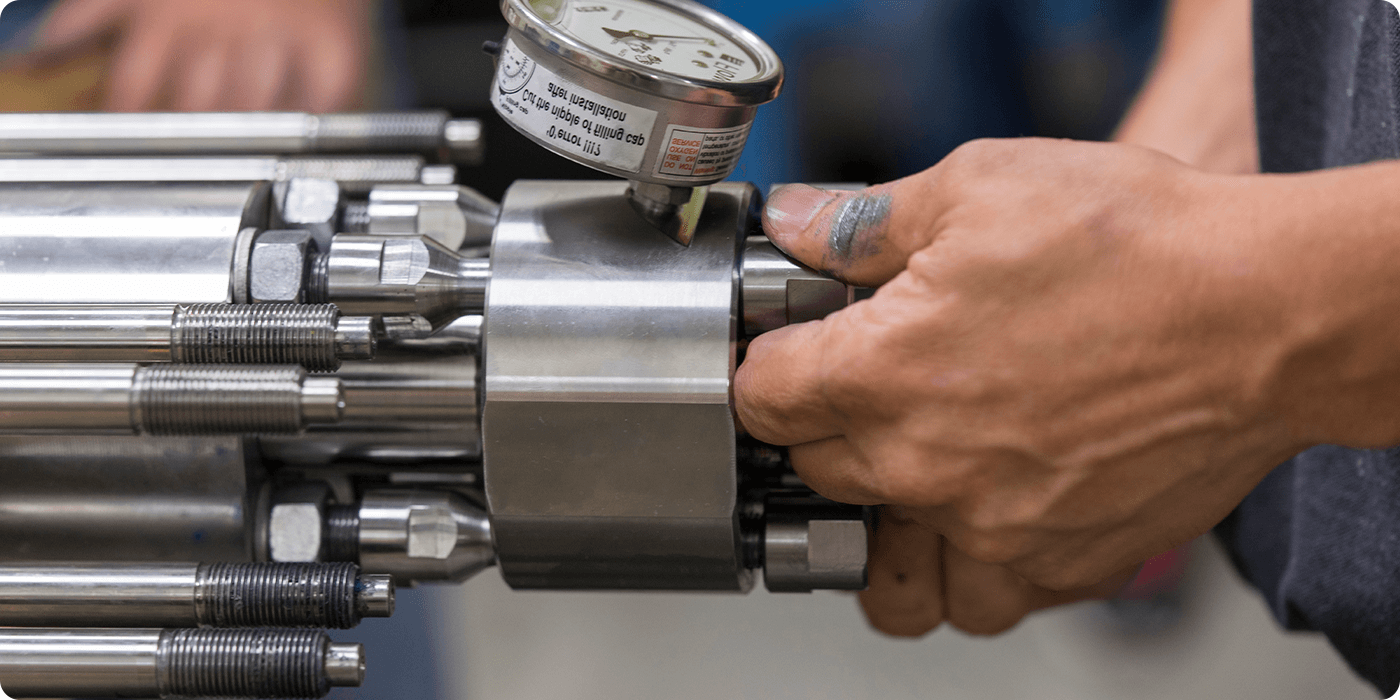

Maintenance

The MotoJet intensifier was designed for easy operation and reliable performance. It delivers the most reliable ultrahigh-pressure at full pressure for basic or 24/7 operation. Constantly monitored by advanced diagnostics, it provides a constant stream of performance information designed to maximize your uptime. As the most popular pump in the world, you can perform maintenance quickly, or leave the maintenance to Flow with a dedicated service plan.

Safety by Design

This pump is designed for safe, reliable, continuous operation at 60,000 psi [4150 bar] in tough industrial cutting applications. An automatic high-pressure bleed-down valve relieves system water pressure to 0 psi [0 bar] within one second of shutting down the pump.Flow's pumps are manufactured in a facility that follows the strictest rules of manufacture and safety, including extensive metallurgical testing and full source tracing of the highest-performing metal alloys available.

Equipped with Waterjet Connect™

Every MotoJet pump comes equipped with Waterjet Connect — your unique, one-stop-shop for accessing all things related to your waterjet system. Order parts, schedule service, view your order history, and more through your Waterjet Connect account.