Comparative Cutting

Waterjets can cut any solid material including stone, tile, glass, metal, foam, rubber, plastic, and food.

When compared with plasma, laser, and EDM - waterjet cutting has distinct advantages. In addition to no heat-affected zone, the benefits and applications for waterjet technology are limitless and ever-expanding.

Process

| Waterjet | Erosion: using high-speed liquid sandpaper. | |

| Plasma | Burning/Melting: using a high temperature ionized gas arc. | |

| Laser | Melting: using a concentrated laser light beam. | |

| EDM | Erosion: using an electrical discharge. |

Secondary Processing

| Waterjet | Usually none. Waterjet is a cold-cutting process that leaves a satin smooth edge. | |

| Plasma | Typically, yes. Slag grinding for removal of HAZ (heat-affected zone) & flattening to eliminate distortion from heat. Assist gas used impacts depth of HAZ. | |

| Laser | Sometimes yes. Removal of oxidized edge and HAZ. Gases used impact depth of HAZ. | |

| EDM | Usually none. Very shallow HAZ imparted. |

Materials

| Waterjet | Virtually any material. | |

| Plasma | Primarily steel, stainless steel, and aluminum. | |

| Laser | A variety of materials, but primarily steel, stainless steel, and aluminum. | |

| EDM | Conductive materials. |

Thickness

| Waterjet | Up to 24 inches, virtually any material. Z-axis constraint is only limit to thickness. | |

| Plasma | Up to 2–3 inches, depending on the material. | |

| Laser | Generally, 1 inch or less, depending on the material. | |

| EDM | Generally, 12 inches or less. |

Part Accuracy

| Waterjet | Up to .001 inch | |

| Plasma | Up to .010 inch | |

| Laser | Up to .001 inch | |

| EDM | Up to .001 inch |

Capital Investment

| Waterjet | $60k–$300k + | |

| Plasma | $60k–$300k + | |

| Laser | $200k–$1M + | |

| EDM | $100k–$400k + |

Machine Setup

| Waterjet | Same setup for all materials. | |

| Plasma | Different setup for different jobs. | |

| Laser | Different gases and parameters for different jobs. | |

| EDM | Different wire types for different jobs. |

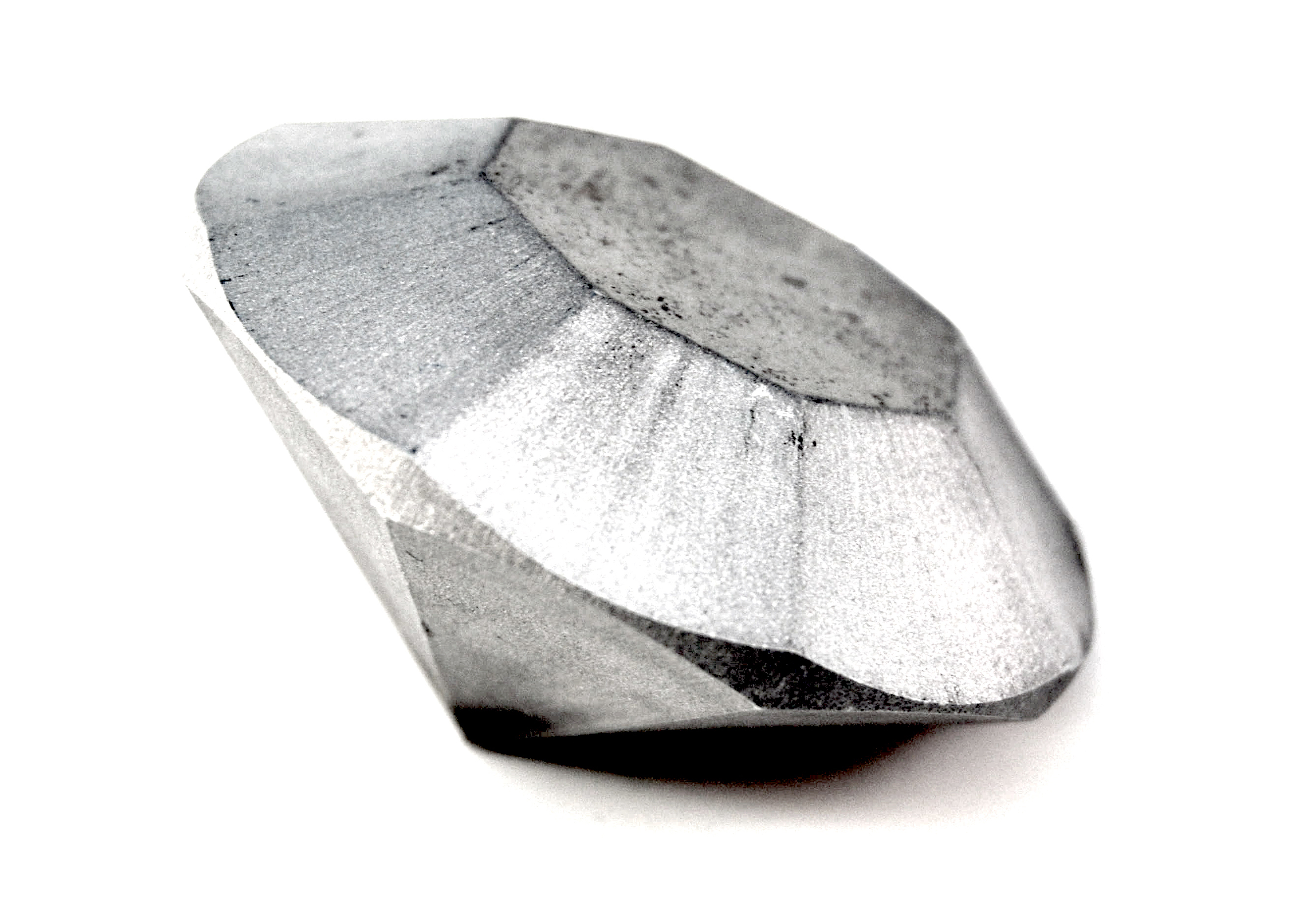

Edge Comparison

Waterjet

Laser

Plasma