How to Make Your Waterjet Work Surface Level

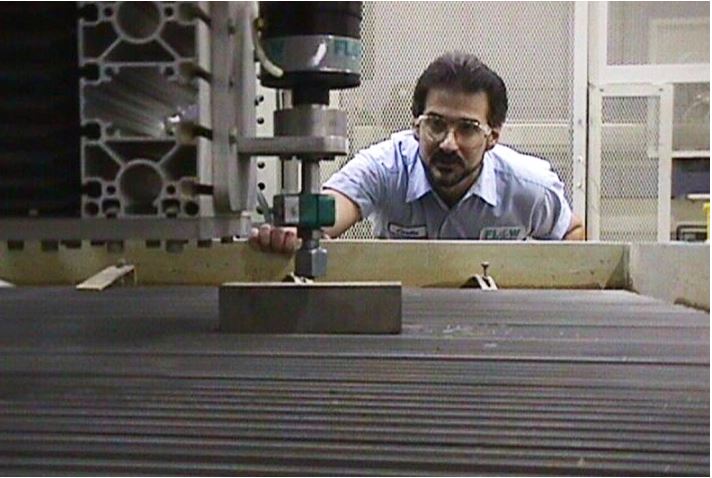

Great machinists know the need for proper fixturing. And they also know the fixturing has to be true to the machine tool motion. Curtis Waffle is a master machinist with well over 35 years at Flow. The large bed of a typical waterjet machine is an XY plane, and that plane must match that of the machine. If the worktable is not flat to the machine motion it creates ongoing headaches and part accuracy and quality issues for the operator.

Flat work surfaces are especially important when cutting with Dynamic Waterjet® or 3D parts. In both cases the head can articulate off of 90 degrees (perpendicular). Unexpected change in the standoff between the nozzle tip and the target material will result in finished part accuracy errors whenever the head is at an angle to the workpiece plane.

Most of today’s waterjets utilize a slat approach. These slats must be manufactured to the same height (4 inches slats are shown). Slats provide a number of advantages. They can be inserted at an arc to improve weight bearing capacity. When bent it is less likely that you run for a long duration of time directly over a slat. Each slat can be flipped or relocated to ensure even wear and long life to all slats.

Slats need to be the same height of the work surface is to be level. If holding tolerance is hard for you or your slat vendor, then ask to get a full set of slats for your table top off of one manufacturing run. That way they can shear them off of the same setup – usually resulting in better uniformity. Frankly, exact slat height is not nearly as important as consistent slat height. Asking for super tight tolerance slats usually increases slat cost.

In addition to the slats being cut to the same height, the frame that holds the slats should be adjustable. For example, on the machines we provide the slats are held by a picture frame that can be adjusted. It can compensate for a slightly uneven floor and tweak the plane as needed. The most common sizes for waterjet machine tools are 3×2 or 4×2 meters in the XY plane, so there is a lot of area to make level.

My favorite way to level the work surface upon installation is to level the slats to the water within the tank, and then do the same with the machine tool. Making everything level to the water is a simple way of aligning the entire system to the planet (old school, but effective).

So, be kind to your operator and QA department. Reduce rework and improve quality with a level material support surface. Hope this was helpful. Please send your thoughts and requests for future posts.

Flat work surfaces are especially important when cutting with Dynamic Waterjet® or 3D parts. In both cases the head can articulate off of 90 degrees (perpendicular). Unexpected change in the standoff between the nozzle tip and the target material will result in finished part accuracy errors whenever the head is at an angle to the workpiece plane.

Most of today’s waterjets utilize a slat approach. These slats must be manufactured to the same height (4 inches slats are shown). Slats provide a number of advantages. They can be inserted at an arc to improve weight bearing capacity. When bent it is less likely that you run for a long duration of time directly over a slat. Each slat can be flipped or relocated to ensure even wear and long life to all slats.

Slats need to be the same height of the work surface is to be level. If holding tolerance is hard for you or your slat vendor, then ask to get a full set of slats for your table top off of one manufacturing run. That way they can shear them off of the same setup – usually resulting in better uniformity. Frankly, exact slat height is not nearly as important as consistent slat height. Asking for super tight tolerance slats usually increases slat cost.

In addition to the slats being cut to the same height, the frame that holds the slats should be adjustable. For example, on the machines we provide the slats are held by a picture frame that can be adjusted. It can compensate for a slightly uneven floor and tweak the plane as needed. The most common sizes for waterjet machine tools are 3×2 or 4×2 meters in the XY plane, so there is a lot of area to make level.

My favorite way to level the work surface upon installation is to level the slats to the water within the tank, and then do the same with the machine tool. Making everything level to the water is a simple way of aligning the entire system to the planet (old school, but effective).

So, be kind to your operator and QA department. Reduce rework and improve quality with a level material support surface. Hope this was helpful. Please send your thoughts and requests for future posts.