Cutting Metals with Waterjet

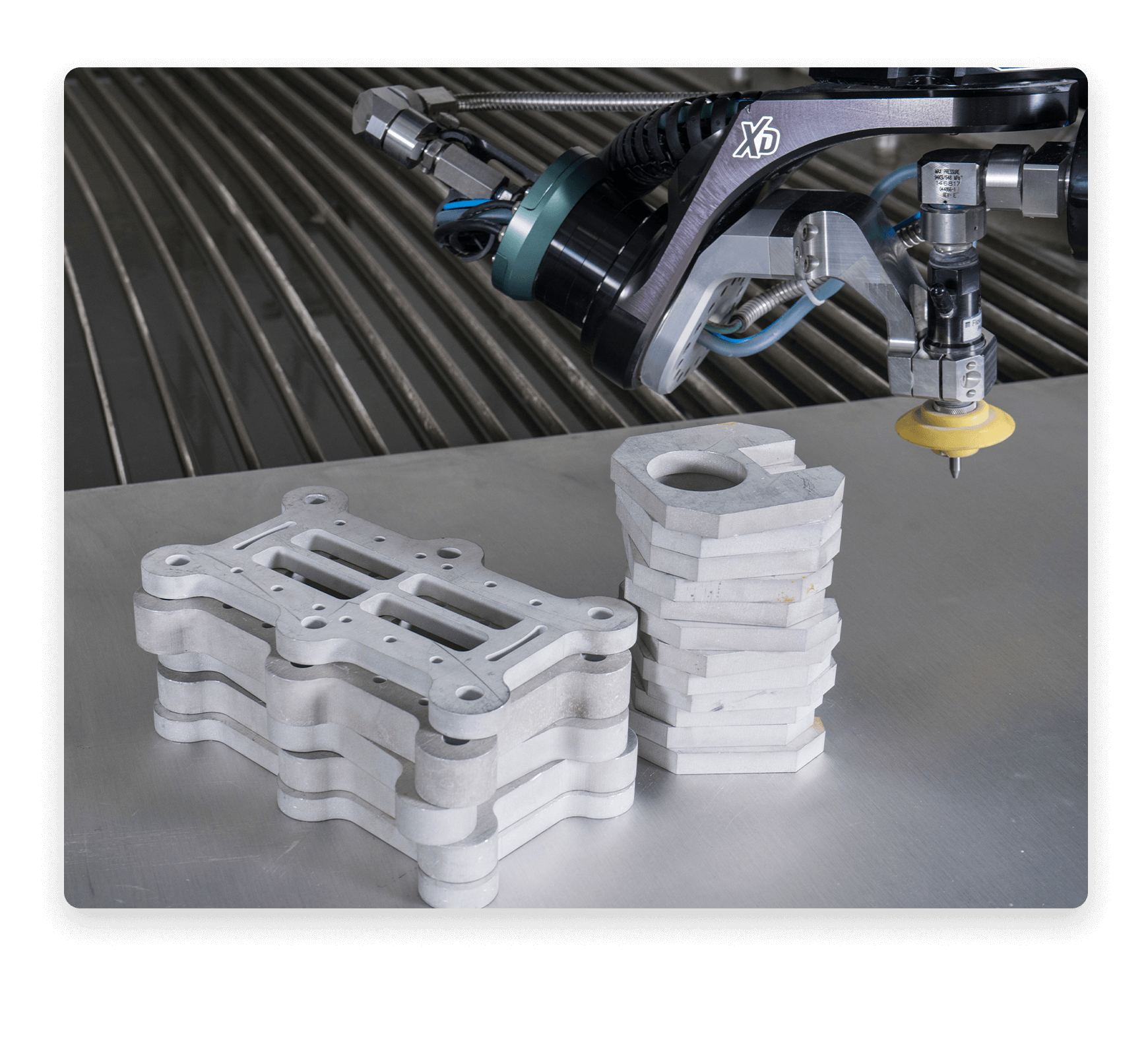

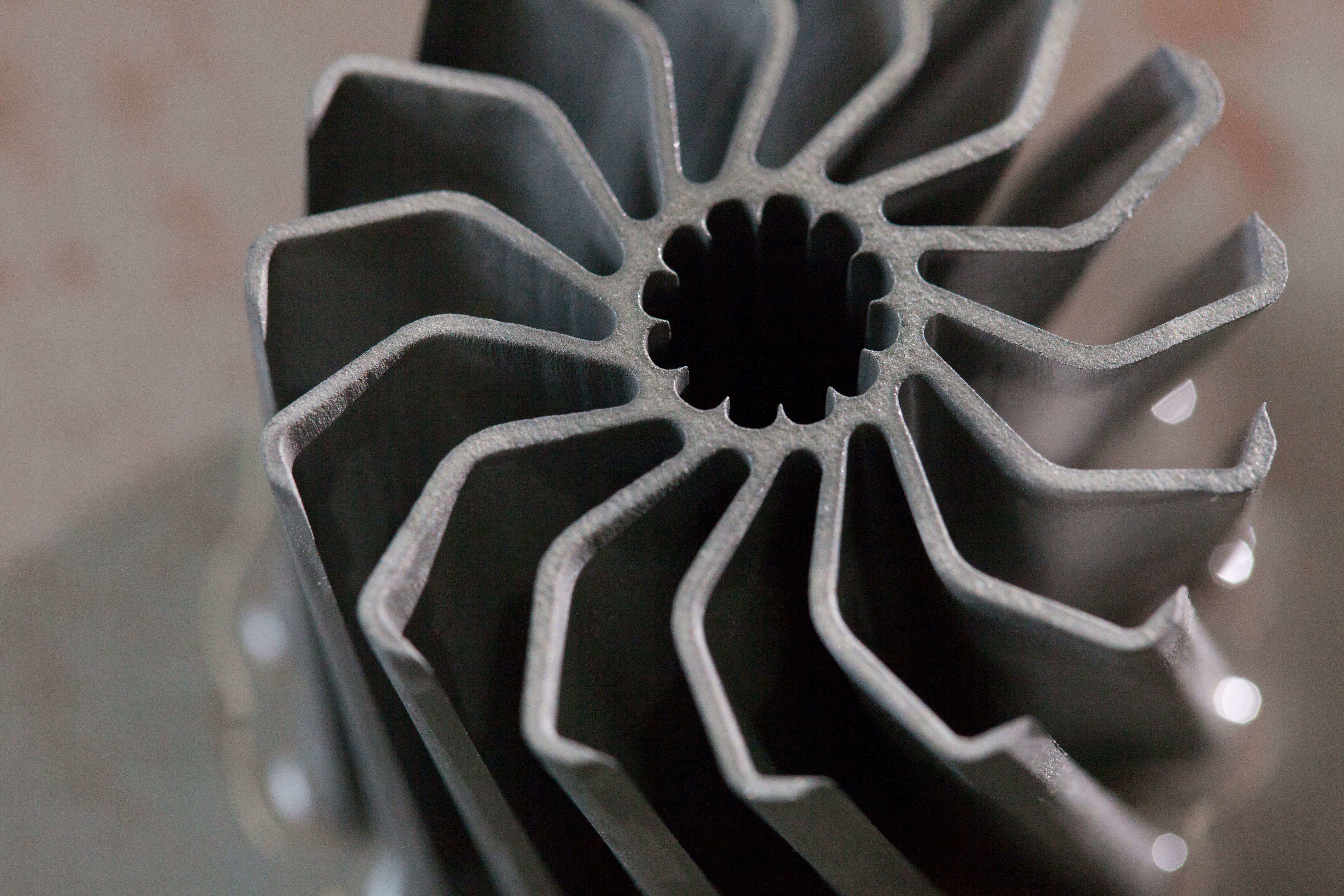

Abrasive waterjets are ideally suited for tough and lucrative applications for any metal cutting. More than just common materials of mild steel and aluminum, abrasive waterjets easily cut titanium, Inconel®, brass, and tool steel. Whether you're cutting 8 inch thick titanium or 1/4 inch aluminum, you'll discover that Flow waterjets are versatile enough to cut a variety of shapes and materials.Not sure a waterjet can handle your material?

The Best Edge

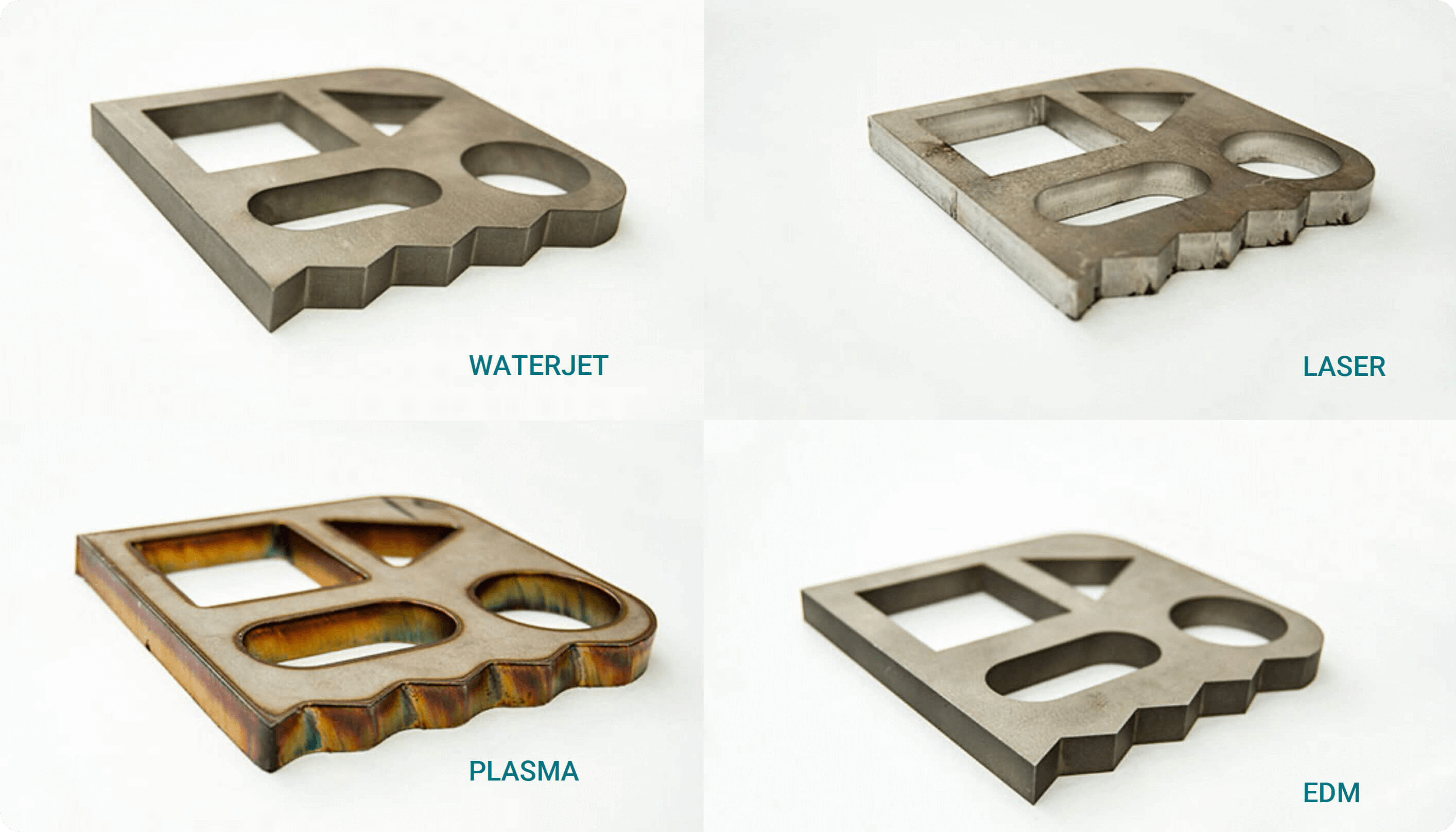

Because there is absolutely no mechanical stress, heat distortion or heat-affected zone (HAZ), secondary processing can usually be eliminated. Get a satin smooth edge directly off the waterjet table.

Minimal Kerfs

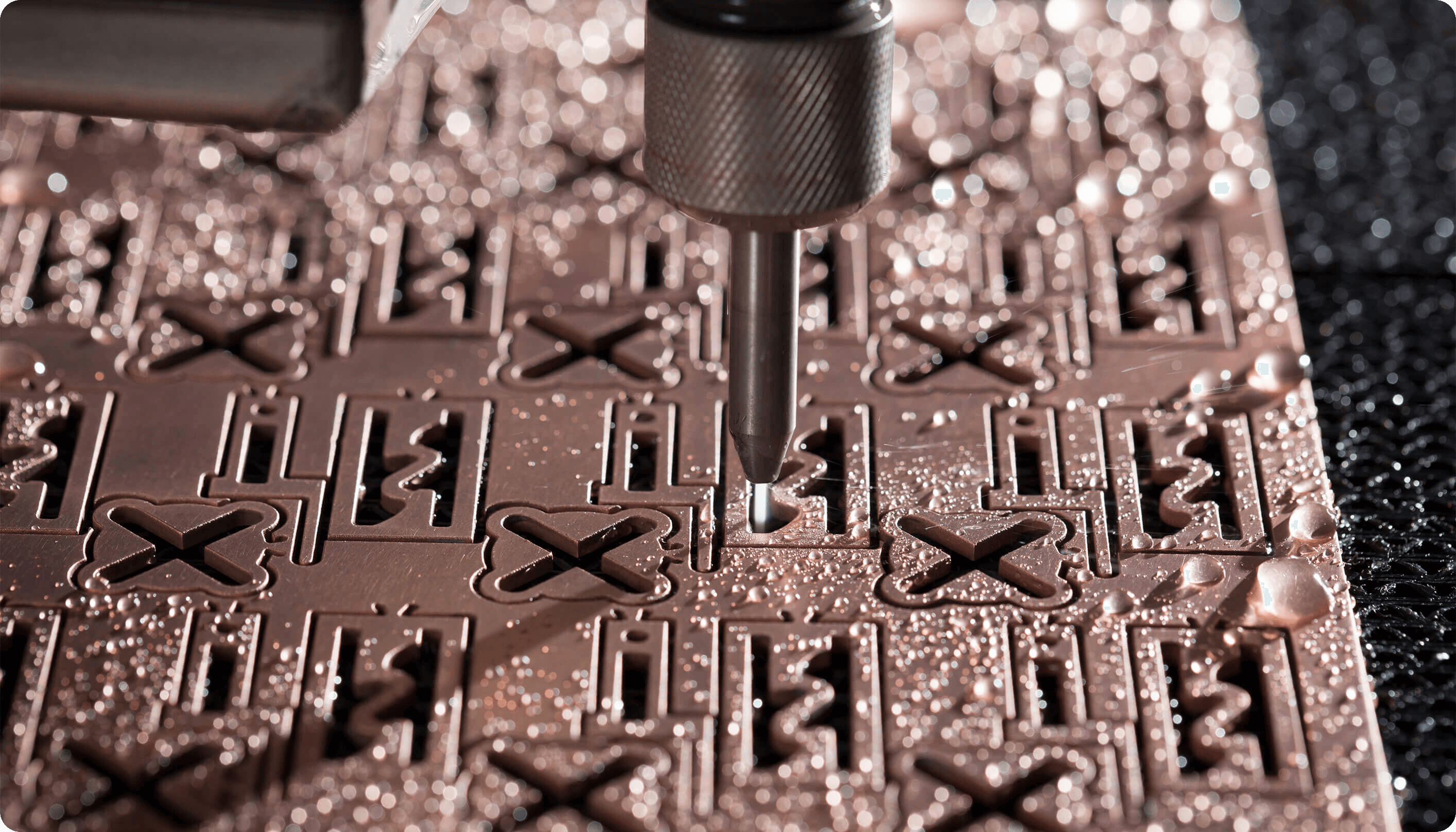

Because waterjets cut with a narrow kerf, usually 0.030" to 0.040", parts can be tightly nested or common-line cut so raw material usage is maximized. This means less scrap on your floor and more money in your pockets.

Key Benefits to Cutting Metals with Waterjet

- Increased productivity, fast cutting and high-quality parts

- Minimal kerf allows incredible detail

- Inconsistent material is not a problem (no need for expensive 'laser ready' material)

- Raw material savings — reduced scrap

- No need for extensive part clamping, minimal lateral or vertical forces

- Single-pass cutting, depending on material thickness

- No thermal damage

- Net or near-net cutting, little or no hand finishing