Dynamic Waterjet®

Produces More Accurate Parts, at Significantly Higher Cutting Speeds

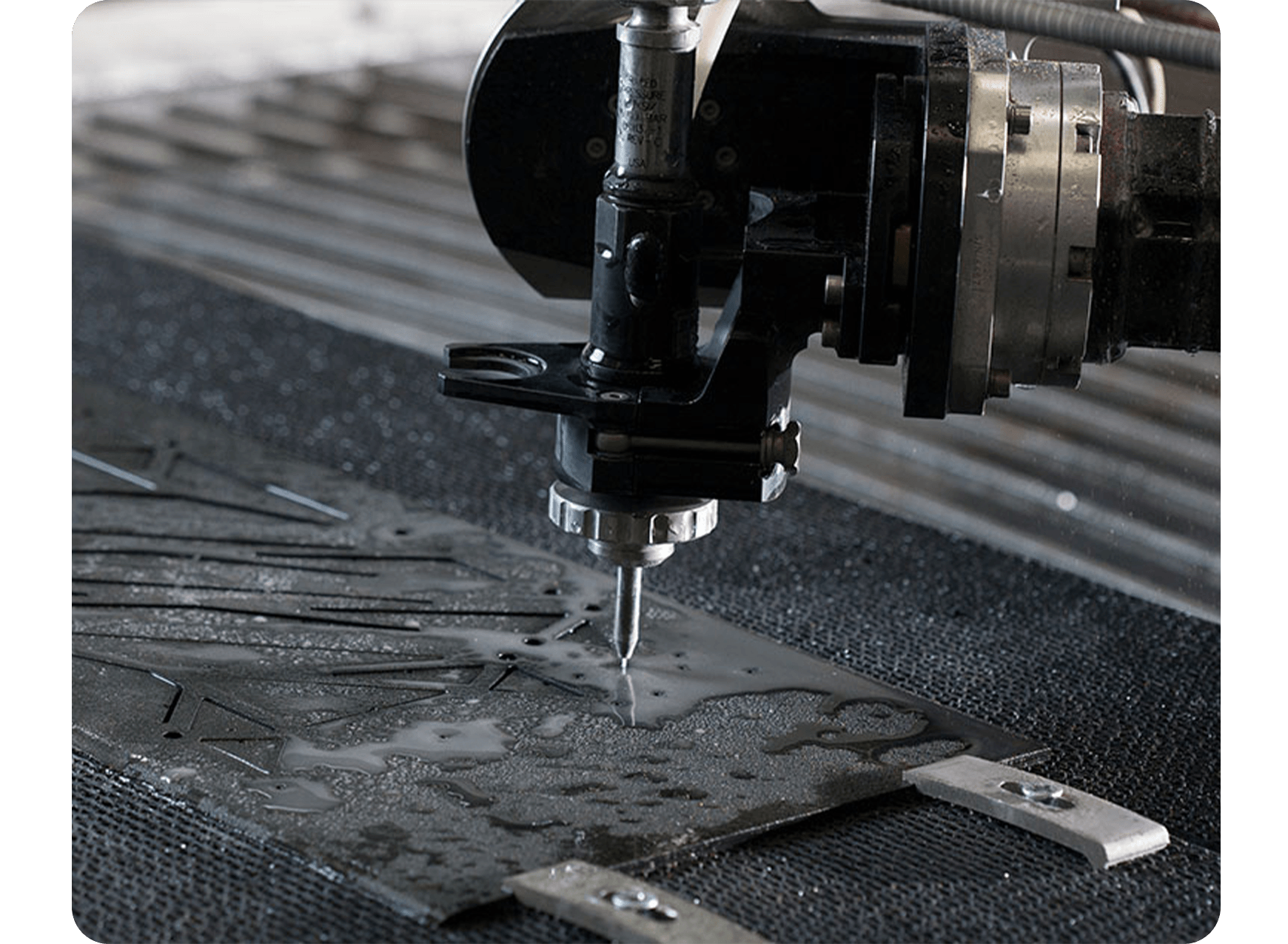

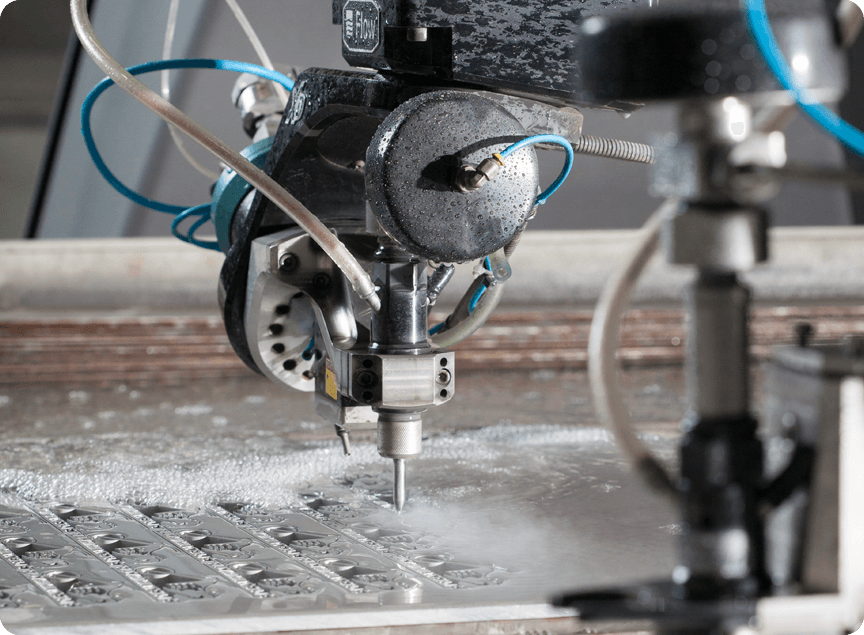

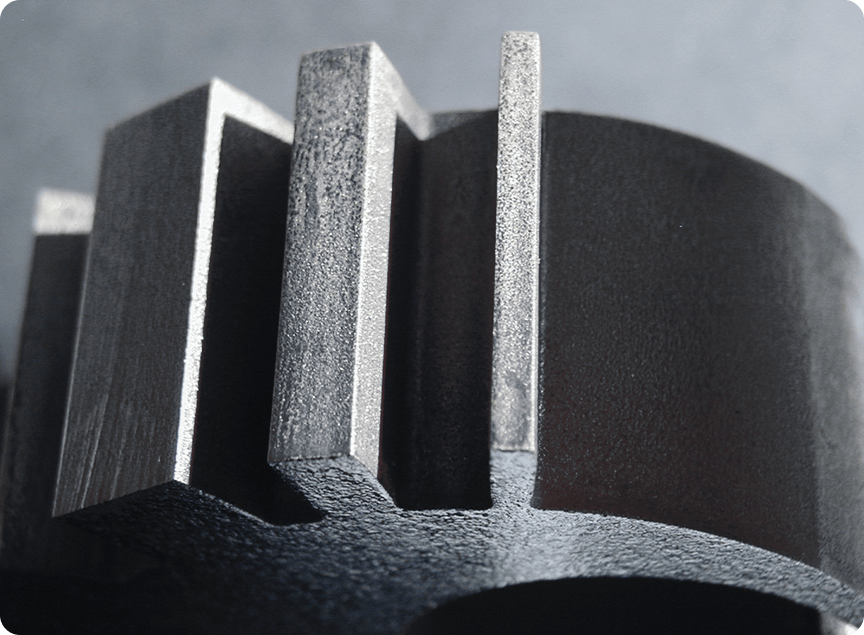

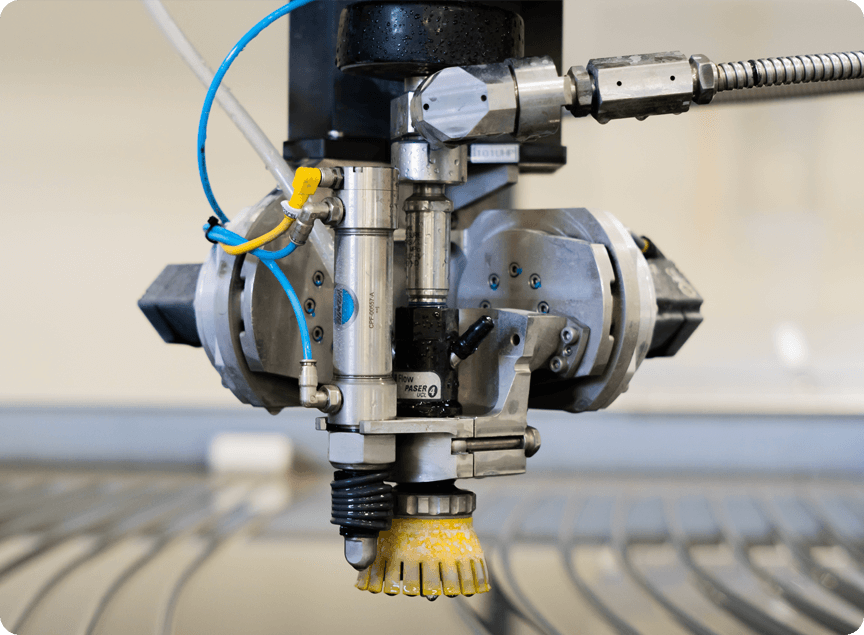

All waterjets exhibit stream lag and taper when cutting through material. Our patented Dynamic Waterjet® with Active Tolerance Control™ compensates for these inherent errors. Dynamic Waterjet produces more accurate parts at significantly higher cut speeds than parts cut with a standard waterjet. Utilizing advanced mathematical cutting models, SmartStream™ technology controls an articulated wrist to automatically tilt, compensating for the stream lag and taper.

Key Features

Productivity

Cut parts 2 to 4x faster than conventional flat stock waterjet cutting machines. In addition, achieve consistent tolerance layer to layer with true part stacking ability.

Quality

Gives you the ability to cut parts faster and more accurately than with a standard non-Dynamic waterjet.

Easy to Program

5-axis head articulations all occur behind the scenes automatically. No special training or waterjet cut part knowledge is required to gain the benefits of this technology.

Versatility

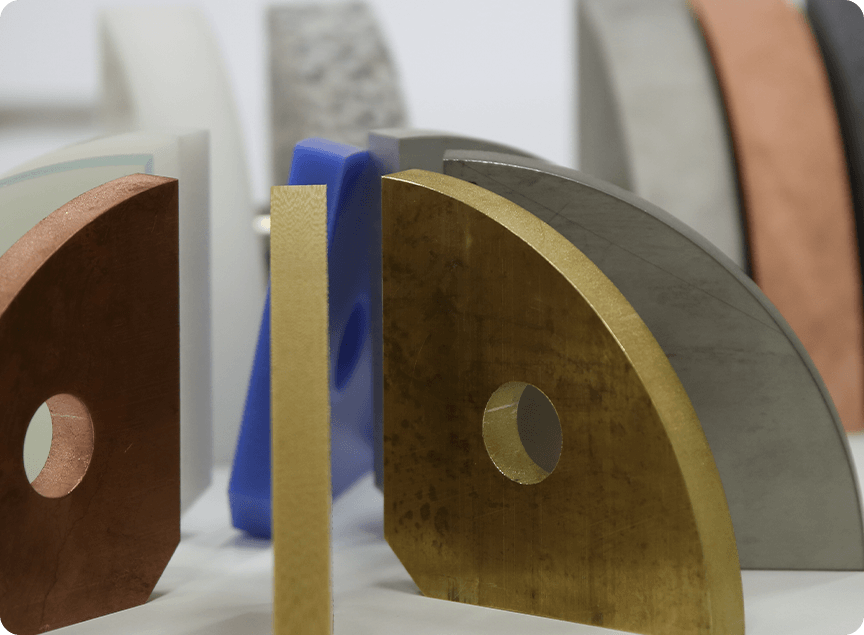

Like all Flow waterjets, cut a variety of materials, such as metal, stone, glass, and composites. The Z axis can also carry the pure waterjet cutting head, thereby providing the ability to cut soft materials on the same machine.

Specifications

FlowMaster Software

[with Dynamic Waterjet module]

+/- 10 degree

[5-axis kinematics with articulated A/B wrist]

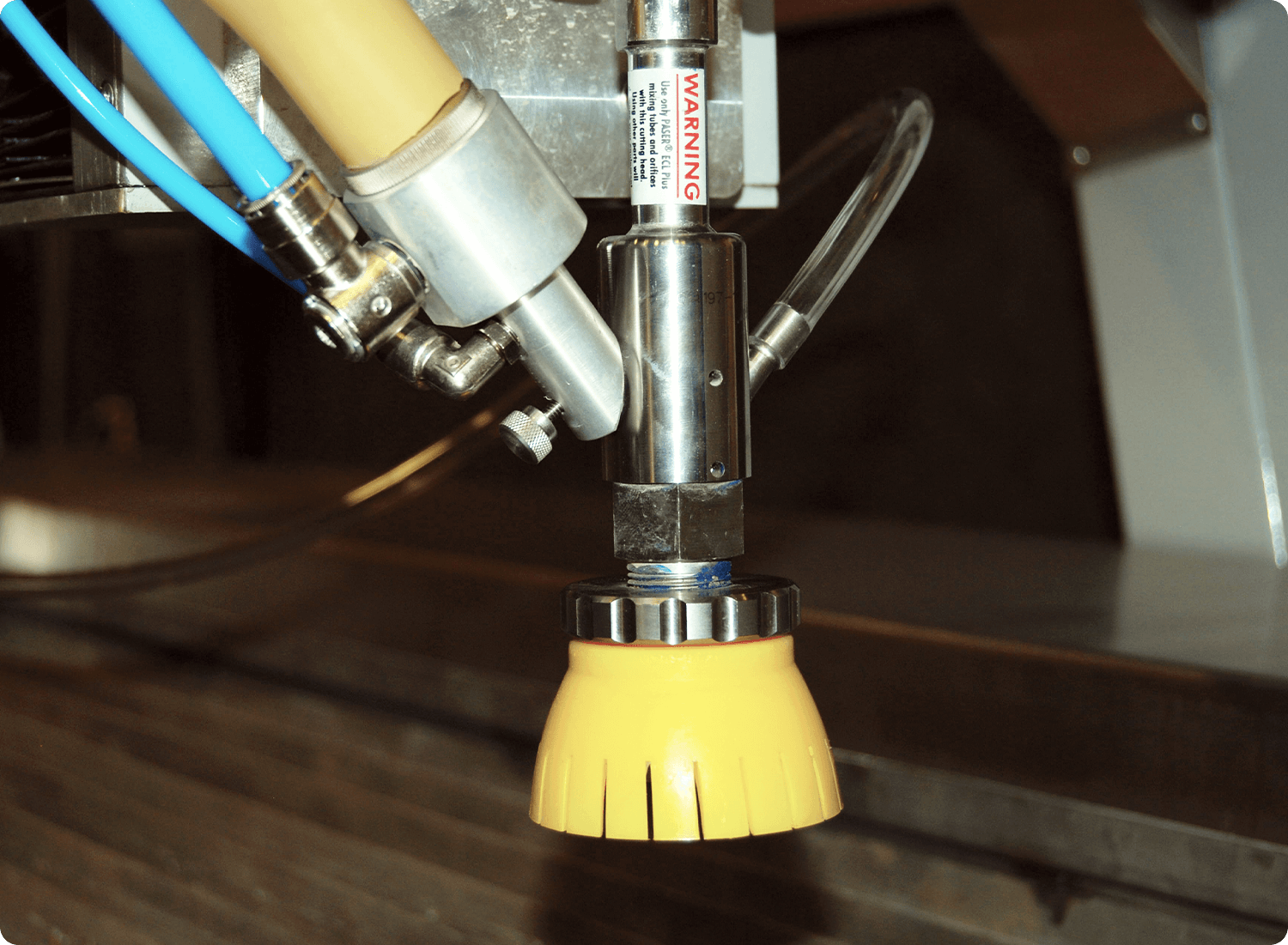

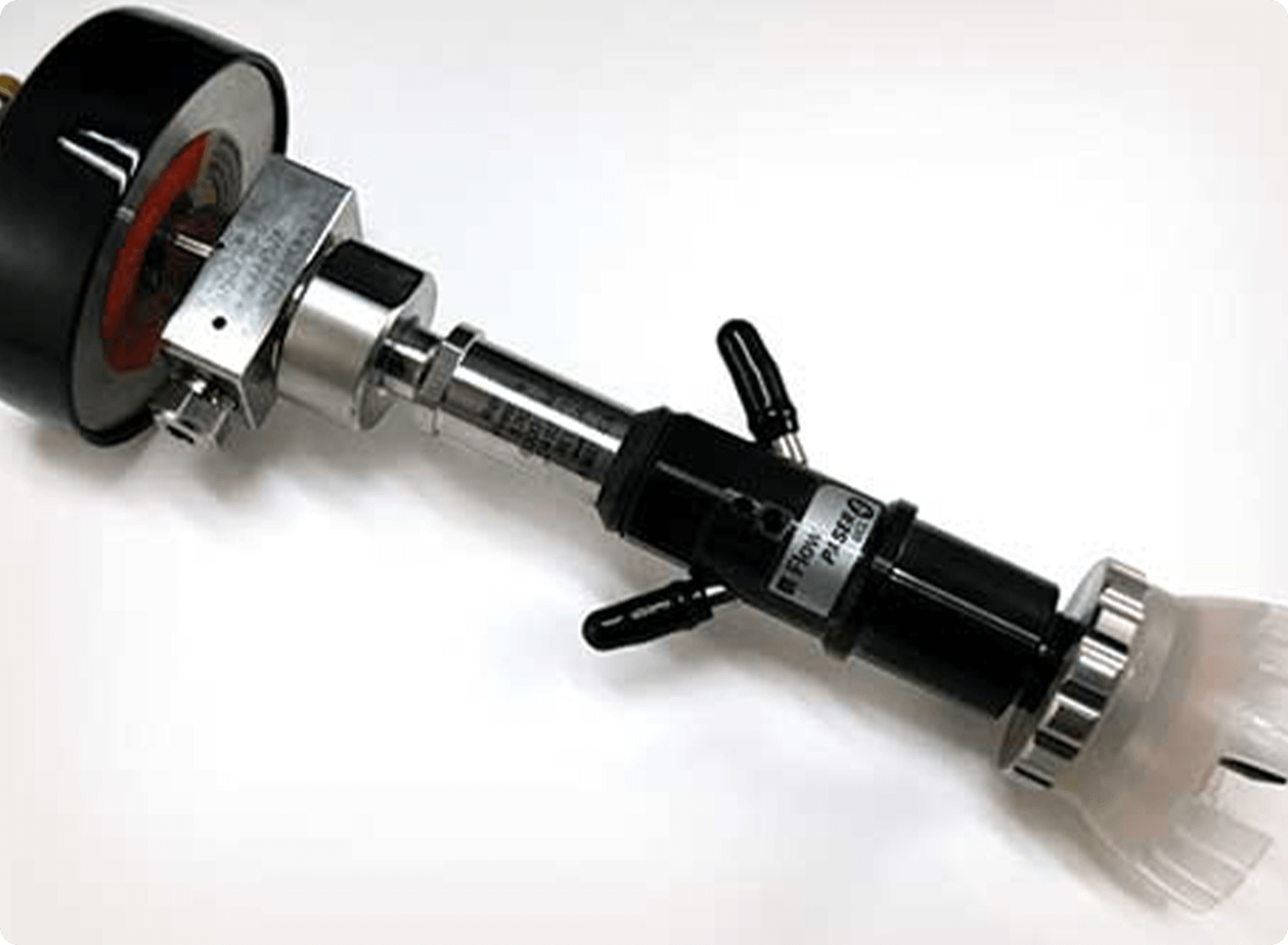

High-precision, quick-clamp to instantly and precisely attach or remove the Paser 4 or pure waterjet cutting heads

Touchdown Height Sensor

Establish proper standoff height

Core Component Options

PASER 4 Cutting Head

UltraPierce™ Vacuum Assist

Learn More